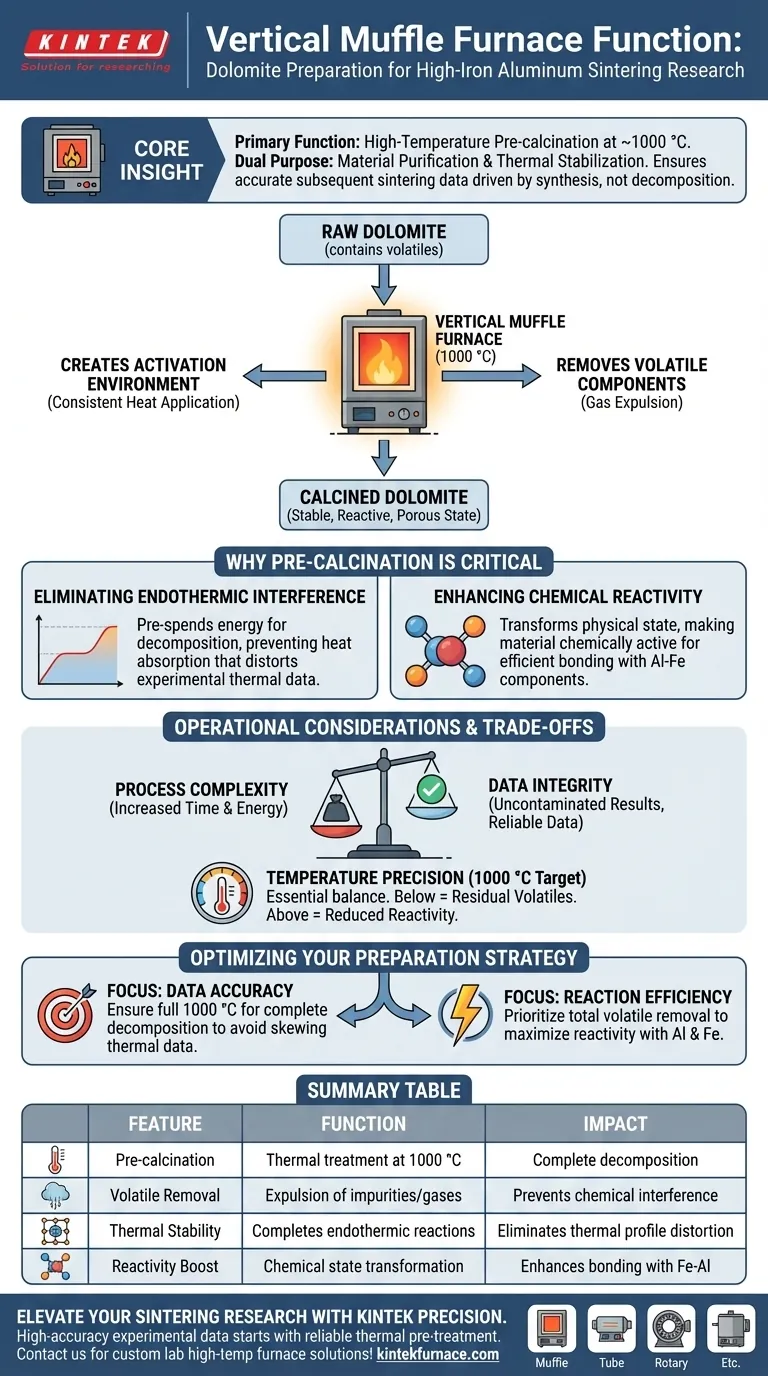

The primary function of a vertical muffle furnace in the preparation of dolomite is to facilitate high-temperature pre-calcination. Specifically, the furnace maintains a controlled environment at approximately 1000 °C to thermally treat raw dolomite before it is introduced to the high-iron aluminum sintering process.

Core Insight The furnace serves a dual purpose: material purification and thermal stabilization. By removing volatiles and completing necessary endothermic reactions early, it ensures that the subsequent sintering phase is driven purely by synthesis rather than decomposition, guaranteeing the accuracy of your experimental data.

The Mechanics of Thermal Pre-Treatment

Creating the Activation Environment

The vertical muffle furnace provides the specific thermal energy required to alter the chemical structure of dolomite.

At 1000 °C, the furnace ensures the material reaches the threshold necessary for complete thermal decomposition. This consistent heat application is the foundational step for preparing raw minerals for complex sintering tasks.

Removal of Volatile Components

Raw dolomite contains significant volatile matter that must be expelled prior to sintering.

The furnace drives off these impurities, primarily in the form of gas. Eliminating these volatiles prevents them from interfering with the delicate chemical balances required during the high-iron aluminum sintering phase.

Why Pre-Calcination is Critical

Eliminating Endothermic Interference

One of the most critical functions of the furnace is to "pre-spend" the energy required for decomposition.

If raw dolomite were used directly in sintering, it would undergo endothermic reactions (absorbing heat) inside the sintering vessel. This would distort the thermal profile of the experiment. Pre-calcination ensures these heat-absorbing reactions are completed beforehand.

Enhancing Chemical Reactivity

The heat treatment transforms the physical state of the dolomite to make it more chemically active.

By converting the raw mineral into a calcined state, the furnace significantly enhances the chemical reactivity of the material. This ensures that when the dolomite meets the high-iron aluminum components, the sintering reaction is efficient and robust.

Operational Considerations and Trade-offs

Process Complexity vs. Data Integrity

Using a vertical muffle furnace adds a significant step to the preparation workflow, increasing time and energy consumption.

However, skipping this step introduces variables that compromise data reliability. The trade-off is an investment of preparation time in exchange for uncontaminated experimental results.

Temperature Precision

The specific target of 1000 °C is not arbitrary; it balances complete decomposition with material integrity.

Operating below this temperature risks leaving residual volatiles that will outgas during sintering. Conversely, excessive temperatures could potentially alter the microstructure in ways that reduce reactivity, making precise furnace control essential.

Optimizing Your Preparation Strategy

To ensure your high-iron aluminum sintering research yields valid results, consider your specific objectives when utilizing the furnace:

- If your primary focus is Data Accuracy: Ensure the dolomite reaches the full 1000 °C to completely eliminate endothermic reactions that would skew your thermal data during sintering.

- If your primary focus is Reaction Efficiency: Prioritize the removal of all volatile components to maximize the chemical reactivity of the dolomite when it mixes with aluminum and iron sources.

By isolating the decomposition process in the muffle furnace, you transform a raw, unpredictable mineral into a stable, reactive ingredient ready for precise scientific synthesis.

Summary Table:

| Feature | Function in Dolomite Preparation | Impact on Research |

|---|---|---|

| Pre-calcination | Thermal treatment at 1000 °C | Ensures complete decomposition of raw minerals |

| Volatile Removal | Expulsion of impurities/gases | Prevents chemical interference during sintering |

| Thermal Stability | Completes endothermic reactions | Eliminates thermal profile distortion in experiments |

| Reactivity Boost | Chemical state transformation | Enhances bonding with iron-aluminum components |

Elevate Your Sintering Research with KINTEK Precision

High-accuracy experimental data starts with reliable thermal pre-treatment. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of material science. Our vertical muffle furnaces offer the precise temperature control and uniform heating essential for calcining dolomite and other minerals without compromising microstructure.

Backed by expert R&D and manufacturing, we specialize in customizable lab high-temp furnaces tailored to your unique research needs. Ensure your sintering synthesis is driven by science, not decomposition variables.

Ready to optimize your lab's thermal processes? Contact us today to find your custom furnace solution!

Visual Guide

References

- Seong‐Jin Kim, Sung‐Mo Jung. Effect of Mill-Scale and Calcined Dolomite on High Al2O3 Sinter and Its Phase Development. DOI: 10.1007/s11663-025-03677-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How are muffle furnaces utilized in dental labs? Essential for Precision Dental Restorations

- What role does the Muffle Furnace play in the pretreatment of K-Mo catalyst precursors? Key for Thermal Oxidation

- What safety features are included in muffle furnaces? Ensure Operator Protection and Lab Safety

- Why is a high-temperature muffle furnace required for the roasting of activated fly ash? Unlock Efficient Phase Changes

- What temperature range can a standard muffle furnace achieve? Find Your Ideal Heat Range

- What critical environmental conditions does a muffle furnace provide for aluminum cast iron? Optimize Your Heat Treatment

- What is the main advantage of a muffle furnace? Ensure Purity and Longevity in High-Temp Processes

- What is the primary function of a high-temperature muffle furnace in ilmenite smelting? Enhance Carbothermic Efficiency