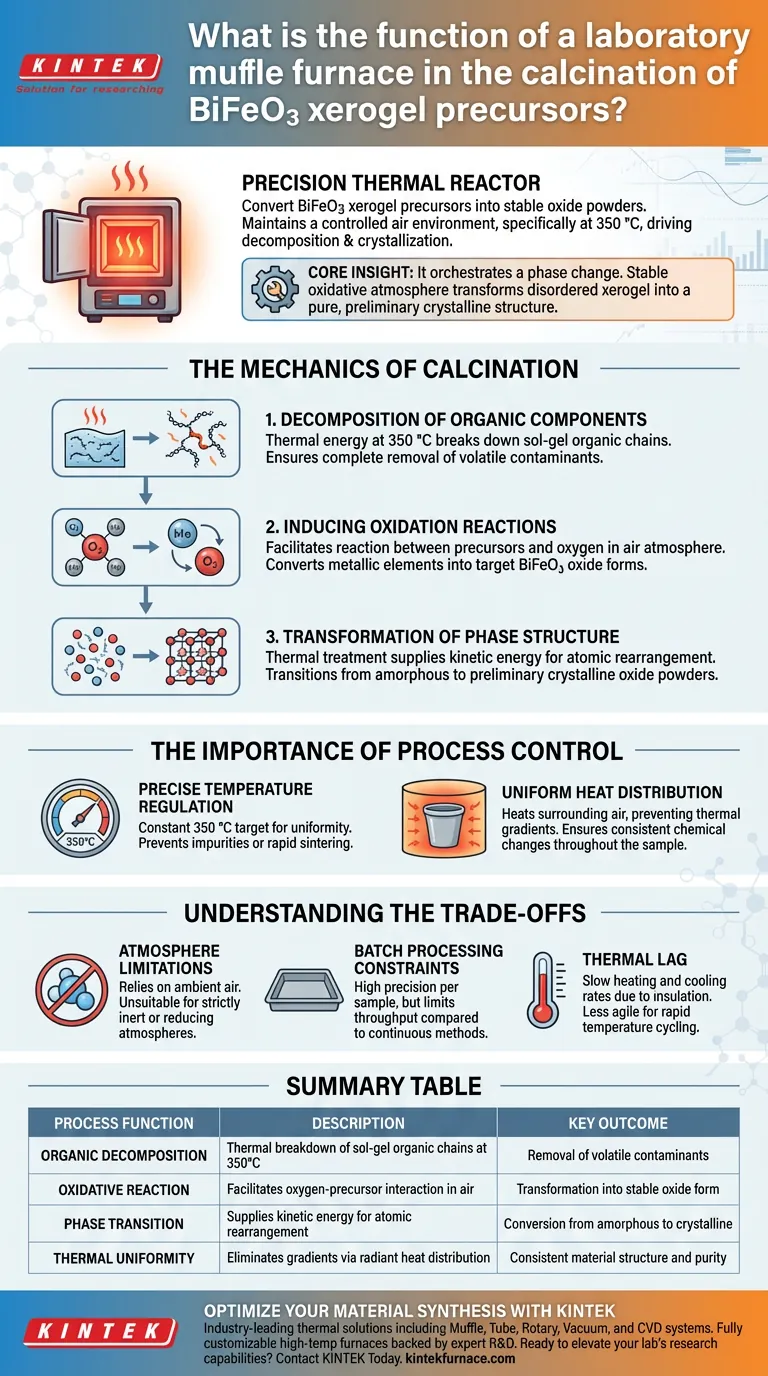

A laboratory muffle furnace acts as a precision thermal reactor designed to convert BiFeO3 xerogel precursors into stable oxide powders. Its primary function is to maintain a controlled air environment at elevated temperatures, specifically around 350 °C, to drive the decomposition of organic residues and initiate the crystallization of the material.

Core Insight: The muffle furnace does not simply heat the material; it orchestrates a phase change. It provides the stable oxidative atmosphere necessary to transform a disordered, organic-rich xerogel into a pure, preliminary crystalline structure.

The Mechanics of Calcination

Decomposition of Organic Components

Xerogel precursors are typically derived from sol-gel processes, meaning they retain a significant amount of organic material. The muffle furnace provides the thermal energy required to break down these organic chains.

By maintaining a steady temperature of 350 °C, the furnace ensures the complete removal of volatile components that would otherwise contaminate the final product.

Inducing Oxidation Reactions

Calcination in a muffle furnace occurs within an air atmosphere, which is chemically active. The furnace facilitates the reaction between the precursor materials and oxygen.

This oxidative environment is essential for converting the metallic elements in the precursor into their target oxide forms (BiFeO3).

Transformation of Phase Structure

The precursor starts as an amorphous (disordered) solid. The thermal treatment provided by the furnace supplies the kinetic energy needed for atoms to rearrange themselves.

This process transitions the material from an amorphous state into preliminary crystalline oxide powders, establishing the fundamental lattice structure required for the material's magnetic and electrical properties.

The Importance of Process Control

Precise Temperature Regulation

Temperature consistency is the defining feature of a muffle furnace. For BiFeO3 xerogels, the specific target of 350 °C must be held constant to ensure uniformity.

Precise regulation prevents temperature spikes that could lead to unwanted phase impurities or rapid sintering, while ensuring the temperature is high enough to fully decompose the organics.

Uniform Heat Distribution

Unlike direct heating methods, a muffle furnace heats the air surrounding the sample. This ensures that the heat penetrates the xerogel powder from all sides.

Uniform heating prevents the formation of a thermal gradient, ensuring that the material at the center of the crucible undergoes the same chemical changes as the material on the surface.

Understanding the Trade-offs

Atmosphere Limitations

While excellent for oxidation, a standard muffle furnace relies on ambient air. If your synthesis requires a strictly inert atmosphere (to prevent oxidation) or a reducing atmosphere, a standard air-filled muffle furnace is unsuitable without specialized modification.

Batch Processing Constraints

Muffle furnaces are typically batch-processing tools. This allows for high precision over a single sample set but limits throughput compared to continuous processing methods used in industrial manufacturing.

Thermal Lag

Due to the insulation required to maintain stability, muffle furnaces can have slow heating and cooling rates. This "thermal lag" means the equipment is less agile if your protocol requires rapid temperature cycling (quenching).

Making the Right Choice for Your Goal

To ensure the success of your calcination process, align your equipment settings with your specific material requirements.

- If your primary focus is Purity: Ensure the furnace is vented properly to allow the byproducts of organic decomposition to escape, preventing re-contamination of the BiFeO3.

- If your primary focus is Crystallinity: Verify the temperature stability of your furnace at 350 °C; fluctuations here can result in mixed amorphous/crystalline phases.

The muffle furnace is the bridge between a chemical precursor and a functional material, providing the stability required to define the material's final physical structure.

Summary Table:

| Process Function | Description | Key Outcome |

|---|---|---|

| Organic Decomposition | Thermal breakdown of sol-gel organic chains at 350°C | Removal of volatile contaminants |

| Oxidative Reaction | Facilitates oxygen-precursor interaction in air | Transformation into stable oxide form |

| Phase Transition | Supplies kinetic energy for atomic rearrangement | Conversion from amorphous to crystalline |

| Thermal Uniformity | Eliminates gradients via radiant heat distribution | Consistent material structure and purity |

Optimize Your Material Synthesis with KINTEK

Precise thermal processing is the foundation of high-quality BiFeO3 production. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all meticulously engineered for the demanding needs of modern laboratories.

Backed by expert R&D and precision manufacturing, our high-temp furnaces are fully customizable to meet your unique calcination and sintering requirements. Whether you are focusing on high purity or specific crystallinity, we offer the technical support and equipment reliability you need to succeed.

Ready to elevate your lab’s research capabilities? Contact KINTEK Today to Consult with Our Specialists

Visual Guide

References

- Anders Brennhagen, Helmer Fjellvåg. Unraveling the (De)sodiation Mechanisms of BiFeO<sub>3</sub> at a High Rate with <i>Operando</i> XRD. DOI: 10.1021/acsami.3c17296

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the power requirements for the muffle furnace? Ensure Safe and Efficient Operation

- What is a muffle furnace and where is it commonly used? Essential for High-Temperature, Contamination-Free Heating

- What safety features are incorporated in muffle furnaces? Ensure Operator Protection and Equipment Safety

- How does a muffle furnace facilitate the final conversion of ZnO nanopowders? Precision Calcination for Pure Results

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- Why are box type electric furnaces indispensable in industry and laboratories? Unlock Precision and Versatility in Thermal Processing

- How does muffle furnace calcination at 900°C for 13 hours form P2-type cathode structures?

- How is a laboratory box furnace utilized in the production of nanomaterials? Mastering Hydrothermal Synthesis