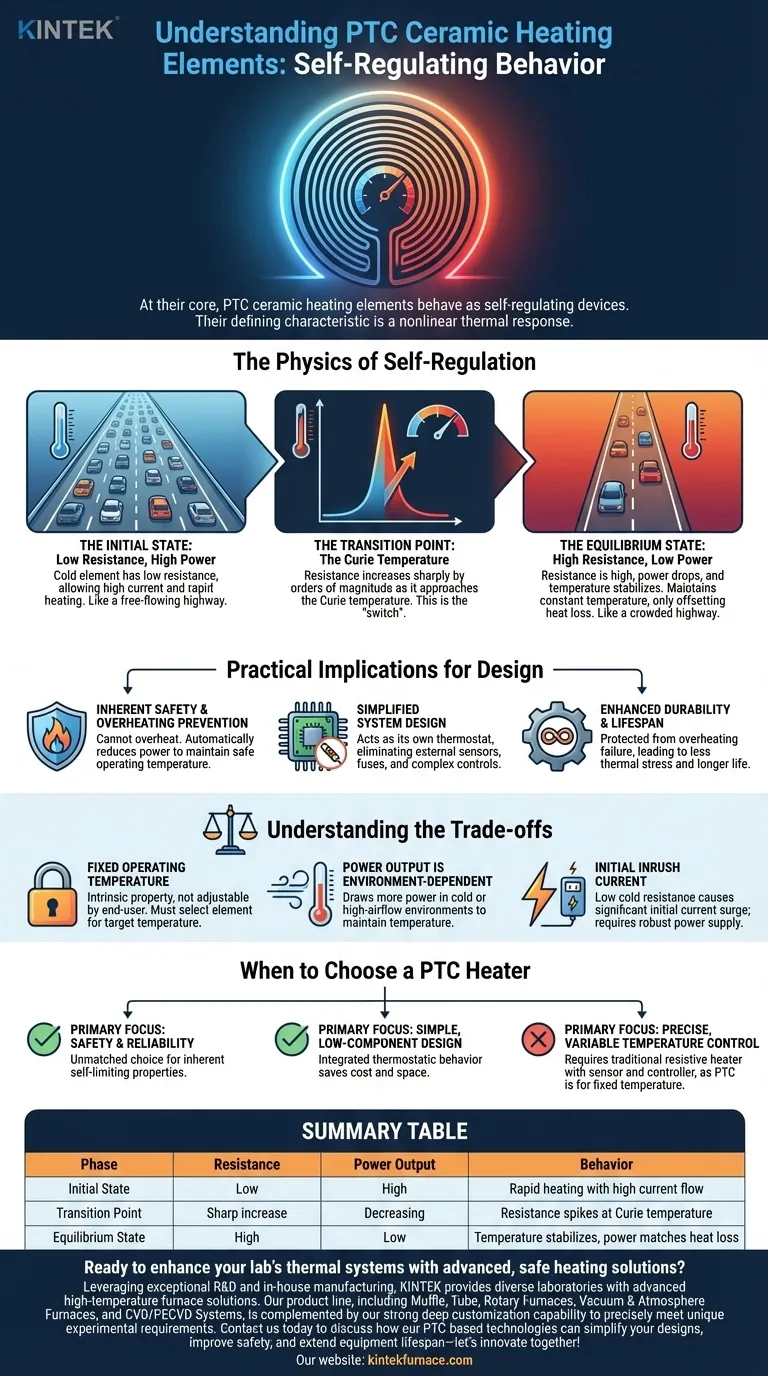

At their core, PTC ceramic heating elements behave as self-regulating devices. Their defining characteristic is a nonlinear thermal response: their electrical resistance is low when cold, allowing for rapid heating, but increases dramatically as they approach a specific temperature, automatically throttling the flow of current. This prevents the element from ever exceeding its designed operating temperature.

The most critical takeaway is that a PTC heater's physics make it intrinsically safe and stable. By acting as its own thermostat, it eliminates the risk of thermal runaway and simplifies system design, removing the need for external sensors or complex control circuits.

The Physics of Self-Regulation

The behavior of a Positive Temperature Coefficient (PTC) heater is governed by the unique properties of its ceramic material. This process can be understood in three distinct phases.

The Initial State: Low Resistance, High Power

When the PTC element is cold, its electrical resistance is very low. When voltage is applied, this low resistance allows a high current to flow through the device, resulting in a rapid generation of heat and a fast warm-up time.

Think of it as an open, multi-lane highway allowing maximum traffic (current) to flow freely.

The Transition Point: The Curie Temperature

As the element heats up, it approaches a specific, pre-determined point known as the Curie temperature. At this temperature, the material's crystalline structure changes, causing its electrical resistance to increase by several orders of magnitude in a very narrow temperature range.

This is the "switch" in the system. It is not a gradual increase but a sharp, dramatic spike in resistance that defines the heater's self-limiting capability.

The Equilibrium State: High Resistance, Low Power

Once the resistance has spiked, it becomes extremely difficult for current to pass through the ceramic element. The power output drops significantly, and the heater's temperature stabilizes just at or above its Curie point.

The element will now only draw enough power to offset the heat being lost to the environment, maintaining a constant temperature. The highway is now at a standstill, only allowing a few cars through to replace those that exit.

Practical Implications for Design

This self-regulating behavior translates into significant advantages when designing a product or system.

Inherent Safety and Overheating Prevention

The most significant benefit is safety. A PTC heater cannot overheat. Even if airflow is blocked or the ambient temperature rises, the element will automatically reduce its power output to maintain its safe, stable operating temperature.

Simplified System Design

Because the heating element serves as its own thermostat, you can often eliminate the need for external temperature sensors, fuses, and complex control circuitry. This reduces the bill of materials, simplifies assembly, and removes potential points of failure.

Enhanced Durability and Lifespan

Traditional resistance wire heaters can degrade or fail if they overheat. PTC elements are protected from this failure mode by their own physics, leading to less thermal stress and a significantly longer operational life.

Understanding the Trade-offs

While powerful, PTC technology is not universally applicable. Understanding its limitations is key to using it effectively.

Fixed Operating Temperature

The self-regulating temperature is an intrinsic property of the ceramic material. It cannot be adjusted by the end-user. You must select a PTC element designed specifically for your target temperature.

Power Output is Environment-Dependent

The power a PTC heater consumes is not constant. It draws high power when cold and low power when hot. In a very cold environment or one with high airflow, the heater will constantly work harder (drawing more power) to maintain its setpoint temperature. This dynamic power draw must be accounted for in your power supply design.

Initial Inrush Current

The low resistance of a cold PTC element can result in a significant inrush current when power is first applied. The power supply, traces, and wiring must be robust enough to handle this initial surge without damage or voltage drops.

When to Choose a PTC Heater

Selecting the right heating technology depends entirely on your project's goals.

- If your primary focus is safety and reliability: PTC heaters are an unmatched choice due to their inherent self-limiting properties that prevent overheating.

- If your primary focus is a simple, low-component-count design: The integrated thermostatic behavior of PTC elements eliminates the need for external control circuits, saving cost and space.

- If your primary focus is precise, variable temperature control: You will likely need a traditional resistive heater paired with a dedicated sensor and controller, as PTC elements are designed to stabilize at one specific temperature.

Ultimately, understanding a PTC heater's self-regulating nature empowers you to design safer, simpler, and more reliable thermal systems.

Summary Table:

| Phase | Resistance | Power Output | Behavior |

|---|---|---|---|

| Initial State | Low | High | Rapid heating with high current flow |

| Transition Point | Sharp increase | Decreasing | Resistance spikes at Curie temperature |

| Equilibrium State | High | Low | Temperature stabilizes, power matches heat loss |

Ready to enhance your lab's thermal systems with advanced, safe heating solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our PTC-based technologies can simplify your designs, improve safety, and extend equipment lifespan—let's innovate together!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions