In modern muffle furnaces, safety is a foundational design principle, not an afterthought. These devices are engineered with multiple, often redundant, layers of protection to safely manage the extreme temperatures they generate. Key features include automatic power cutoffs like circuit breakers and door switches, robust physical insulation to keep the exterior cool, and precise digital controllers that prevent dangerous overheating.

The safety of a muffle furnace relies on an integrated system of features. This system works cohesively to contain extreme heat, manage high electrical loads, and isolate the operator from the inherent dangers of high-temperature processes.

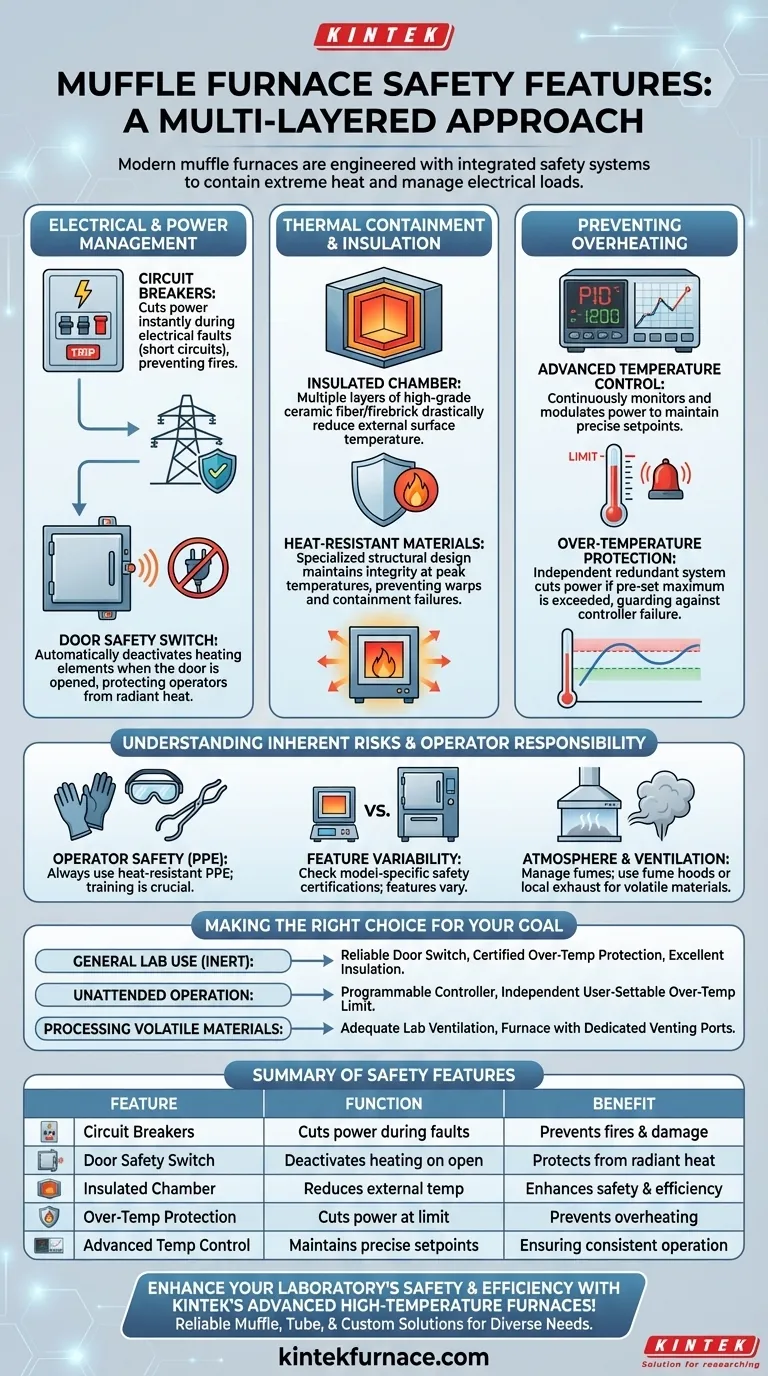

A Multi-Layered Approach to Operator Safety

A muffle furnace's safety is not dependent on a single component. Instead, it is the result of several electrical, thermal, and mechanical systems working in concert to protect the user, the sample, and the lab environment.

Electrical and Power Management

Circuit breakers are the first line of defense against electrical malfunctions. If the furnace draws excessive current due to a short circuit or other fault, the breaker trips, instantly cutting all power to the unit and preventing a potential fire or catastrophic failure.

A door safety switch is a critical active protection feature. This switch automatically cuts power to the heating elements the moment the furnace door is opened. This prevents the operator from being accidentally exposed to the chamber's intense radiant heat, which can reach well over 1000°C.

Thermal Containment and Insulation

The insulated chamber is a dual-purpose feature, crucial for both energy efficiency and safety. Multiple layers of high-grade ceramic fiber or firebrick insulation dramatically reduce the external surface temperature of the furnace, making the unit safer to work around.

Furnaces are built with specialized heat-resistant materials and structural designs. This ensures the unit maintains its integrity at peak operating temperatures, preventing warps or failures that could compromise the containment of heat.

Preventing Overheating and Runaway Temperatures

Modern mrule furnaces use advanced temperature control systems. A primary controller continuously monitors the internal temperature and modulates power to the heating elements to precisely maintain the desired setpoint.

Many furnaces also include a separate over-temperature protection circuit. This is a redundant safety system that will cut power to the furnace if it exceeds a pre-set maximum temperature, guarding against a failure of the primary controller.

Understanding the Inherent Risks

While well-designed furnaces are safe, it's critical to understand their operational risks and limitations. Technology alone cannot replace user diligence.

The Operator is the Final Safety Check

No safety feature can substitute for proper training and personal protective equipment (PPE). Operators must always use heat-resistant gloves, safety glasses, and tongs when loading or unloading a hot furnace.

Feature Variability Between Models

Safety features are not universal across all models. Small, economical benchtop furnaces may have fewer redundancies than large, industrial-grade units. Always verify that a specific model's safety certifications and features are appropriate for your intended application.

Atmosphere and Ventilation are Your Responsibility

A muffle furnace is designed to contain heat, not necessarily process fumes. If you are heating materials that release smoke, toxic gases, or vapors, you must operate the furnace inside a fume hood or have ব্যবস্থা for adequate local exhaust ventilation.

Making the Right Choice for Your Goal

Selecting a furnace requires matching its safety profile to the risk of your work.

- If your primary focus is general lab use with inert materials: Ensure the furnace has a reliable door switch, certified over-temperature protection, and excellent thermal insulation.

- If your primary focus is unattended or overnight operation: Prioritize a furnace with a sophisticated programmable controller and a fully independent, user-settable over-temperature limit controller.

- If your primary focus is processing volatile materials: Your selection criteria must extend beyond the furnace to include your lab's ventilation capacity and the need for a furnace with dedicated venting ports.

Ultimately, understanding these integrated safety systems empowers you to operate the equipment with the confidence and respect it requires.

Summary Table:

| Safety Feature | Function | Benefit |

|---|---|---|

| Circuit Breakers | Cuts power during electrical faults | Prevents fires and equipment damage |

| Door Safety Switch | Deactivates heating when door opens | Protects operators from radiant heat exposure |

| Insulated Chamber | Reduces external surface temperature | Enhances energy efficiency and prevents burns |

| Over-Temperature Protection | Cuts power if temperature exceeds limit | Prevents overheating and sample damage |

| Advanced Temperature Control | Maintains precise setpoints | Ensures consistent and safe operation |

Enhance your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, minimizing risks and maximizing performance. Contact us today to discuss how our tailored furnace solutions can protect your operators and optimize your processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment