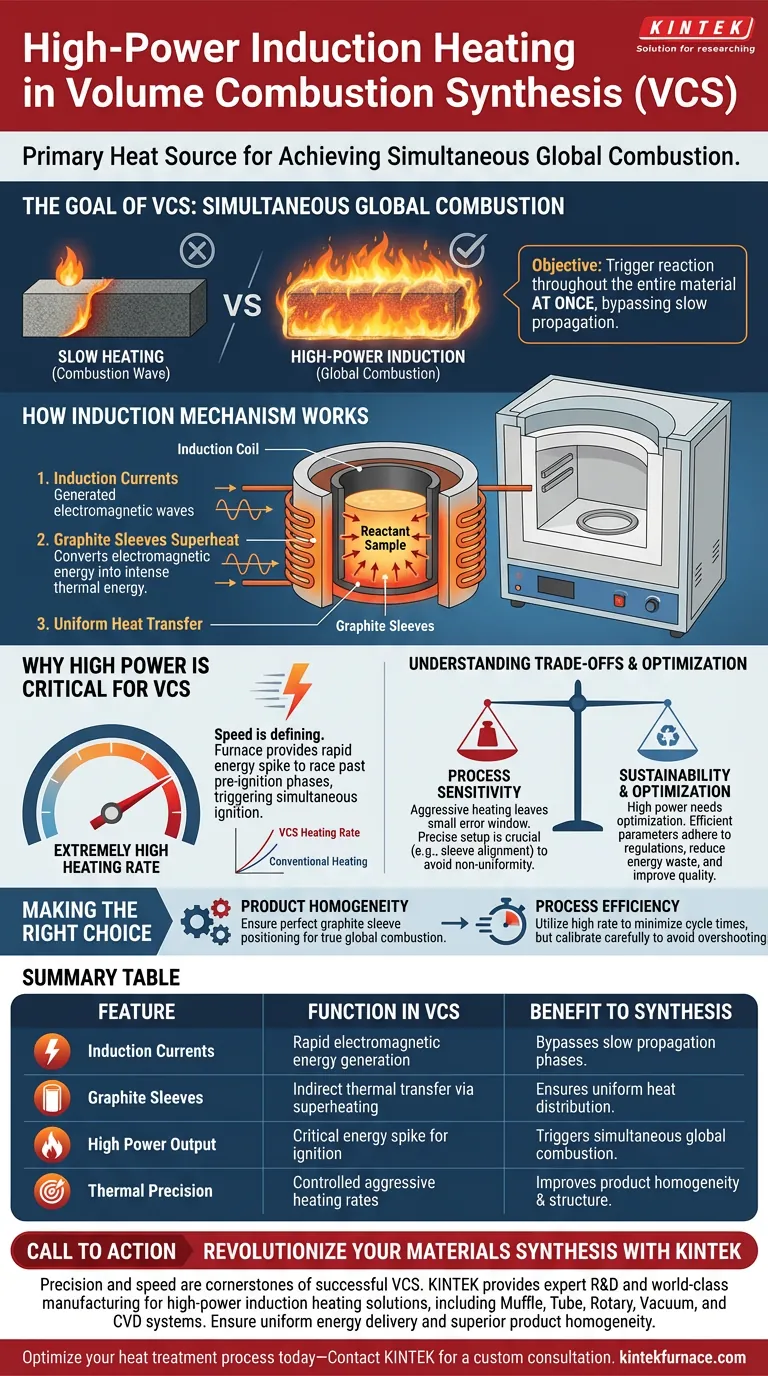

The function of a high-power laboratory induction heating furnace in Volume Combustion Synthesis (VCS) is to act as the primary, high-intensity heat source that drives the synthesis reaction. By utilizing induction currents to rapidly superheat graphite sleeves within a crucible, the furnace transfers thermal energy uniformly to the reactant sample. This equipment is critical because it provides the extreme heating rate necessary to bring the entire reactant mass to its ignition point almost instantly.

In VCS, the objective is to trigger a reaction throughout the entire material at once, rather than letting it burn slowly from one end to the other. The high-power induction furnace provides the rapid energy spike required to bypass slow propagation and achieve simultaneous, global volume combustion.

How the Induction Mechanism Works

Generating Heat via Induction Currents

Unlike conventional ovens that rely on convection or radiation from resistive elements, this furnace utilizes induction currents.

These currents are generated electromagnetically and are directed at specific conductive components within the furnace setup.

The Role of Graphite Sleeves

The induction currents do not necessarily heat the sample directly; rather, they target graphite sleeves located within the crucible.

These sleeves absorb the electromagnetic energy and convert it into intense heat.

Once heated, the sleeves transfer this thermal energy uniformly to the reactant sample, ensuring the material is heated evenly from all directions.

Why High Power is Critical for VCS

Achieving an Extremely High Heating Rate

The defining characteristic of Volume Combustion Synthesis is speed.

The furnace must provide a heating rate high enough to race past the material's pre-ignition phases.

If the heating is too slow, the material may ignite locally, resulting in a combustion wave rather than volume combustion.

Triggering Global Volume Combustion

The ultimate goal of using this specific furnace is to cause the entire reactant mass to reach its ignition point simultaneously.

When this threshold is crossed rapidly and uniformly, the reaction occurs throughout the entire volume at the same time.

This results in efficient synthesis and a more homogeneous final product structure.

Understanding the Trade-offs

Process Sensitivity

Because the heating rate is so aggressive, the window for error is small.

Operators must ensure the setup is precise; slight misalignments in the graphite sleeves could lead to non-uniform heating, defeating the purpose of the equipment.

Sustainability and Optimization

While high power implies high energy consumption, modern laboratory furnaces allow for the optimization of heat treatment.

As noted in broader manufacturing contexts, optimizing these parameters is essential for adhering to environmental regulations.

Using the furnace inefficiently not only wastes energy but can yield materials that fail to meet sustainability or quality standards.

Making the Right Choice for Your Goal

To maximize the effectiveness of a high-power induction furnace in your VCS process, consider your specific objectives:

- If your primary focus is Product Homogeneity: Ensure the graphite sleeves are perfectly positioned to guarantee uniform heat transfer, triggering true global combustion.

- If your primary focus is Process Efficiency: Utilize the high heating rate to minimize cycle times, but calibrate the power carefully to avoid overshooting the ignition point.

The success of Volume Combustion Synthesis relies not just on the chemistry, but on the ability of your furnace to deliver intense, uniform energy in the shortest possible time.

Summary Table:

| Feature | Function in VCS | Benefit to Synthesis |

|---|---|---|

| Induction Currents | Rapid electromagnetic energy generation | Bypasses slow propagation phases |

| Graphite Sleeves | Indirect thermal transfer via superheating | Ensures uniform heat distribution |

| High Power Output | Critical energy spike for ignition | Triggers simultaneous global combustion |

| Thermal Precision | Controlled aggressive heating rates | Improves product homogeneity & structure |

Revolutionize Your Materials Synthesis with KINTEK

Precision and speed are the cornerstones of successful Volume Combustion Synthesis. Backed by expert R&D and world-class manufacturing, KINTEK provides high-power induction heating solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered to meet the aggressive heating rates required for advanced research.

Whether you need customizable lab furnaces or high-temperature industrial systems, our equipment ensures uniform energy delivery and superior product homogeneity. Optimize your heat treatment process today—Contact KINTEK for a custom consultation!

Visual Guide

References

- Gülizar Sarıyer, H. Erdem Çamurlu. Production and Characterization of Ni0.50 Al0.50 and Ni0.55 Al0.45 Powders by Volume Combustion Synthesis. DOI: 10.17776/csj.1280582

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What makes graphite crucible furnaces suitable for high-temperature applications? Unlock Precision and Purity

- Where is the target material placed in an induction heater and what happens to it? Discover the Science of Non-Contact Heating

- Why is repeated melting and flipping of alloy ingots necessary? Achieving Homogeneity in Mn–Ni–Fe–Si Alloys

- What are the key steps in the vacuum induction melting process? Achieve High-Purity Metal Alloys for Demanding Applications

- What are the advantages of considering future expansion when selecting an induction melting furnace? Boost Efficiency and Growth

- What makes induction heating suitable for precision applications? Achieve Unmatched Control for High-Performance Manufacturing

- What is a core type induction furnace? A Specialized Transformer for Efficient Metal Melting

- How does induction heating compare to resistance furnaces in ammonia decomposition? Experience Dynamic Precision Control