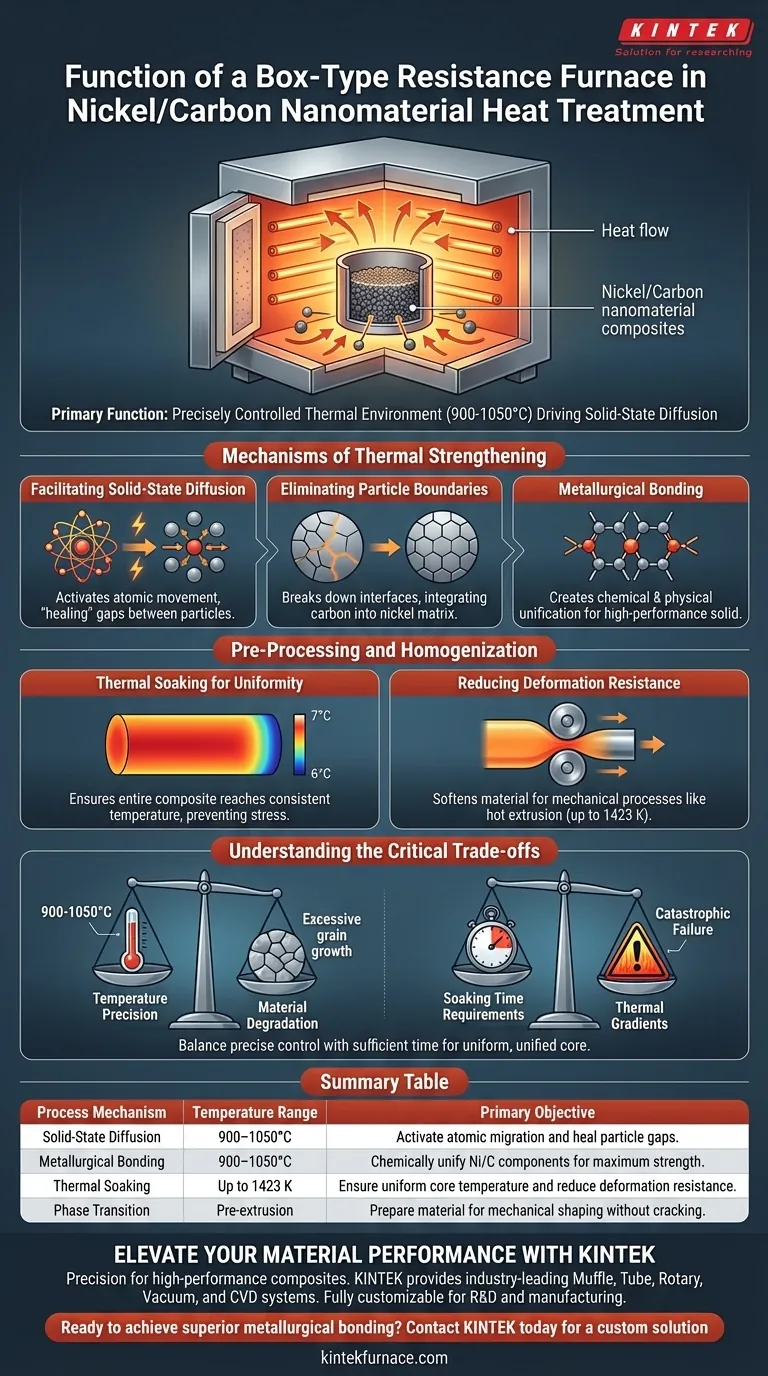

The primary function of a box-type resistance furnace in this context is to create a precisely controlled thermal environment that drives solid-state diffusion within nickel/carbon nanomaterial composites. By maintaining temperatures typically between 900 and 1050 degrees Celsius, the furnace provides the thermal energy required to eliminate particle boundaries, resulting in the metallurgical bonding and final strengthening of the material.

By providing a consistent thermal soak, the furnace promotes atomic migration across material interfaces. This process transforms discrete particles into a unified, strengthened composite by reducing deformation resistance and enabling solid-state diffusion.

The Mechanisms of Thermal Strengthening

Facilitating Solid-State Diffusion

The core objective of the heating process is to activate atomic movement without melting the material.

The furnace maintains a specific high-temperature range (900–1050°C) which energizes the atoms within the nickel matrix.

This energy allows atoms to migrate across the interfaces of the nanomaterials, effectively "healing" the gaps between particles through diffusion.

Eliminating Particle Boundaries

Before heat treatment, the composite consists of distinct, separate boundaries between the nickel and carbon components.

The constant thermal environment provided by the box furnace breaks down these boundaries.

As atomic migration occurs, the distinct interfaces fade, integrating the carbon nanomaterials firmly into the nickel matrix.

Metallurgical Bonding

The ultimate result of this thermal processing is metallurgical bonding.

This is not merely sticking materials together; it is a chemical and physical unification that significantly increases the material's strength.

This bonding is essential for ensuring the composite behaves as a single, high-performance solid rather than a loose aggregate of parts.

Pre-Processing and Homogenization

Thermal Soaking for Uniformity

Beyond strengthening, the furnace is utilized for pre-sintering and "soaking" treatments, particularly before mechanical processes like hot extrusion.

This ensures that the entire encapsulated composite billet reaches a uniform temperature throughout its volume.

Uniform heating prevents internal stress and ensures consistent material properties across the entire cross-section.

Reducing Deformation Resistance

Heating the composite significantly alters its mechanical state to prepare it for further shaping.

By reaching temperatures above the beta phase transition point (up to 1423 K in some pre-extrusion contexts), the material's resistance to deformation is lowered.

This thermal softening is critical for allowing the material to be extruded or shaped without cracking or requiring excessive force.

Understanding the Critical Trade-offs

Temperature Precision vs. Material Degradation

While high heat is necessary for diffusion, there is a strict upper limit to effective processing.

Exceeding the optimal temperature range (e.g., surpassing 1050°C significantly without cause) can lead to excessive grain growth, which paradoxically weakens the material.

Conversely, failing to reach the threshold results in incomplete diffusion and weak interfacial bonds.

Soaking Time Requirements

Achieving a uniform core temperature ("soaking") is a time-intensive process, especially for larger billets.

Rushing this process leads to thermal gradients where the outside is soft but the center remains hard.

This lack of uniformity can cause catastrophic failure during subsequent processing steps like hot extrusion.

Making the Right Choice for Your Goal

To maximize the efficacy of a box-type resistance furnace in your heat treatment process, align your parameters with your specific metallurgical objectives.

- If your primary focus is Maximum Strength: Prioritize the 900–1050°C range to maximize solid-state diffusion and metallurgical bonding without inducing grain growth.

- If your primary focus is Processability (e.g., Extrusion): Ensure a thorough "soaking" period to achieve uniform heat distribution and reduce deformation resistance before mechanical forming.

Success relies on balancing precise temperature control with sufficient soaking time to ensure the composite is unified at the atomic level.

Summary Table:

| Process Mechanism | Temperature Range | Primary Objective |

|---|---|---|

| Solid-State Diffusion | 900–1050°C | Activate atomic migration and heal particle gaps. |

| Metallurgical Bonding | 900–1050°C | Chemically unify Ni/C components for maximum strength. |

| Thermal Soaking | Up to 1423 K | Ensure uniform core temperature and reduce deformation resistance. |

| Phase Transition | Pre-extrusion | Prepare material for mechanical shaping without cracking. |

Elevate Your Material Performance with KINTEK

Precision is the difference between a high-performance composite and material failure. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed to give you absolute control over solid-state diffusion and thermal soaking.

Whether you are processing nickel/carbon nanomaterials or specialized alloys, our lab high-temperature furnaces are fully customizable to meet your unique R&D and manufacturing requirements.

Ready to achieve superior metallurgical bonding?

Contact KINTEK today for a custom solution

Visual Guide

References

- Hermansyah Aziz, Ibrahim k. salman. Effect of Adding Nano Carbon on Density, Porosity, and Water Absorption of Nickel by Powder Metallurgy. DOI: 10.55810/2313-0083.1102

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary principle of a muffle furnace? Achieve Clean, Contamination-Free Heating for Your Materials

- What is the technical role of a muffle furnace in dyeing sludge ash preparation? Optimize Pozzolanic Activation

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation

- What is important about chamber size in muffle furnaces? Ensure Accurate Heating with the Right Zone

- What electrical safety measures are required for a muffle furnace? Essential Steps to Prevent Electric Shock and Fire

- How does an electric furnace contribute to energy efficiency? Maximize Your Lab's Heating Performance

- How is a box muffle furnace used in chemical experiments? Unlock Precise High-Temperature Processing

- What is the role of a high-temperature muffle furnace in glucose sensor prep? Optimize Metal Oxide Phase Transitions