In essence, a box type resistance furnace is a high-temperature oven that converts electrical energy into heat. It uses specialized heating elements to achieve precise temperatures within a well-insulated chamber, making it a foundational tool for laboratories, research institutes, and industrial settings.

A box type resistance furnace is more than just a heating device; it's a controlled environment. Its core value lies in its simple, reliable design that delivers uniform high temperatures for critical processes like material sintering, analysis, and heat treatment.

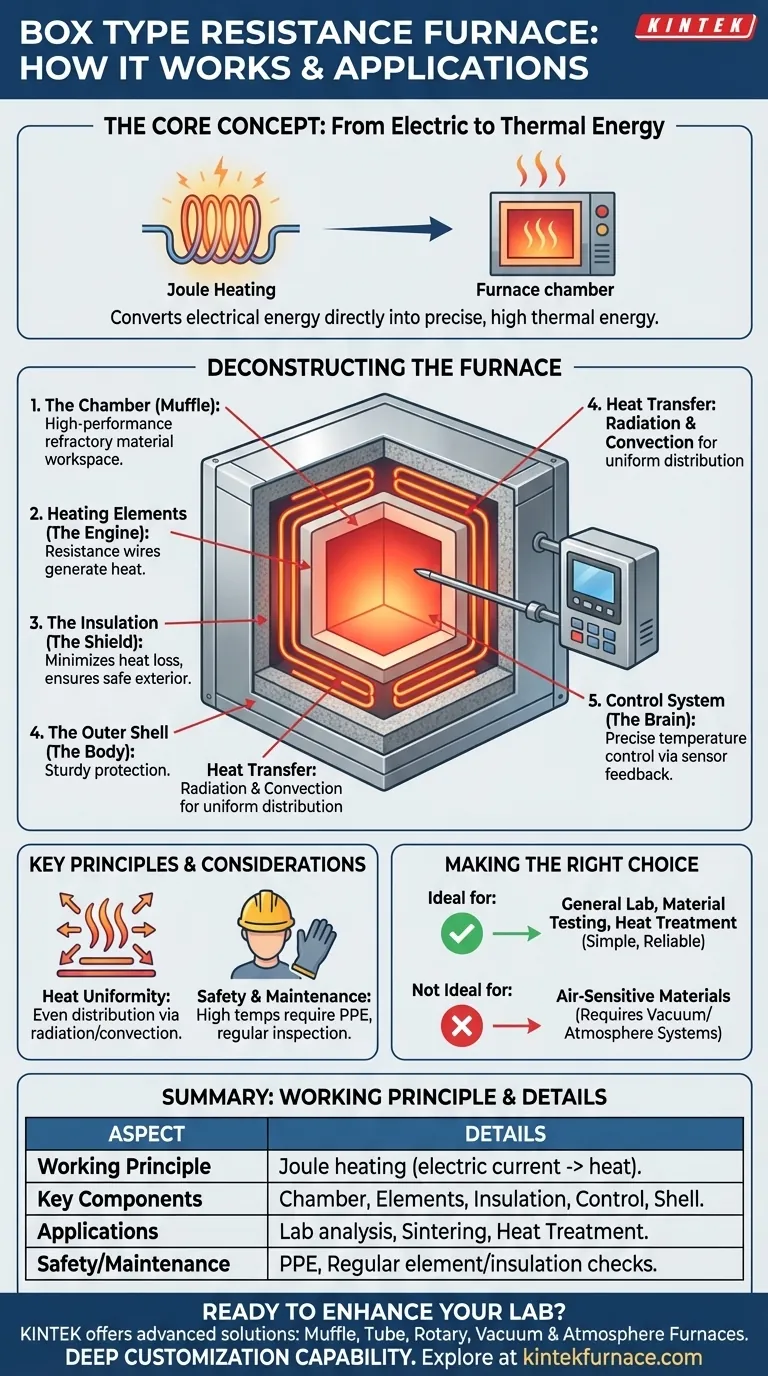

How a Resistance Furnace Generates Heat

The operation of a box furnace is based on a straightforward yet powerful physics principle. It's a closed system designed to generate, contain, and control intense heat with high precision.

The Principle of Resistance Heating

The furnace works on the principle of Joule heating. When an electric current is passed through a material with high electrical resistance, the electrical energy is converted directly into thermal energy, or heat.

This is the same fundamental principle that makes the coils on an electric stove or the filament in an incandescent light bulb glow hot.

The Role of Heating Elements

Inside the furnace chamber, resistance wires or other electric heating elements are strategically placed. These components are made from materials designed to withstand extreme temperatures while providing consistent electrical resistance.

When activated, these elements heat up significantly, becoming the primary source of thermal energy for the entire furnace.

Heat Transfer and Uniformity

The heat generated by the elements is transferred to the materials inside the chamber primarily through thermal radiation and convection. The insulated, box-shaped design ensures this heat is distributed evenly, leading to high temperature uniformity throughout the chamber.

Deconstructing the Box Furnace: Key Components

A box furnace, sometimes called a muffle furnace, is composed of several critical parts working in unison. Understanding each component reveals how it achieves its function.

The Furnace Chamber (The Core)

At the center is the furnace chamber, or "muffle," constructed from high-performance refractory materials like alumina ceramic. This is the workspace where materials are placed for heating.

The Heating Elements (The Engine)

The resistance wires are typically installed along the inner walls of the chamber. Their careful placement is essential for ensuring that every part of the chamber receives uniform heat.

The Insulation Layer (The Shield)

Between the inner furnace chamber and the outer shell lies a thick layer of insulation, often made of aluminum oxide fiber. This material is crucial for two reasons: it minimizes heat loss to maintain high temperatures efficiently and keeps the exterior of the furnace cool enough to be safe.

The Control System (The Brain)

An advanced temperature control system is the furnace's brain. It consists of a temperature sensor (like a thermocouple) inside the chamber and a controller that reads the sensor's data. The controller turns the heating elements on and off to precisely maintain the user-defined temperature setpoint.

The Outer Shell (The Body)

The entire assembly is housed within a sturdy metal shell. This provides structural integrity, protects the internal components, and often includes a door for access and a port or chimney for venting fumes.

Understanding the Trade-offs and Safety

While versatile and reliable, the simplicity of a standard box furnace comes with specific considerations and limitations.

Simplicity vs. Advanced Processes

The primary advantage of a box furnace is its simple, robust design. However, this means standard models are not equipped for processes requiring a controlled atmosphere (e.g., argon or nitrogen) or a vacuum without significant modification.

Operational Safety is Paramount

These furnaces operate at extremely high temperatures. Users must adhere strictly to the manufacturer's safety protocols, use appropriate personal protective equipment (PPE), and be aware of burn risks.

Maintenance for Longevity

To ensure continued performance and safety, regular inspection of heating elements, insulation, and door seals is necessary. Over time, heating elements can degrade and will need to be replaced.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on your specific application.

- If your primary focus is general-purpose lab work, material testing, or small-batch heat treatments: The simplicity, reliability, and excellent temperature uniformity of a box resistance furnace make it an ideal choice.

- If your primary focus is high-volume industrial production: A standard box furnace is excellent for prototyping, but you will likely require larger, automated, or continuous furnace systems for full-scale production.

- If your primary focus is processing air-sensitive materials: A standard box furnace is not suitable; you must use a specialized vacuum furnace or a tube furnace designed for controlled atmospheres.

By understanding its core components and operational principles, you can effectively leverage this fundamental tool with precision and safety.

Summary Table:

| Aspect | Details |

|---|---|

| Working Principle | Joule heating: electric current through high-resistance elements generates heat. |

| Key Components | Chamber (refractory materials), heating elements, insulation, control system, outer shell. |

| Heat Transfer | Thermal radiation and convection for uniform temperature distribution. |

| Applications | Material sintering, heat treatment, analysis in labs, research, and industrial settings. |

| Safety & Maintenance | Requires PPE, regular inspection of elements and insulation; elements may need replacement over time. |

Ready to enhance your lab's capabilities with a reliable high-temperature furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our furnaces can optimize your processes and deliver superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety