The defining advantages of an IGBT induction melting machine are its superior energy efficiency, rapid melting speed, and precise process control. These benefits stem directly from its use of modern Insulated Gate Bipolar Transistor (IGBT) technology, which allows for more effective power conversion compared to older methods.

At its core, the choice to use an IGBT-based system is about more than just melting metal. It represents a strategic shift towards lower operational costs, higher metallurgical quality, and greater long-term reliability for your entire melting operation.

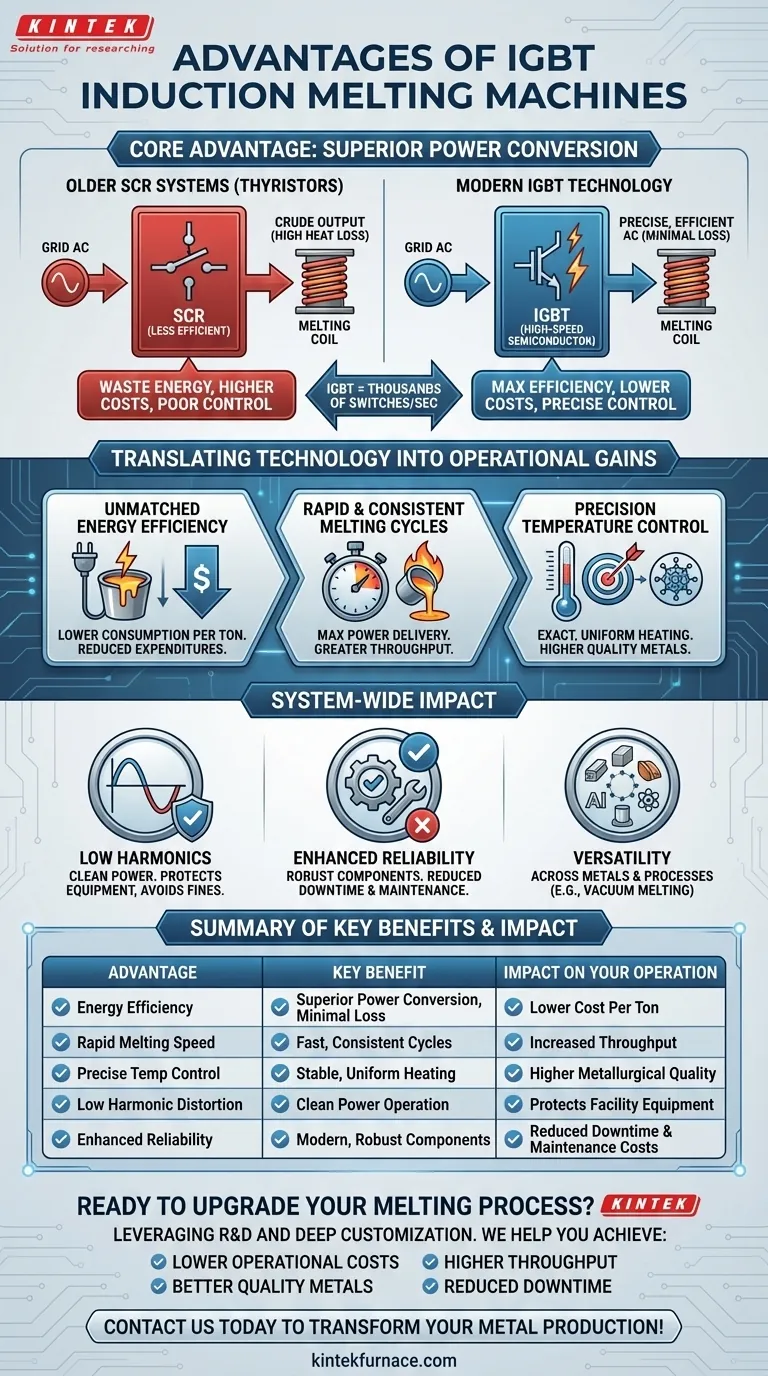

The Core Advantage: Superior Power Conversion

The "IGBT" in the name is the key differentiator. Understanding what it does reveals why these furnaces are a significant technological leap forward.

What is IGBT Technology?

An Insulated Gate Bipolar Transistor, or IGBT, is a sophisticated, high-speed power semiconductor. Think of it as an incredibly fast and efficient electronic switch.

In an induction furnace, its job is to take incoming AC power from the grid and convert it into the precise high-frequency AC power needed to generate a powerful magnetic field for melting.

Why It Matters for Induction Heating

The efficiency of this power conversion process dictates the performance of the entire system. IGBTs can switch on and off thousands of times per second with minimal energy loss.

This rapid switching gives the system precise control over both the frequency and the amount of power delivered to the melt. This level of control is simply not possible with older technologies.

The Contrast with Older SCR Systems

Many older induction furnaces use Silicon-Controlled Rectifiers (SCRs), also referred to as thyristors. While functional, SCRs are less efficient and operate more crudely.

They waste more energy as heat during the power conversion process and offer far less precise control over the output frequency. This leads to higher energy bills and less optimal melting performance.

Translating Technology into Operational Gains

The theoretical benefits of IGBTs translate directly into tangible improvements on the production floor.

Unmatched Energy Efficiency

Because IGBTs waste very little energy during power conversion, more of the electricity you pay for is used to actually melt the metal.

This results in significantly lower energy consumption per ton of metal melted, directly reducing your operational expenditures.

Rapid and Consistent Melting Cycles

The high efficiency of the power unit allows the furnace to deliver maximum power to the coil. This creates a strong magnetic field that heats and melts the charge material incredibly quickly.

Faster melting cycles mean greater throughput, allowing you to produce more in less time.

Precision Temperature Control for Higher Quality

IGBT controls allow for exact and stable power output. This ensures uniform heating and enables the system to hold the molten metal at a precise temperature.

This level of control is critical for meeting stringent quality standards, reducing metal loss from oxidation, and ensuring the final product has the desired metallurgical properties.

Understanding the System-Wide Impact

The advantages of an IGBT furnace extend beyond the crucible and affect your entire facility's infrastructure and maintenance planning.

The Clean Power Advantage: Low Harmonics

A major drawback of older SCR-based systems is harmonic distortion. This is a form of electrical "noise" that pollutes your facility's power grid and can even affect the public utility grid.

Harmonics can interfere with other sensitive electronic equipment and may lead to fines from your power provider. IGBT systems operate cleanly with very low harmonic distortion, eliminating this problem entirely.

Enhanced Reliability and Reduced Downtime

IGBT power supplies are built with robust, modern components that are less prone to failure than the complex circuits in older SCR units.

This inherent reliability means less maintenance, fewer unexpected breakdowns, and more operational uptime for your production schedule.

Versatility Across Metals and Processes

The precise control offered by IGBT technology makes these furnaces highly versatile. They can efficiently melt a wide range of ferrous and non-ferrous metals, including steel, stainless steel, copper, brass, and aluminum alloys.

This technology also enables advanced metallurgical processes, such as vacuum induction melting, where the magnetic field must work through a non-conductive vacuum chamber to melt reactive metals in a controlled atmosphere.

Making the Right Choice for Your Operation

Choosing the right melting technology is a critical investment. Your decision should align with your most important operational goals.

- If your primary focus is maximizing throughput and lowering energy costs: The superior efficiency and rapid melting speed of an IGBT furnace provide the most direct path to a lower cost per ton.

- If your primary focus is achieving stringent metallurgical quality: The precise and stable temperature control of an IGBT system is essential for producing high-grade alloys and minimizing defects.

- If your primary focus is modernizing an aging facility or building new: An IGBT system's low harmonic distortion and high reliability will reduce long-term infrastructure and maintenance burdens.

Ultimately, investing in an IGBT induction furnace is a decision to adopt a more controlled, efficient, and reliable melting process for the future.

Summary Table:

| Advantage | Key Benefit | Impact on Your Operation |

|---|---|---|

| Energy Efficiency | Superior power conversion with minimal energy loss | Lower cost per ton of metal melted |

| Rapid Melting Speed | Fast, consistent melting cycles | Increased throughput and productivity |

| Precise Temperature Control | Stable, uniform heating | Higher metallurgical quality and reduced oxidation |

| Low Harmonic Distortion | Clean power operation | Protects facility equipment and avoids utility fines |

| Enhanced Reliability | Modern, robust components | Reduced downtime and maintenance costs |

Ready to Upgrade Your Melting Process?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse foundries and metalworking facilities with advanced IGBT induction melting solutions. Our product line, including standard and custom induction furnaces, is complemented by our strong deep customization capability to precisely meet your unique production requirements.

We help you achieve:

- Lower operational costs through superior energy efficiency

- Higher throughput with rapid, consistent melting cycles

- Better quality metals with precise temperature control

- Reduced downtime with reliable, modern technology

Contact us today to discuss how our IGBT induction melting machines can transform your metal production!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys