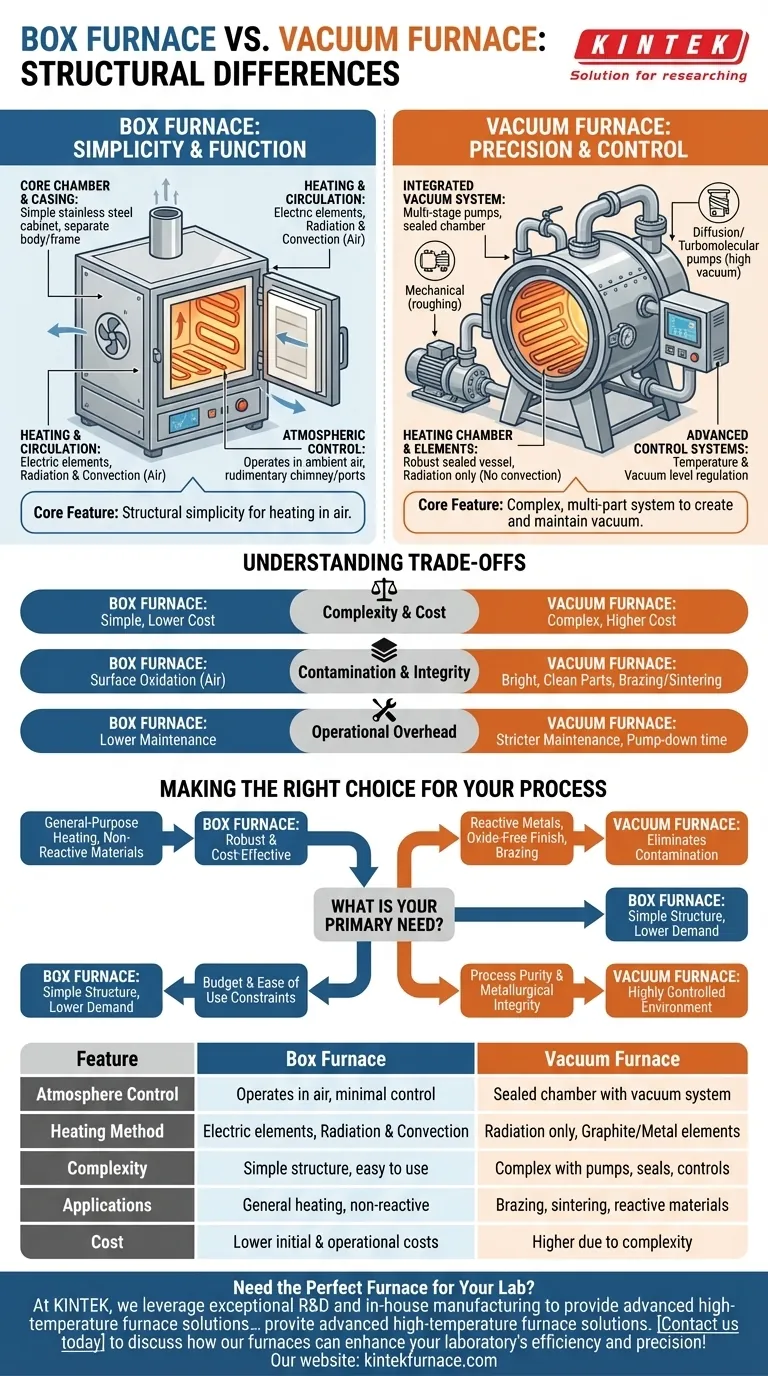

At their core, a box furnace is defined by its structural simplicity for heating in air, while a vacuum furnace is a complex, multi-part system defined by its ability to create a vacuum. The fundamental structural difference is the presence of an integrated vacuum system—including pumps and a sealed chamber—which is the central design feature of a vacuum furnace and entirely absent in a standard box furnace.

The choice between these furnaces is not merely about heating; it is about controlling the processing environment. A box furnace's simple structure is designed to control temperature within an air atmosphere, while a vacuum furnace's complex structure is designed to control temperature and the near-total absence of that atmosphere.

Deconstructing the Box Furnace: Simplicity and Function

A box furnace, often called a muffle furnace, is engineered for straightforward, high-temperature applications where interaction with the atmosphere is acceptable or desired. Its structure prioritizes ease of use and cost-effectiveness.

The Core Chamber and Casing

The furnace consists of a simple, box-shaped cabinet or chamber, typically constructed from stainless steel plates and high-temperature heat-resistant insulation.

For ease of operation and maintenance, the main furnace body and its supporting frame are often built as separate units.

The Heating and Circulation System

Heating is usually accomplished with electric heating wire or similar resistance elements. These elements heat the chamber, and the heat is transferred to the workpiece through both radiation and convection.

To improve temperature uniformity, many box furnaces include auxiliary equipment like fans to circulate the hot air within the chamber.

Atmospheric Control

By default, a box furnace operates in ambient air. Some models offer rudimentary atmospheric control, such as a controllable chimney to vent fumes or ports for introducing specific gases, but they are not designed to hold a vacuum.

Anatomy of a Vacuum Furnace: Precision and Control

A vacuum furnace's structure is inherently more complex because its primary goal is to remove the processing environment (air and other gases) before and during heating.

The Integrated Vacuum System

This is the defining structural feature. It is a multi-stage system comprising a sealed furnace chamber and a series of pumps.

Mechanical pumps are used for initial roughing, while diffusion pumps or turbomolecular pumps are used to achieve the high vacuum levels required for sensitive processes.

The Heating Chamber and Elements

The heating chamber is a robust, sealed vessel capable of withstanding both high temperatures and extreme pressure differences.

Heating elements are made from materials like graphite, ceramic, or refractory metals that perform well in a vacuum. Because a vacuum has very few molecules, heat transfer occurs almost exclusively through radiation, not convection.

The Advanced Control Systems

Vacuum furnaces integrate multiple control systems. An intelligent controller manages the temperature profile, while a separate system monitors and regulates the vacuum level within the chamber, coordinating the operation of the various pumps.

Understanding the Trade-offs

The structural differences create a clear division in capability, complexity, and cost. Understanding these trade-offs is crucial for making an informed decision.

Complexity and Cost

The addition of a vacuum system, a reinforced chamber, and advanced controls makes a vacuum furnace significantly more complex and expensive to build and purchase than a box furnace.

Contamination and Material Integrity

A box furnace will cause oxidation on the surface of most metals due to heating in air. A vacuum furnace’s structure is specifically designed to prevent this, resulting in bright, clean parts and enabling processes like brazing, sintering, and annealing of reactive materials.

Operational Overhead

Operating a vacuum furnace requires more training and a stricter maintenance schedule. The vacuum pumps and seals need regular attention to ensure performance and prevent costly failures. The pump-down cycle also adds time to each process run.

Making the Right Choice for Your Process

Your application's sensitivity to atmospheric contamination is the single most important factor when choosing between these two furnace types.

- If your primary focus is general-purpose heating or simple heat treatments on non-reactive materials: A box furnace offers a robust, cost-effective, and straightforward solution.

- If you are processing reactive metals, require an oxide-free surface finish, or are performing brazing: The vacuum furnace is essential, as its structure is purpose-built to eliminate atmospheric contamination.

- If budget and ease of use are your main constraints: The simpler structure and lower operational demands of a box furnace make it the clear choice.

- If process purity and metallurgical integrity are non-negotiable: The complex but highly controlled environment provided by the vacuum furnace's structure is the only viable option.

Understanding that the structure of each furnace directly enables its function empowers you to select the right tool for your required material outcome.

Summary Table:

| Feature | Box Furnace | Vacuum Furnace |

|---|---|---|

| Atmosphere Control | Operates in air, minimal control | Sealed chamber with vacuum system for no atmosphere |

| Heating Method | Electric elements, radiation and convection | Radiation only, elements like graphite or metals |

| Complexity | Simple structure, easy to use | Complex with pumps, seals, and advanced controls |

| Applications | General heating, non-reactive materials | Brazing, sintering, reactive materials, oxide-free finishes |

| Cost | Lower initial and operational costs | Higher due to complexity and maintenance |

Need the Perfect Furnace for Your Lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're processing reactive materials or require cost-effective heating, we can help you achieve superior results. Contact us today to discuss how our furnaces can enhance your laboratory's efficiency and precision!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures