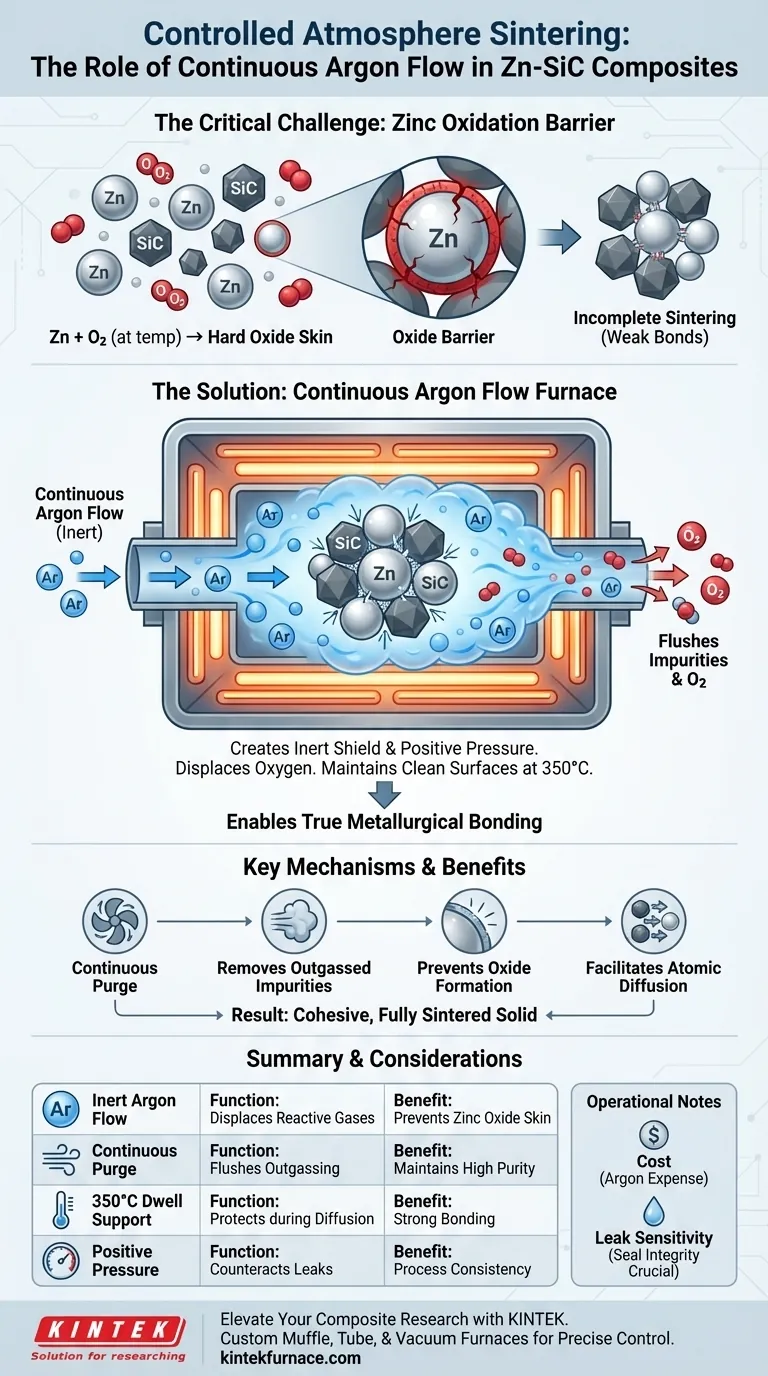

The primary function of a controlled atmosphere furnace with continuous argon flow is to establish a strictly inert environment that shields materials from atmospheric contamination. In the specific context of sintering Zn-SiC composites, this setup prevents the oxidation of zinc powder as temperatures rise to 350°C. By effectively displacing oxygen, the furnace ensures the zinc remains chemically pure, which is a prerequisite for successful sintering.

By maintaining a continuous flow of inert gas, the system eliminates the formation of oxide layers on particle surfaces. This removal of the "oxide barrier" is the defining factor that allows for true metallurgical bonding and structural integrity in zinc-based composites.

The Critical Challenge: Zinc Oxidation

Zinc’s Sensitivity to Oxygen

Zinc powder is highly reactive when exposed to oxygen, particularly as temperatures increase. Even before reaching the sintering target of 350°C, unprotected zinc particles will begin to react with the surrounding air.

The Barrier to Sintering

When zinc reacts with oxygen, it forms a hard oxide "skin" around each individual powder particle. This layer acts as a physical and chemical barrier.

If this oxide layer is allowed to form, the zinc particles cannot touch or fuse with one another or the silicon carbide (SiC) reinforcement. The result is incomplete sintering, leading to a composite with poor mechanical strength and low density.

How Continuous Argon Flow Solves the Problem

Creating an Inert Shield

Argon is a noble gas, meaning it is chemically inert and will not react with the zinc or the SiC. By filling the furnace chamber with argon, you create a neutral medium that supports heat transfer without chemical alteration.

The Importance of "Continuous" Flow

A static fill of argon is often insufficient because small leaks or outgassing from the material itself can reintroduce contaminants. A continuous flow actively purges the chamber.

This dynamic pressure ensures that any residual oxygen or volatile impurities released during heating are immediately flushed out of the system.

Facilitating Metallurgical Bonds

The ultimate goal of sintering is to create strong metallurgical bonds between particles.

Because the argon atmosphere prevents oxidation, the metal surfaces remain clean and active. This allows for atomic diffusion across particle boundaries at 350°C, resulting in a cohesive, fully sintered solid rather than a loosely packed aggregate.

Operational Constraints and Trade-offs

Process Cost and Complexity

While essential for quality, using continuous argon flow increases the operational cost of sintering. The consumption of high-purity argon represents a recurring expense compared to sintering in air (which is not an option for Zn).

Sensitivity to Leaks

The system relies entirely on the integrity of the furnace seals. Even a minor breach in the gas line or chamber seal can compromise the inert atmosphere.

If the flow rate is not sufficient to maintain positive pressure against a leak, oxygen ingress will occur, causing immediate degradation of the zinc powder.

Ensuring Success in Sintering Zn-SiC

To maximize the quality of your composite materials, consider the following regarding your atmosphere control:

- If your primary focus is mechanical strength: Prioritize high-purity argon and verify seal integrity to ensure zero oxidation, as this is the primary failure mode for bond strength.

- If your primary focus is process consistency: Implement flow monitoring to ensure the argon purge remains constant throughout the entire heating profile, specifically holding steady at the 350°C dwell time.

Effective sintering of zinc composites is impossible without total oxygen exclusion; the argon flow is not just an aid, but the fundamental enabler of the process.

Summary Table:

| Feature | Function in Zn-SiC Sintering | Benefit |

|---|---|---|

| Inert Argon Flow | Displaces oxygen and reactive gases | Prevents formation of zinc oxide 'skin' |

| Continuous Purge | Flushes out outgassed impurities | Maintains high-purity environment throughout cycle |

| 350°C Dwell Support | Protects surfaces during atomic diffusion | Facilitates strong metallurgical bonding |

| Positive Pressure | Counteracts potential chamber leaks | Ensures process consistency and material density |

Elevate Your Composite Material Research with KINTEK

Don't let oxidation compromise your structural integrity. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnace systems specifically engineered for precise atmosphere control. Backed by expert R&D and manufacturing, our systems are fully customizable to meet the unique requirements of your Zn-SiC or advanced material sintering processes.

Ready to achieve zero-oxidation results?

Contact our specialists today to find the perfect high-temperature solution for your lab.

Visual Guide

References

- Fabrication and analysis of Zn-SiC metal matrix composites via advanced metallurgical processes. DOI: 10.33545/26174693.2025.v9.i7se.4834

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How do industrial vacuum or atmosphere furnaces improve Inconel 718 after WAAM? Optimize Strength and Microstructure

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What are the two major categories of controlled atmosphere furnaces? Choose Batch or Continuous for Your Needs

- Why is a high-purity argon protective atmosphere required during carbonization? Achieve Optimal Carbon Structures

- What is a reducing atmosphere in a furnace? Essential for Preventing Oxidation and Enhancing Material Properties

- What type of atmosphere is a low vacuum furnace primarily designed for? Ideal for Inert Gas Heat Treatment

- What types of heat treatment processes benefit from a controlled atmosphere furnace? Enhance Material Properties with Precision

- What are sealed atmosphere furnaces called and what are their features? Discover Precision Heat Treatment Solutions