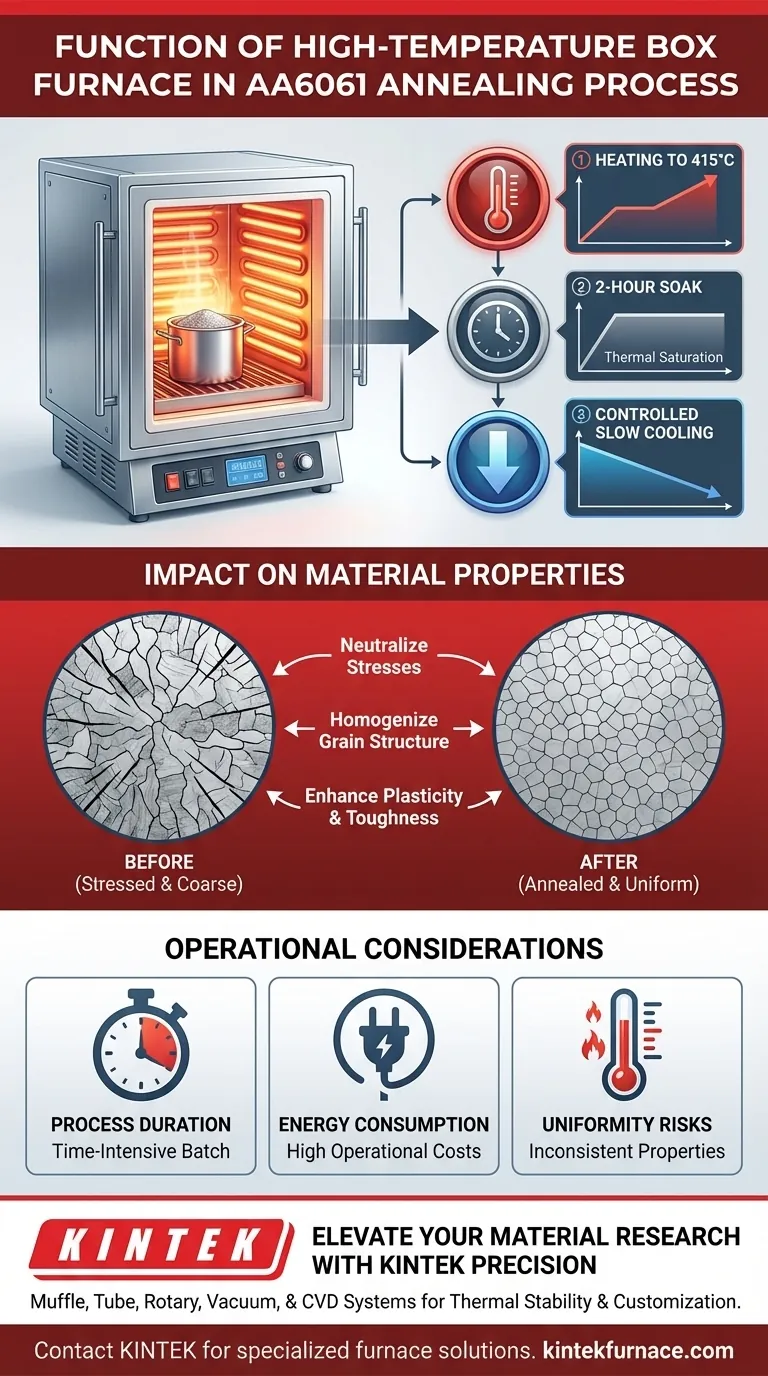

A high-temperature box furnace acts as a precision thermal chamber designed to fundamentally alter the microstructure of AA6061 aluminum alloy. Its specific function in this context is to execute a rigorous three-step thermal cycle: heating the material to exactly 415°C, maintaining this temperature for two hours, and facilitating a controlled slow cooling phase.

By stabilizing the thermal environment, the furnace removes internal manufacturing stresses and reconfigures the grain structure. This process is critical for creating a standardized material baseline, ensuring accurate data when observing complex phenomena like the electroplastic effect in later experiments.

The Mechanics of Thermal Treatment

Reaching the Critical Temperature

The furnace must reliably raise the AA6061 alloy to 415°C. This specific temperature threshold is required to initiate the necessary microstructural changes without melting or damaging the alloy.

The Two-Hour Soak

Once the target temperature is reached, the furnace maintains thermal equilibrium for a duration of two hours. This "holding" or "soaking" period allows heat to penetrate the material fully, ensuring the core reaches the same temperature as the surface.

Controlled Slow Cooling

Unlike quenching, which hardens material, the box furnace facilitates a slow cooling process. This gradual reduction in temperature is what permanently locks in the softer, more ductile state required for annealing.

Impact on Material Properties

Eliminating Residual Stresses

Prior to annealing, the alloy often contains internal forces left over from casting, forging, or cutting. The furnace's thermal cycle relaxes the atomic structure, effectively neutralizing these residual stresses.

Adjusting Grain Structure

The heat treatment promotes the reorganization of the metal's crystalline structure. This results in a more homogeneous grain distribution, which is essential for consistent mechanical behavior across the entire workpiece.

Enhancing Plasticity

By reducing hardness, the furnace significantly improves the material's plasticity and toughness. This makes the alloy softer and more pliable, preparing it for subsequent mechanical deformation processes.

Operational Trade-offs and Considerations

Process Duration

Annealing AA6061 is not a rapid fix. The requirement for a slow ramp-up, a two-hour hold, and a gradual cool-down makes this a time-intensive batch process that can create bottlenecks in production.

Energy Consumption

Maintaing a large chamber at 415°C requires significant energy input. Inefficient furnace insulation or loading practices can lead to high operational costs relative to the volume of material treated.

Temperature Uniformity Risks

If the box furnace fails to circulate heat evenly, "cold spots" may occur. This leads to inconsistent mechanical properties within a single batch, rendering the material unsuitable for precision testing like hydraulic bulging.

Ensuring Process Success

To achieve the best results when annealing AA6061, you must align the furnace capabilities with your specific end goals.

- If your primary focus is stress relief: Ensure the two-hour holding time is strictly observed to allow full thermal saturation of the workpiece.

- If your primary focus is experimental accuracy: Prioritize furnace temperature stability to guarantee the uniform properties needed for observing the electroplastic effect.

- If your primary focus is forming capability: Monitor the cooling rate closely, as cooling too quickly will negate the softening effects of the anneal.

The high-temperature box furnace is the gatekeeper of material consistency, transforming raw alloy into a reliable substrate for advanced engineering and experimentation.

Summary Table:

| Annealing Stage | Temperature/Duration | Function & Impact |

|---|---|---|

| Heating Phase | Reach 415°C | Initiates microstructural changes safely |

| Soaking Period | 2 Hours Holding | Ensures thermal saturation and core uniformity |

| Cooling Phase | Controlled Slow Cooling | Enhances plasticity and locks in ductile state |

| Final Result | Ambient Temperature | Neutralizes stresses and homogenizes grain structure |

Elevate Your Material Research with KINTEK Precision

Precision is non-negotiable when annealing high-performance alloys like AA6061. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed to deliver the thermal stability your laboratory demands. Backed by expert R&D and advanced manufacturing, our high-temperature furnaces are fully customizable to meet your unique experimental or production needs.

Ready to achieve superior material consistency? Contact KINTEK today to discuss how our specialized furnace solutions can optimize your annealing workflows.

Visual Guide

References

- A. Farkhondeh, Mohammad Javad Mirnia. Experimental Investigation of Electroplastic Effect on Ductile Fracture Phenomenon of Annealed AA6061 Aluminum Alloy in Different Stress States through Hydraulic Bulge Test. DOI: 10.5829/ije.2026.39.06c.09

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is a box type resistance furnace and how does it work? Discover Its Key Components and Benefits

- What are the typical uses of muffle furnaces in laboratory settings? Unlock Precise Heat Treatment for Your Lab

- What types of materials are commonly processed in muffle furnaces? Unlock High-Temp Precision for Metals, Ceramics, and More

- What material properties can be achieved using a box furnace? Unlock Enhanced Hardness, Strength, and More

- What temperature range can a standard muffle furnace achieve? Find Your Ideal Heat Range

- What materials can crucible furnaces melt? A Guide to Metals, Glass & Advanced Materials

- What role does a muffle furnace play in the calcination of natural zeolite? Optimize Your Adsorption Studies Today

- Why use a high-temp lab furnace for nanoparticle pre-treatment? Ensure flaw-free composite fabrication today.