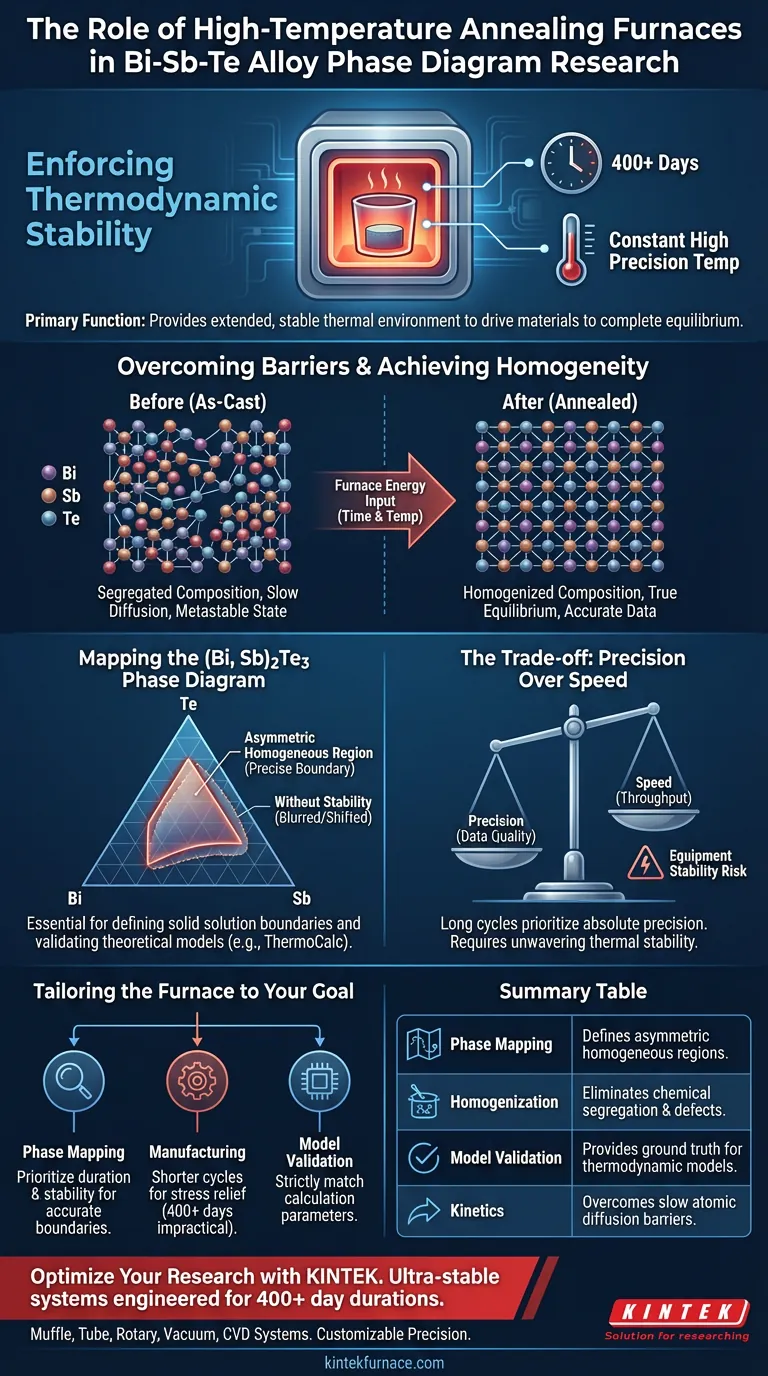

The primary function of a high-temperature annealing furnace in this context is to enforce thermodynamic stability. Specifically for Bismuth-Antimony-Tellurium alloys, the furnace provides a high-precision constant temperature environment for extremely extended periods, sometimes exceeding 400 days. This duration is necessary to drive the material to complete thermodynamic equilibrium.

Core Insight In phase diagram research, time is just as critical as temperature. The annealing furnace facilitates the slow, atomic-level diffusion required to homogenize the chemical composition of the alloy, allowing researchers to accurately define the asymmetric homogeneous regions of (Bi, Sb)2Te3 solid solutions.

The Necessity of Long-Cycle Heat Treatment

Overcoming Kinetic Barriers

In complex alloy systems like Bismuth-Antimony-Tellurium, atoms do not instantly arrange themselves into their most stable configuration. The atomic diffusion rates can be slow. The furnace overcomes these kinetic barriers by maintaining energy input over vast spans of time.

Achieving True Equilibrium

Standard heat treatments are often too short for phase diagram research. To map a phase diagram accurately, the sample must be in a state of complete thermodynamic equilibrium. As noted in the primary reference, this specific alloy system may require heat treatment cycles exceeding 400 days to ensure the internal structure is truly stable and not stuck in a metastable state.

Eliminating Segregation

When alloys are first cast, their chemical composition is rarely uniform. This phenomenon, known as segregation, creates inconsistent data points. The constant high temperature provided by the furnace allows elements to diffuse thoroughly, homogenizing the composition across the entire sample.

Defining the (Bi, Sb)2Te3 Solid Solutions

Mapping Asymmetric Homogeneous Regions

A primary goal of this research is to define the specific boundaries of the solid solution phases. The primary reference highlights the need to define asymmetric homogeneous regions of (Bi, Sb)2Te3. Without the extreme stability provided by the furnace, the boundaries of these regions would appear shifted or blurred, leading to inaccurate scientific models.

Validating Theoretical Models

Experimental data derived from these furnace treatments serves as the "ground truth." By achieving a microstructure close to equilibrium, researchers provide reliable samples to validate thermodynamic calculation models (such as ThermoCalc). This ensures that theoretical predictions align with physical reality.

Understanding the Trade-offs

The Risk of Equipment Instability

The greatest challenge in this process is maintaining equipment reliability. Running a furnace for 400+ days requires an uninterrupted power supply and unwavering thermal stability. Any fluctuation or failure during this long cycle can compromise the equilibrium state, rendering months of waiting useless.

Time vs. Throughput

This process represents a massive bottleneck in research throughput. Dedicating equipment to a single sample for over a year limits the number of experiments a laboratory can run simultaneously. It is a trade-off where data precision is prioritized absolutely over speed.

Making the Right Choice for Your Goal

If your primary focus is Phase Diagram Construction:

- Prioritize thermal stability and duration above all else; the sample must reach complete equilibrium to define phase boundaries accurately.

If your primary focus is Material Manufacturing:

- Focus on shorter annealing cycles sufficient for stress relief and mechanical softening, as 400-day cycles are impractical for production.

If your primary focus is Model Validation:

- Ensure the furnace conditions (vacuum/temperature) strictly match the parameters assumed in your thermodynamic calculations to prevent data discrepancies.

The high-temperature annealing furnace effectively acts as a time machine, accelerating atomic diffusion to reveal the true, stable nature of the alloy.

Summary Table:

| Research Objective | Furnace Function | Outcome for Bi-Sb-Te |

|---|---|---|

| Phase Mapping | Long-cycle thermal stability | Defines asymmetric homogeneous regions |

| Homogenization | Constant atomic diffusion | Eliminates chemical segregation and defects |

| Model Validation | Thermodynamic equilibrium | Provides ground truth for ThermoCalc models |

| Kinetics | Persistent energy input | Overcomes slow atomic diffusion barriers |

Optimize Your Phase Research with KINTEK

Precision is non-negotiable when mapping complex alloys like Bismuth-Antimony-Tellurium. KINTEK provides the ultra-stable thermal environments required for long-cycle thermodynamic research, ensuring your materials reach true equilibrium.

Why Choose KINTEK?

- Expert R&D: Advanced systems engineered for durations exceeding 400 days.

- Versatile Solutions: Our range includes Muffle, Tube, Rotary, Vacuum, and CVD systems.

- Customizable Precision: Tailored high-temp furnaces to meet your specific research or manufacturing parameters.

Contact us today to discuss your unique laboratory needs.

Visual Guide

References

- Hung‐Wei Chen, Hsin‐Jay Wu. Dilute Sb Doping Yields Softer <i>p</i>‐Type Bi<sub>2</sub>Te<sub>3</sub> Thermoelectrics. DOI: 10.1002/aelm.202300793

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are some industrial applications of vacuum furnaces? Unlock Superior Material Performance

- Why is a Spark Plasma Sintering (SPS) system superior to traditional furnaces? Speed and Density for Ceramics

- How does an ultra-high vacuum baking furnace facilitate mid-temperature baking for Niobium cavities? | KINTEK

- What temperature range can vacuum furnaces achieve? Unlock High-Temp Precision for Your Lab

- What safety features are included in the vacuum furnace system? Essential Protection for Your Lab and Materials

- Why is a short working distance essential for miniature vacuum furnaces? Expert Insights for Clear Nanoscale Imaging

- Why is an industrial vacuum oven required for the post-processing of electrode materials? Ensure Battery Performance

- How do the structural features of a box furnace and a vacuum furnace differ? Compare for Your Lab's Needs