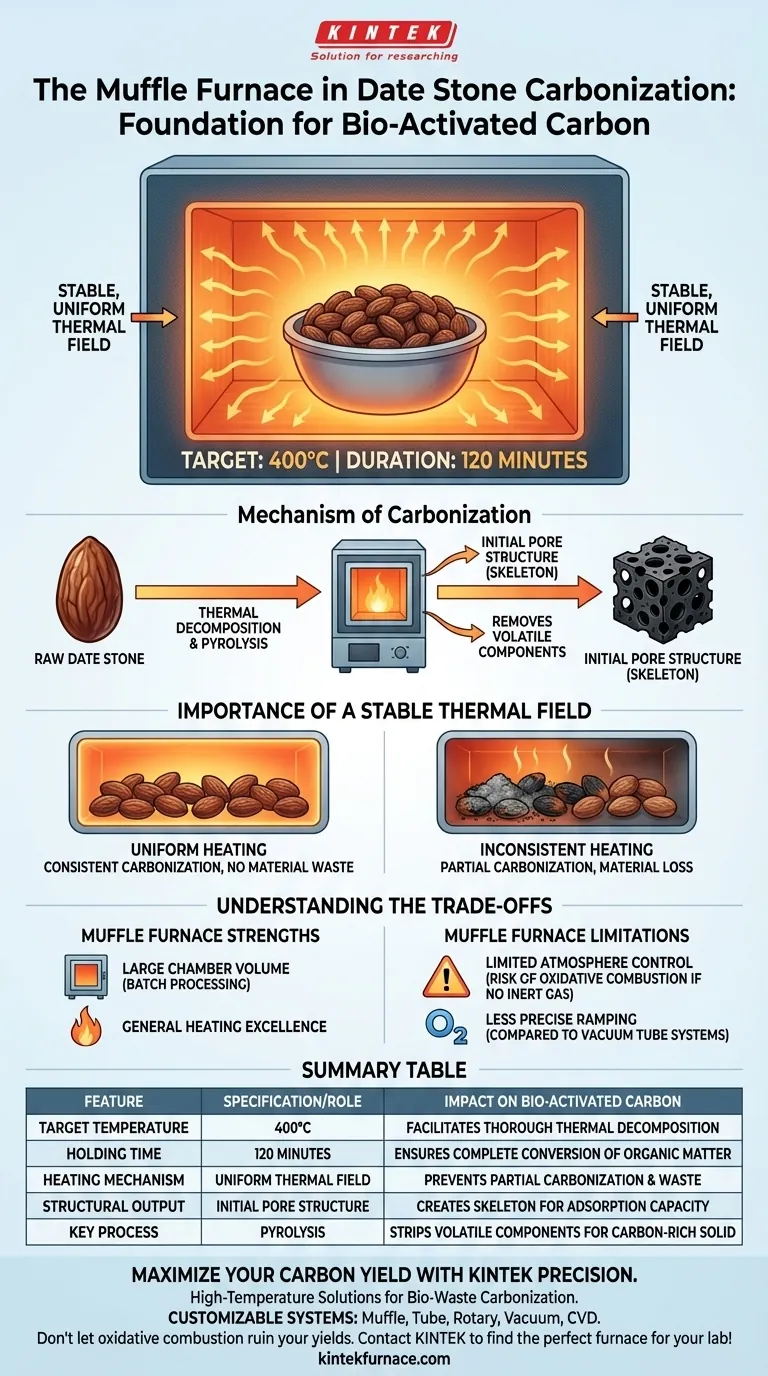

The primary function of a Muffle Furnace during the processing of date stones is to provide a stable, precisely controlled thermal environment for carbonization. Specifically, it subjects the biomass to a consistent temperature of 400°C for 120 minutes, facilitating the thorough thermal decomposition of organic matter into carbon.

Core Takeaway By maintaining a uniform thermal field, the Muffle Furnace drives the pyrolysis process that converts raw date stones into a carbonized material. This step is critical for removing volatile components and establishing the initial pore structure that serves as the foundation for high-quality activated carbon.

The Mechanism of Carbonization

The Muffle Furnace is not merely a heating device; it is the vessel that dictates the physical transformation of the biomass. Its role can be broken down into two specific mechanical functions.

Precise Thermal Decomposition

The furnace operates at a target temperature of 400°C, maintained for a duration of 120 minutes.

During this window, the heat causes the organic compounds within the date stones to break down. This process, known as pyrolysis, strips away non-carbon elements, leaving behind a carbon-rich solid.

Creation of the Initial Pore Structure

The stability of the furnace is essential for the structural integrity of the final product.

As volatile matter is expelled from the date stones, it leaves behind voids. These voids become the initial pore structure. This "skeleton" is the precursor to the highly developed network of micropores and mesopores that will define the material's adsorption capacity later in the process.

The Importance of a Stable Thermal Field

A defining feature of the Muffle Furnace is its ability to create a uniform "thermal field."

Ensuring Uniformity

Inconsistent heating can lead to partial carbonization, where some date stones are burnt to ash while others remain raw.

The Muffle Furnace surrounds the sample with heat, ensuring that every piece of biomass within the chamber undergoes the same degree of thermal decomposition.

Facilitating Chemical Interactions

While the primary reference focuses on heat, supplementary data indicates this environment supports chemical activation.

If chemical agents (like ZnCl2) are present, the stable heat facilitates dehydration and oxidation reactions. This interaction between the chemical agent and the carbon matrix is what ultimately expands the surface area and develops the material's porosity.

Understanding the Trade-offs

While effective, the Muffle Furnace has limitations compared to other equipment like Vacuum Tube Furnaces.

Atmosphere Control Limitations

A standard Muffle Furnace is excellent for general heating, but it may not offer the strict atmosphere control of a tube furnace.

If the chamber is not adequately flushed with an inert gas (like nitrogen), oxygen may remain. This poses a risk of oxidative combustion, where the biomass burns away rather than carbonizing.

Precision vs. Throughput

Muffle furnaces generally offer a larger chamber volume for batch processing compared to narrow tube furnaces.

However, they may lack the rapid, highly precise temperature ramping (e.g., specific gradients per minute) available in high-vacuum systems designed for controlling atomic arrangement and graphitization.

Making the Right Choice for Your Goal

The choice of equipment and parameters defines the quality of your bio-activated carbon.

- If your primary focus is establishing a basic carbon skeleton: Adhere to the standard protocol of 400°C for 120 minutes to ensure complete thermal decomposition without over-burning.

- If your primary focus is maximizing pore development with chemical agents: Ensure the furnace can maintain a stable temperature (up to 500-700°C) to allow activating agents to effectively dehydrate and oxidize the carbon matrix.

- If your primary focus is preventing material loss: Verify that your Muffle Furnace setup includes a nitrogen or inert gas inlet to prevent oxygen from turning your yield into ash.

The Muffle Furnace is the foundational tool that transforms raw date stones from biological waste into a structurally stable carbon scaffold ready for activation.

Summary Table:

| Feature | Specification/Role | Impact on Bio-Activated Carbon |

|---|---|---|

| Target Temperature | 400°C | Facilitates thorough thermal decomposition |

| Holding Time | 120 Minutes | Ensures complete conversion of organic matter |

| Heating Mechanism | Uniform Thermal Field | Prevents partial carbonization and material waste |

| Structural Output | Initial Pore Structure | Creates the "skeleton" for high adsorption capacity |

| Key Process | Pyrolysis | Strips volatile components to leave a carbon-rich solid |

Maximize Your Carbon Yield with KINTEK Precision

Ready to elevate your material research? KINTEK provides industry-leading high-temperature solutions tailored for bio-waste carbonization and chemical activation. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research or production requirements.

Don't let oxidative combustion ruin your yields. Our systems ensure the stable thermal fields and atmosphere control necessary for superior pore development. Contact KINTEK today to find the perfect furnace for your lab!

Visual Guide

References

- Nabil A. Alhemiary. Synthesis of Novel Nanocomposite CaO/AC/ZnO from Biogenic Wastes of Date Palm Seeds from The Najran Region (Saudi Arabia) and Eggshells for Degradation of Methylene Blue. DOI: 10.15379/ijmst.v11i1.3625

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a high-precision resistance furnace ensure T6 solution treatment? Achieve Peak Alloy Strength with KINTEK

- How does a laboratory high-temperature box furnace facilitate the solution treatment of Al-Cu-Mn alloys?

- How are muffle furnaces manufactured? Discover Precision Engineering for Your Lab

- What are the different types of muffle furnaces based on appearance and shape? Choose the Right Furnace for Your Lab

- Why is it important to avoid exceeding the rated temperature of the muffle furnace? Prevent Damage and Ensure Safety

- What are the key features of muffle furnace construction? Discover Precision and Safety in High-Temp Labs

- What are the common uses of muffle furnaces? Essential for Material Analysis, Heat Treatment, and Synthesis

- What role does a high-precision high-temperature box furnace play in the controlled foaming of aluminum? Key Insights