At its core, a controlled atmosphere furnace is essential for any high-temperature heat treatment process where the material's surface chemistry is critical. Key processes that benefit include annealing, brazing, sintering, carburizing, nitriding, carbonitriding, and neutral hardening. These furnaces provide a precisely managed environment, preventing unwanted chemical reactions like oxidation and enabling specific surface modifications.

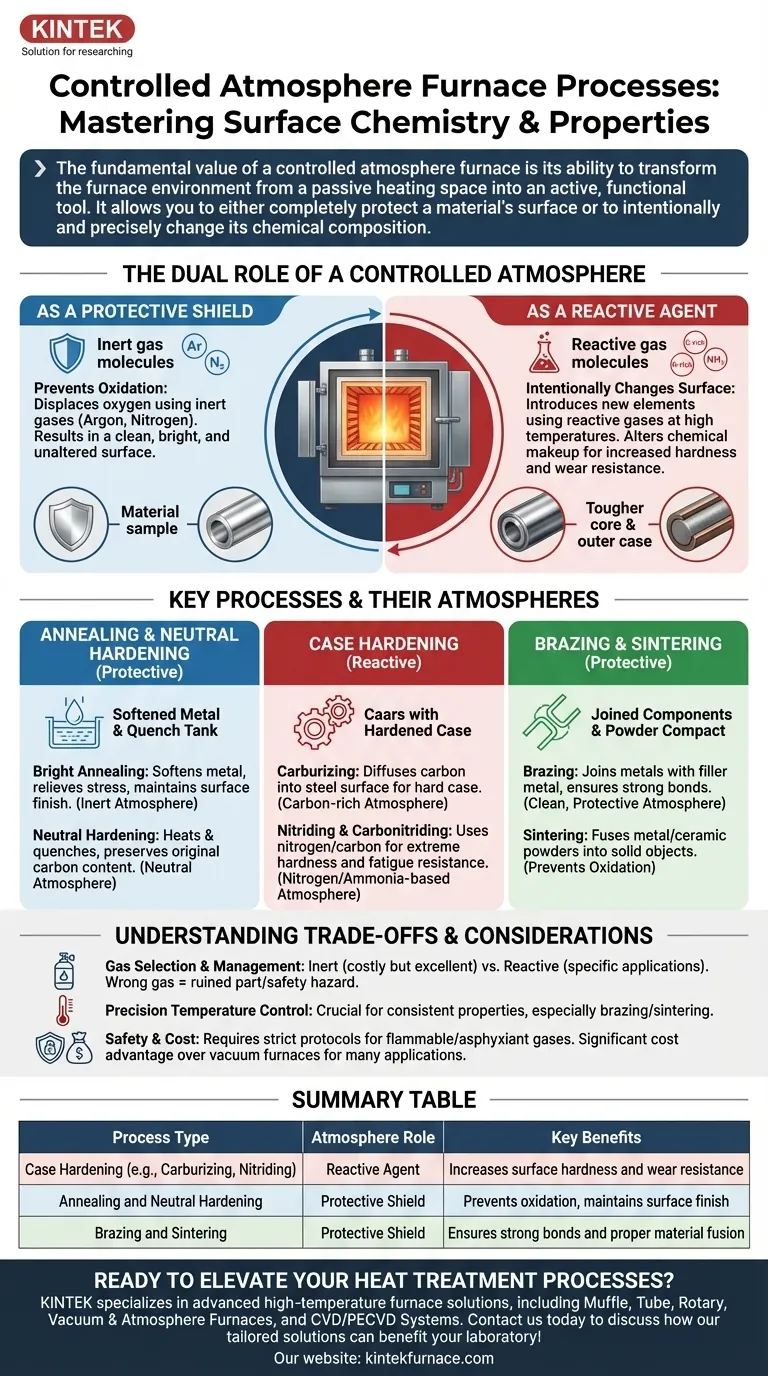

The fundamental value of a controlled atmosphere furnace is its ability to transform the furnace environment from a passive heating space into an active, functional tool. It allows you to either completely protect a material's surface or to intentionally and precisely change its chemical composition.

The Dual Role of a Controlled Atmosphere

The "atmosphere" inside the furnace isn't just air; it's a carefully selected gas or mixture of gases that serves one of two critical purposes. Understanding this distinction is key to selecting the right process.

As a Protective Shield

Many heat treatment processes require high temperatures that would cause materials, especially metals, to react with the oxygen in normal air. This reaction, known as oxidation, creates a layer of scale or discoloration on the surface.

A protective atmosphere, typically using inert gases like argon or nitrogen, displaces the oxygen. This prevents oxidation, ensuring the material emerges from the furnace with a clean, bright, and unaltered surface.

As a Reactive Agent

In other processes, the goal is not to protect the surface but to intentionally change it. This is known as case hardening.

Here, the furnace is filled with a chemically reactive gas that introduces new elements into the surface layer of the material at high temperatures. This alters the surface's chemical makeup to achieve desired properties, most commonly increased hardness and wear resistance.

Key Processes That Rely on Controlled Atmospheres

Different processes leverage the furnace's atmosphere in unique ways to achieve specific material outcomes.

Case Hardening (Carburizing, Nitriding)

These are reactive processes. Carburizing uses a carbon-rich atmosphere to diffuse carbon atoms into the surface of steel, creating a very hard outer "case" while leaving the core tough and ductile.

Nitriding and carbonitriding work similarly, using atmospheres rich in nitrogen (or nitrogen and carbon) to achieve extreme surface hardness and fatigue resistance.

Annealing and Neutral Hardening

Bright annealing is a protective process used to soften metal, relieve internal stresses, and improve ductility without damaging the surface finish. An inert atmosphere is crucial to prevent the oxidation that would otherwise occur.

Neutral hardening involves heating a part to harden it and then quenching it. The controlled atmosphere is "neutral," meaning it neither adds nor removes elements from the part's surface, preserving its original carbon content.

Brazing and Sintering

Brazing is a process for joining two pieces of metal using a filler metal that melts at a lower temperature. A protective atmosphere is essential to keep the base metals clean, allowing the filler metal to wet the surfaces properly and form a strong bond.

Sintering is used to create solid objects from metal or ceramic powders. A controlled atmosphere prevents oxidation of the fine particles, allowing them to fuse together correctly under heat and pressure.

Understanding the Trade-offs and Considerations

While powerful, controlled atmosphere furnaces require careful management and understanding of their operational principles.

Gas Selection and Management

The choice of atmosphere is the most critical decision. An inert gas like argon is excellent for protection but can be costly. A nitrogen/hydrogen mix can be a more economical protective atmosphere, while endothermic or ammonia-based gases are used for reactive processes. The wrong gas can ruin the workpiece or create a safety hazard.

Precision Temperature Control

In all these processes, temperature is just as critical as the atmosphere. The furnace must maintain a precise and uniform temperature to ensure consistent material properties. This is especially true for brazing and sintering, where slight deviations can compromise the integrity of the final product.

Safety and Cost

Handling flammable (hydrogen) or asphyxiant (nitrogen, argon) gases requires strict safety protocols, proper ventilation, and trained operators. However, for many applications, these furnaces represent a significant cost advantage over vacuum furnaces while providing the necessary environmental control to achieve high-quality results.

Making the Right Choice for Your Goal

Your final objective determines how you should leverage a controlled atmosphere.

- If your primary focus is surface hardening: You need a reactive atmosphere for processes like carburizing or nitriding to chemically alter the part's surface.

- If your primary focus is preserving surface finish and integrity: You need a protective, inert atmosphere for processes like bright annealing, neutral hardening, or brazing to prevent oxidation.

- If your primary focus is joining components or consolidating powders: A clean, protective atmosphere is non-negotiable for brazing and sintering to ensure strong, oxide-free bonds.

Ultimately, mastering the furnace atmosphere gives you direct control over the final chemical and physical properties of your material.

Summary Table:

| Process Type | Atmosphere Role | Key Benefits |

|---|---|---|

| Case Hardening (e.g., Carburizing, Nitriding) | Reactive Agent | Increases surface hardness and wear resistance |

| Annealing and Neutral Hardening | Protective Shield | Prevents oxidation, maintains surface finish |

| Brazing and Sintering | Protective Shield | Ensures strong bonds and proper material fusion |

Ready to elevate your heat treatment processes? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring precise temperature control, enhanced material properties, and cost-effective operations. Contact us today to discuss how our tailored solutions can benefit your laboratory!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- What does nitrogen do in a furnace? Create an Inert, Oxygen-Free Atmosphere for Superior Results