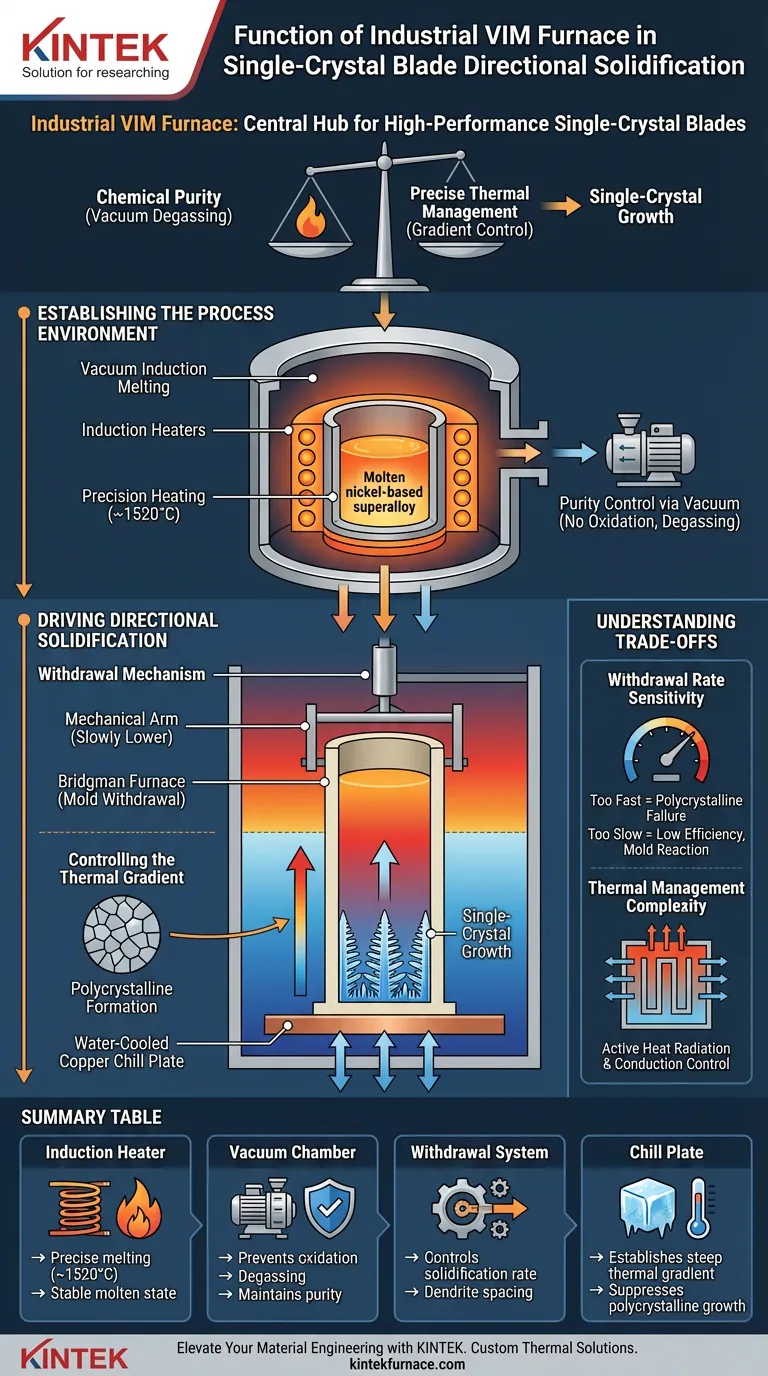

The industrial vacuum induction melting (VIM) furnace functions as the central processing hub for creating high-performance single-crystal blades. It integrates a high-power precision heating chamber to maintain nickel-based superalloys in a fully molten state, typically around 1520°C, with a mechanical mold withdrawal system. By operating within a strict vacuum, it simultaneously prevents alloy oxidation and manages the critical thermal gradient required for controlled directional solidification.

Core Insight: The VIM furnace is not merely a melting vessel; it is a complex environment regulator. Its primary value lies in its ability to couple chemical purity—achieved through vacuum degassing—with the precise thermal management necessary to suppress polycrystalline formation and ensure single-crystal growth.

Establishing the Process Environment

Precision Heating and Melting

The VIM furnace utilizes powerful induction heaters (e.g., 125 kW) to generate high-frequency electromagnetic fields.

This energy brings the metal, often a nickel-based superalloy, to extreme temperatures such as 1520°C while maintaining a stable, fully molten state.

Purity Control via Vacuum

A critical function of the furnace is maintaining a low-pressure vacuum environment throughout the melting and pouring process.

This prevents the oxidation of reactive alloy components, which is fatal to the structural integrity of a turbine blade.

Furthermore, the vacuum facilitates the removal of gaseous impurities like oxygen and nitrogen, ensuring the chemical composition remains precise and free of contaminants.

Driving Directional Solidification

The Withdrawal Mechanism

Once the alloy is molten, the furnace acts as a Bridgman furnace to initiate solidification.

The system uses a precision mechanism to withdraw the mold containing the molten metal from the high-temperature heating zone into a cooling zone.

This movement is not random; the rate of withdrawal is the primary variable controlling the quality of the single crystal.

Controlling the Thermal Gradient

As the mold moves toward a water-cooled copper chill plate, a steep temperature gradient is established.

This gradient dictates the direction of crystal growth and determines the primary dendrite arm spacing.

By maintaining this gradient, the furnace forces the metal to solidify in a single, continuous crystal structure, effectively suppressing the formation of random, polycrystalline grains.

Understanding the Trade-offs

Sensitivity to Withdrawal Rates

The integration of melting and withdrawal creates a highly sensitive process window.

If the withdrawal rate is too fast, the thermal gradient collapses, leading to immediate polycrystalline formation and part failure.

If the rate is too slow, production efficiency drops, and the risk of reaction between the molten metal and the ceramic mold increases.

Complexity of Thermal Management

Achieving the correct liquidus isotherm curvature requires sophisticated baffle designs and cooling systems.

Unlike standard casting, the VIM process for single crystals cannot rely on passive cooling; it requires active, dynamic management of heat radiation and conduction to prevent structural defects.

Making the Right Choice for Your Goal

The VIM furnace is a sophisticated tool that balances chemical science with thermal physics. Depending on your specific manufacturing priorities, your focus on the furnace's capabilities will differ.

- If your primary focus is Alloy Purity: Prioritize the vacuum chamber's integrity and pressure control to ensure the effective removal of gaseous impurities and prevention of oxidative loss.

- If your primary focus is Microstructure Control: Focus on the precision of the withdrawal system and the cooling zone design to maintain the steep thermal gradient required for optimal dendrite spacing.

Success in single-crystal production relies on treating the furnace not just as a heat source, but as an instrument for precise microstructural engineering.

Summary Table:

| Key Component | Primary Function | Impact on Single-Crystal Quality |

|---|---|---|

| Induction Heater | Precise melting of nickel-based alloys (~1520°C) | Ensures stable molten state for uniform pouring |

| Vacuum Chamber | Prevention of oxidation and degassing | Maintains chemical purity and structural integrity |

| Withdrawal System | Mechanical mold movement into cooling zone | Controls solidification rate and dendrite spacing |

| Chill Plate | Establishing steep thermal gradient | Suppresses polycrystalline formation for single-crystal growth |

Elevate Your Material Engineering with KINTEK

Precision is the difference between a failed casting and a high-performance turbine component. At KINTEK, we specialize in providing cutting-edge thermal solutions tailored for the most demanding industrial applications.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Vacuum, CVD, Muffle, Tube, and Rotary systems, all of which are fully customizable to meet your unique directional solidification and melting requirements. Our lab high-temp furnaces are designed to give you the ultimate control over thermal gradients and atmospheric purity.

Ready to optimize your production quality? Contact us today to discuss your custom furnace needs with our engineering experts.

Visual Guide

References

- Dariusz Szeliga, Artur Wiechczyński. Directional Solidification of Single-Crystal Blades in Industrial Conditions Using the Developed Gas Cooling Casting Method. DOI: 10.1007/s11661-024-07391-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- How does induction heating work in a vacuum environment? Achieve High-Purity, Contamination-Free Heat Treatment

- How does a vacuum induction furnace work? Achieve Ultra-Clean Metal Melting for Superior Alloys

- What are the advantages of vacuum induction melting and casting (VIM&C) over VIM? Achieve Superior Metallurgical Quality and Efficiency

- Why is the choice of crucible important in an induction furnace? Ensure Melt Purity and Process Safety

- Why are IGBT modules preferred in melting machines? Unlock Faster Melting & Lower Costs

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the advantages of using an IGBT induction melting machine? Boost Efficiency & Quality

- What technical advantages does a Vacuum Arc Melting Furnace provide? Master Sulfur-Doped Copper Alloy Purity