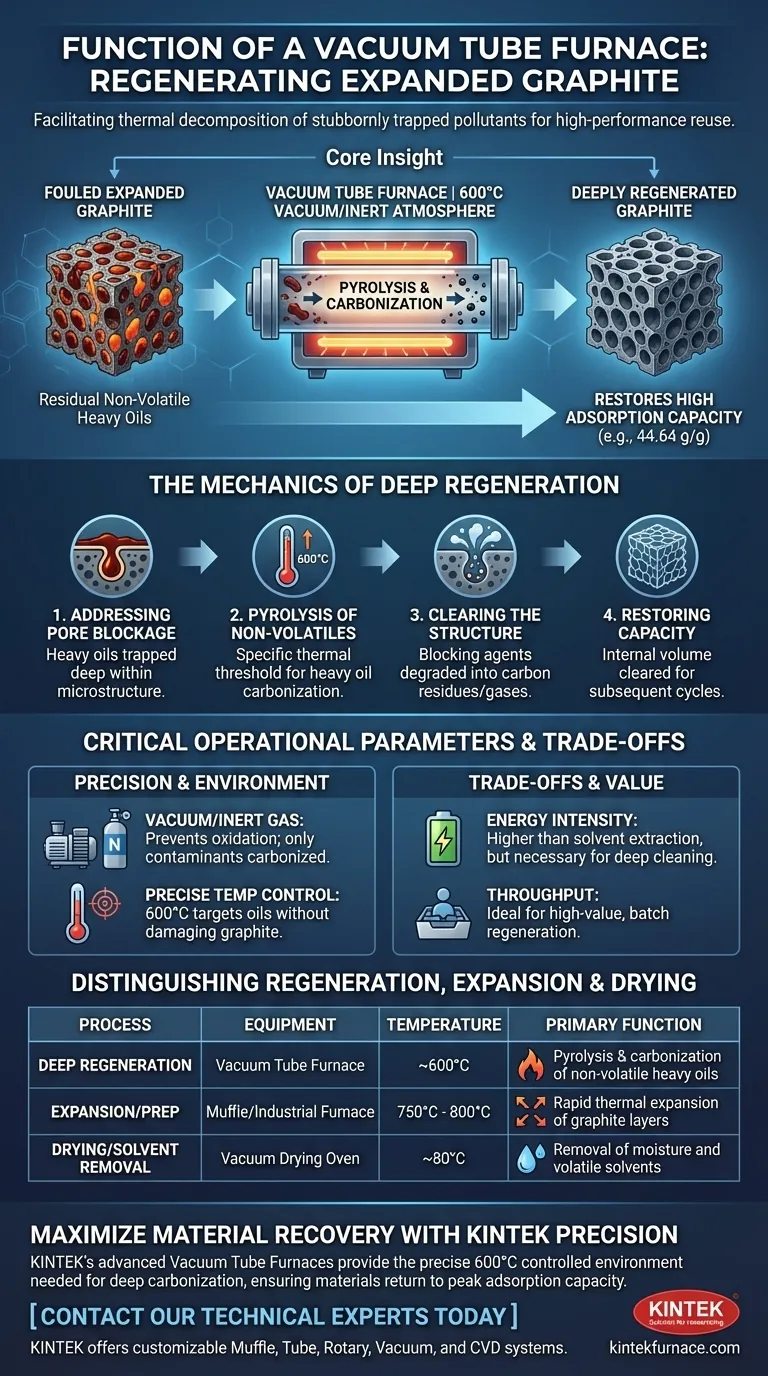

The function of a vacuum tube furnace in the regeneration of expanded graphite is to facilitate the thermal decomposition of stubbornly trapped pollutants. Specifically, it subjects the material to a controlled environment—typically at 600°C under vacuum or a nitrogen atmosphere—to pyrolyze residual non-volatile heavy oils that have clogged the graphite's porous structure.

Core Insight: While simple vacuum distillation removes volatile oils, a vacuum tube furnace is required to chemically break down (carbonize) the heavy, non-volatile residues deep within the pores. This "deep regeneration" clears the internal surface area, effectively restoring the expanded graphite’s high adsorption capacity for reuse.

The Mechanics of Deep Regeneration

Addressing Pore Blockage

Expanded graphite (EG) is a powerful adsorbent, but after multiple cycles, its pores become clogged. While volatile substances can be evaporated, heavy oils often remain trapped deep within the microstructure.

Pyrolysis of Non-Volatiles

The vacuum tube furnace solves this by raising the temperature to approximately 600°C. At this specific thermal threshold, the residual non-volatile heavy oils undergo pyrolysis and carbonization.

Clearing the Structure

This carbonization process effectively degrades the blocking agents into carbon residues or gases. This clears the blocked pores, restoring the internal volume necessary for adsorption.

Restoring Capacity

The result is a "deeply regenerated" material. The process can restore adsorption capacities to high levels, such as 44.64 grams per gram, making the graphite effective for subsequent cycles.

Critical Operational Parameters

The Role of Vacuum and Inert Gas

Standard heating would burn the graphite itself. The furnace operates under vacuum or a nitrogen atmosphere to prevent oxidation. This ensures that only the contaminants are carbonized, while the graphite matrix remains intact.

Precise Temperature Control

Unlike the initial expansion of graphite (which often occurs at 750°C–800°C), regeneration in this context targets 600°C. This temperature is sufficient to degrade heavy oils without subjecting the graphite to unnecessary thermal stress or energy waste.

Distinguishing Regeneration from Preparation

Regeneration vs. Expansion

It is vital to distinguish this process from the preparation of expanded graphite. Preparation typically uses an industrial tube furnace or muffle furnace at higher temperatures (750°C to 800°C) to violently expand the interlayer spacing. The vacuum tube furnace described here is utilized after the material has been used and saturated.

Carbonization vs. Drying

This process is also distinct from simple drying. A vacuum drying oven typically operates at much lower temperatures (e.g., 80°C) to remove solvents like ethanol. The tube furnace operates at much higher temperatures to chemically alter (carbonize) heavy contaminants that cannot be removed by simple evaporation.

Understanding the Trade-offs

Energy Intensity

Running a furnace at 600°C is energy-intensive compared to low-temperature solvent extraction. However, it is often the only way to recover capacity when pores are fouled by heavy, non-volatile compounds.

Throughput Limitations

Tube furnaces are generally batch-processing units or continuous flow units with limited volume compared to massive industrial kilns. This makes them ideal for high-value regeneration where maintaining the precise pore structure is critical.

Making the Right Choice for Your Goal

To select the correct thermal treatment equipment, you must identify the specific stage of the graphite lifecycle you are addressing:

- If your primary focus is deep regeneration of saturated graphite: Use a Vacuum Tube Furnace at 600°C to carbonize residual heavy oils and clear blocked pores.

- If your primary focus is creating expanded graphite (Expansion): Use a Muffle Furnace or Industrial Tube Furnace at 750°C–800°C to shock the material into expanding its volume.

- If your primary focus is removing solvents or moisture: Use a Vacuum Drying Oven at roughly 80°C to preserve surface chemistry without carbonization.

In summary, the vacuum tube furnace is the precise tool required to purge non-volatile contaminants from expanded graphite, bridging the gap between a fouled waste product and a high-performance reusable material.

Summary Table:

| Process Type | Equipment Used | Temperature | Primary Function |

|---|---|---|---|

| Deep Regeneration | Vacuum Tube Furnace | ~600°C | Pyrolysis & carbonization of non-volatile heavy oils |

| Expansion/Prep | Muffle/Industrial Furnace | 750°C - 800°C | Rapid thermal expansion of graphite layers |

| Drying/Solvent Removal | Vacuum Drying Oven | ~80°C | Removal of moisture and volatile solvents (e.g., ethanol) |

| Deep Cleaning | Vacuum Tube Furnace | 600°C (Inert) | Clearing blocked pores to restore adsorption capacity |

Maximize Your Material Recovery with KINTEK Precision

Don't let clogged pores diminish your expanded graphite's performance. KINTEK’s advanced Vacuum Tube Furnaces provide the precise 600°C controlled environment needed for deep carbonization and regeneration, ensuring your materials return to peak adsorption capacity.

Backed by expert R&D and world-class manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific lab or industrial high-temperature requirements. Whether you are expanding, carbonizing, or drying, we have the thermal solution for you.

Ready to optimize your regeneration process? Contact our technical experts today to discuss your custom furnace needs!

Visual Guide

References

- Chun Man Li. Recyclability and Carbonization Regeneration of Oil Adsorbing Materials Based on Commercial Expandable Graphite. DOI: 10.4028/p-r32wge

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are some thermal processes that tube furnaces are used for? Achieve Precise Heat Treatment with Uniformity

- What is the function of a tube reactor during the reduction process of Siderite Ore? Optimize Your Metallization Process

- Which industries commonly use horizontal electric furnaces? Unlock Precision in High-Temperature Processing

- What critical environmental controls does a tubular furnace provide for CMS membranes? Optimize Pore Engineering

- What technical features make a laboratory horizontal tube furnace an ideal reaction device for oil sludge studies?

- What environmental conditions does a tube furnace provide for CFeS aerogels? Master Carbonization & Inert Protection

- What critical environmental conditions does a high-temperature tube furnace provide? Optimize CPOF-4/5 Cross-Linking

- What is the significance of cooling rate control in a high-precision tube furnace for h-ScFeO3? Prove Stability Now