In specialized industries, composite heating elements serve a critical role by providing highly durable and precisely controlled heating solutions engineered to withstand conditions where standard heaters would fail. They combine different materials to create a custom component with superior resistance to harsh chemicals and the ability to integrate perfectly into complex industrial equipment.

The core problem is that standard metal or ceramic heaters are general-purpose tools that cannot meet the extreme demands of specialized applications. Composite heating elements solve this by merging the properties of multiple materials into a single, optimized component built for a specific purpose.

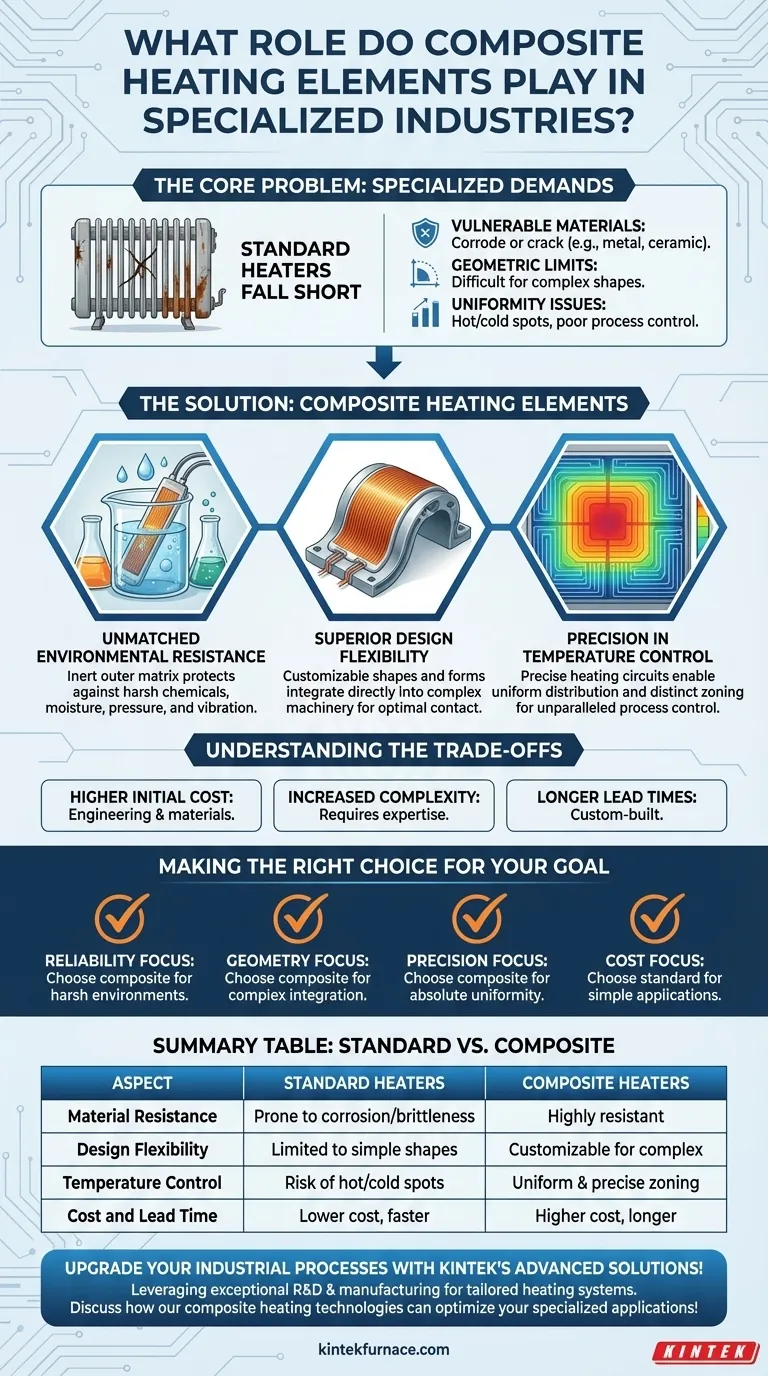

Why Standard Heaters Fall Short

Traditional heating elements, while effective for general use, have inherent limitations that make them unsuitable for many high-stakes industrial processes. Understanding these constraints is key to appreciating the value of a composite approach.

The Limits of Conventional Materials

Standard heaters are typically made from a single class of material, like metal alloys or ceramics. While robust, they present specific vulnerabilities. Metal heaters can corrode in chemically aggressive environments, and ceramics can be brittle and susceptible to thermal shock.

The Problem of Geometry

Specialized industrial machinery, from chemical reactors to aerospace components, rarely has simple, flat surfaces. Standard off-the-shelf heaters are difficult to integrate into these complex, custom geometries, leading to inefficient heat transfer and potential equipment damage.

The Challenge of Uniform Heating

Achieving a perfectly uniform temperature across a complex surface is extremely difficult with standard elements. This can lead to hot spots and cold spots, compromising sensitive processes like chemical synthesis or semiconductor manufacturing where precise thermal consistency is mandatory.

The Core Advantages of Composite Heaters

Composite elements are not just heaters; they are engineered solutions. By embedding a resistive heating element within a protective and formable matrix (like a polymer or ceramic composite), they overcome the limitations of their traditional counterparts.

Unmatched Environmental Resistance

The outer material of a composite heater is chosen specifically to protect the internal heating element. This matrix can be designed to be completely inert to corrosive chemicals, resistant to moisture, and capable of withstanding extreme pressures and vibrations.

Superior Design Flexibility

Because they are often created through molding or layering processes, composite heaters can be manufactured in virtually any shape. This allows them to be integrated directly into complex parts, ensuring direct and efficient contact for optimal heat transfer.

Precision in Temperature Control

The design of a composite heater allows for the precise placement of heating circuits within the material. This enables highly uniform heat distribution or, if needed, the creation of distinct heating zones with different temperatures on a single component, offering an unparalleled level of process control.

Understanding the Trade-offs

While powerful, composite heating elements are a specialized solution with specific considerations. Objectivity requires acknowledging their potential downsides compared to conventional options.

Higher Initial Cost

The custom engineering, advanced materials, and specialized manufacturing processes involved make composite heaters more expensive upfront than standard, mass-produced elements. This cost, however, is often justified by increased process yield, lower maintenance, and greater reliability.

Increased Design Complexity

Creating an effective composite heater is not a simple task. It requires significant expertise in materials science and thermal engineering to select the right combination of materials and design the internal circuitry to meet the application's demands.

Longer Lead Times

Unlike off-the-shelf heaters, composite solutions are custom-built for each application. This bespoke nature means that design, prototyping, and manufacturing cycles are inherently longer.

Making the Right Choice for Your Goal

The decision to use a composite heater should be driven by the specific demands of your application.

- If your primary focus is reliability in a harsh chemical or high-moisture environment: A composite heater is the superior choice for ensuring longevity and preventing corrosion-related failure.

- If your primary focus is integrating heat into a geometrically complex part: The design flexibility of composite elements allows for a perfectly conformed fit that standard heaters cannot match.

- If your primary focus is absolute temperature uniformity for a sensitive process: Composite heaters provide the most precise and consistent thermal distribution available.

- If your primary focus is a low-cost solution for a simple, non-critical application: A traditional metal or ceramic heater remains the most economical and straightforward option.

By evaluating your core engineering challenges, you can confidently determine if a composite heating element is the right strategic investment for your project.

Summary Table:

| Aspect | Standard Heaters | Composite Heaters |

|---|---|---|

| Material Resistance | Prone to corrosion and brittleness | Highly resistant to chemicals, moisture, and thermal shock |

| Design Flexibility | Limited to simple shapes | Customizable for complex geometries |

| Temperature Control | Risk of hot/cold spots | Uniform heating and precise zoning |

| Cost and Lead Time | Lower cost, faster delivery | Higher initial cost, longer lead times |

Upgrade your industrial processes with KINTEK's advanced high-temperature furnace solutions!

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored heating systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental requirements, enhancing reliability and efficiency in harsh environments.

Contact us today to discuss how our composite heating technologies can optimize your specialized applications!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights