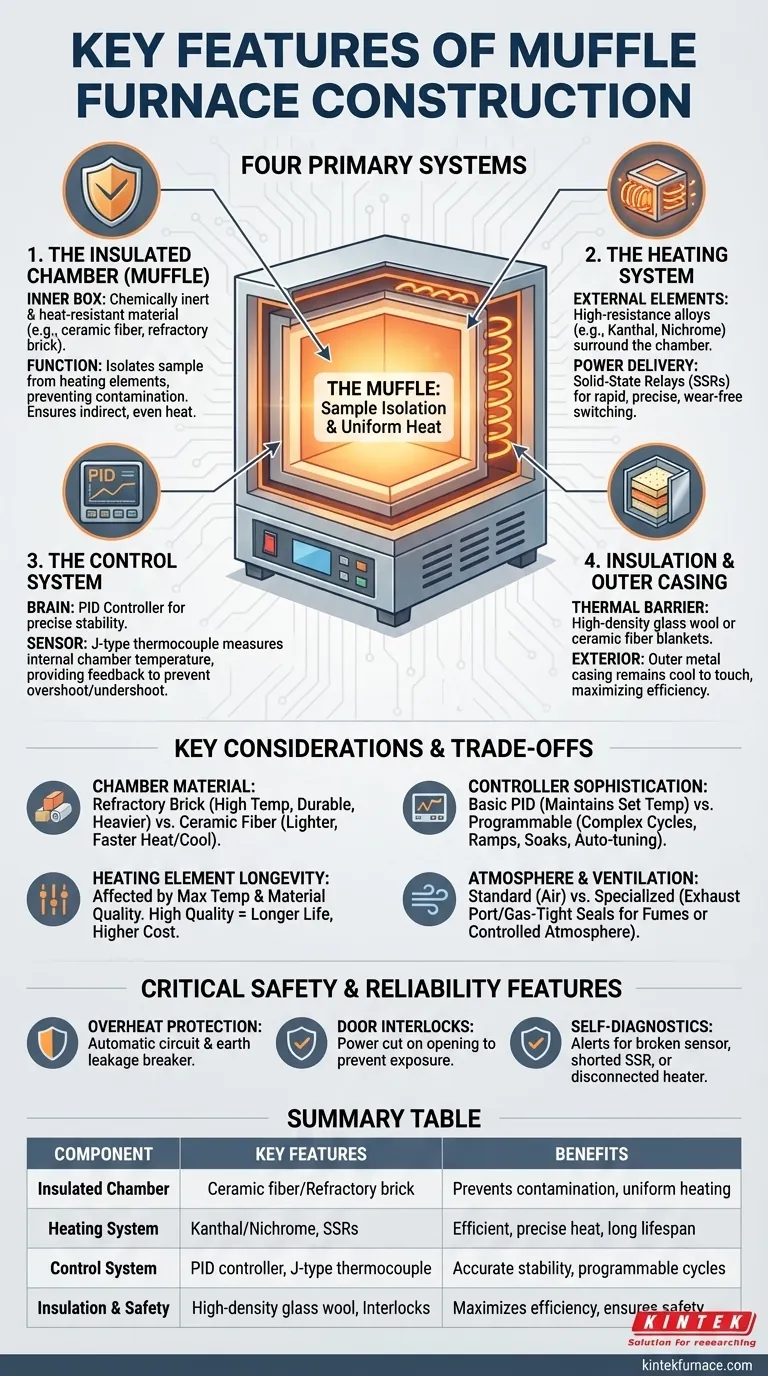

At its core, a muffle furnace is constructed from four primary systems working in concert: an isolated inner chamber, an external heating system, high-grade insulation, and a precise temperature control unit. The "muffle" itself refers to this inner chamber, which is designed to protect the sample from the direct radiation and chemical influence of the heating elements, ensuring both sample purity and uniform temperature distribution.

The fundamental challenge in high-temperature lab work is not just reaching a high temperature, but achieving it uniformly, precisely, and without contaminating the material being tested. A muffle furnace's construction is purpose-built to solve this by physically separating the heat source from the sample chamber.

The Four Pillars of Muffle Furnace Construction

A modern muffle furnace is more than just a hot box. Each component is engineered to contribute to a stable, controlled, and safe heating environment.

1. The Insulated Chamber (The "Muffle")

This is the heart of the furnace. It is an inner box made of a chemically inert and heat-resistant material, such as high-purity ceramic fiber or refractory brick.

Its primary function is to isolate the sample from the heating elements. This prevents any gases or particles from the elements from contaminating the sample and ensures heat is delivered indirectly and evenly.

2. The Heating System

The heating elements are the components that generate the thermal energy. They are typically made from high-resistance alloys like Kanthal or Nichrome.

Crucially, these elements are placed outside the muffle chamber, surrounding it to radiate heat inward. Power is often delivered to them via Solid-State Relays (SSRs), which allow for rapid, precise switching to maintain a stable temperature without the wear of mechanical relays.

3. The Control System

This is the brain of the furnace, responsible for executing heating commands and maintaining temperature stability.

The industry standard is a PID (Proportional-Integral-Derivative) controller. This sophisticated algorithm constantly monitors the temperature via a sensor and adjusts power to the heaters to prevent overshooting or undershooting the target temperature.

Temperature feedback is provided by a sensor, often a J-type thermocouple, which is placed inside the heating chamber to measure the actual temperature experienced by the sample.

4. The Insulation and Outer Casing

To reach and maintain temperatures that can exceed 1200°C, a furnace must be exceptionally well-insulated.

Layers of high-density glass wool or ceramic fiber blankets are packed between the inner heating assembly and the outer metal casing. This insulation maximizes thermal efficiency by preventing heat loss and keeps the exterior of the furnace cool enough to be safe to the touch.

Understanding the Trade-offs and Key Considerations

While the basic design is consistent, the quality and type of components create significant differences in performance and cost.

Insulation and Chamber Material

A furnace with refractory brick insulation will typically be more durable and capable of higher temperatures (up to 1800°C) than one with ceramic fiber. However, it will also be heavier and may heat up and cool down more slowly.

Controller Sophistication

A basic PID controller maintains a set temperature. More advanced controllers offer programmable steps, ramps, and soaks, allowing for complex, automated thermal cycles. Features like auto-tuning help the controller learn the furnace's thermal properties for even greater accuracy.

Heating Element Longevity

Heating elements are consumables with a finite lifespan. Their longevity is affected by the maximum temperature they are run at and the materials they are made from. High-quality elements will last longer but come at a higher initial cost.

Atmosphere and Ventilation

A standard muffle furnace operates in air. If your process releases fumes or requires a specific atmosphere (like nitrogen or argon), you must look for a model with an exhaust port or gas-tight seals and inlet ports. This is a critical feature that is not present on all models.

Critical Safety and Reliability Features

A well-constructed furnace prioritizes safety and operational reliability through several key features.

Overheat and System Protection

An automatic overheat prevention circuit is a non-negotiable safety feature that cuts power if the main controller fails and the temperature rises uncontrollably. An earth leakage breaker protects the user from electrical shock.

Door Interlocks

Nearly all modern furnaces include a door safety switch. This immediately cuts power to the heating elements when the door is opened, preventing exposure to extreme temperatures and electrical hazards.

Self-Diagnostic Functions

Advanced models include self-diagnostics that can alert the user to problems like a broken sensor, a shorted SSR, or a disconnected heater. This prevents failed experiments and simplifies maintenance by identifying the source of a problem.

Making the Right Choice for Your Application

Understanding the construction helps you select the right tool for your specific goal.

- If your primary focus is general lab work like ashing or heat-treating: A standard electric furnace with a reliable PID controller and good temperature uniformity is your best choice.

- If your primary focus is high-purity material processing: Pay close attention to the quality and inertness of the inner muffle chamber to prevent any sample contamination.

- If your primary focus is very high temperatures (above 1200°C) or industrial use: Look for a furnace with a robust refractory brick lining and consider models that may use fuel like natural gas.

- If your primary focus is a process that releases fumes (e.g., binder burnout): A model with an integrated exhaust port or a ventilation system is absolutely essential for operator safety.

By understanding how these core components work together, you can confidently evaluate a furnace's capabilities and ensure it meets the demands of your work.

Summary Table:

| Component | Key Features | Benefits |

|---|---|---|

| Insulated Chamber | Made of ceramic fiber or refractory brick; isolates sample | Prevents contamination, ensures uniform heating |

| Heating System | Uses Kanthal/Nichrome elements; powered by SSRs | Efficient, precise heat generation with long lifespan |

| Control System | PID controller with J-type thermocouple | Accurate temperature stability and programmable cycles |

| Insulation & Safety | High-density glass wool; overheat protection, door interlocks | Maximizes efficiency, ensures user safety |

Ready to enhance your lab's capabilities with a custom muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need precise temperature control, contamination-free processing, or specialized safety features, we can design a furnace tailored to your needs. Contact us today to discuss how we can support your high-temperature applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis