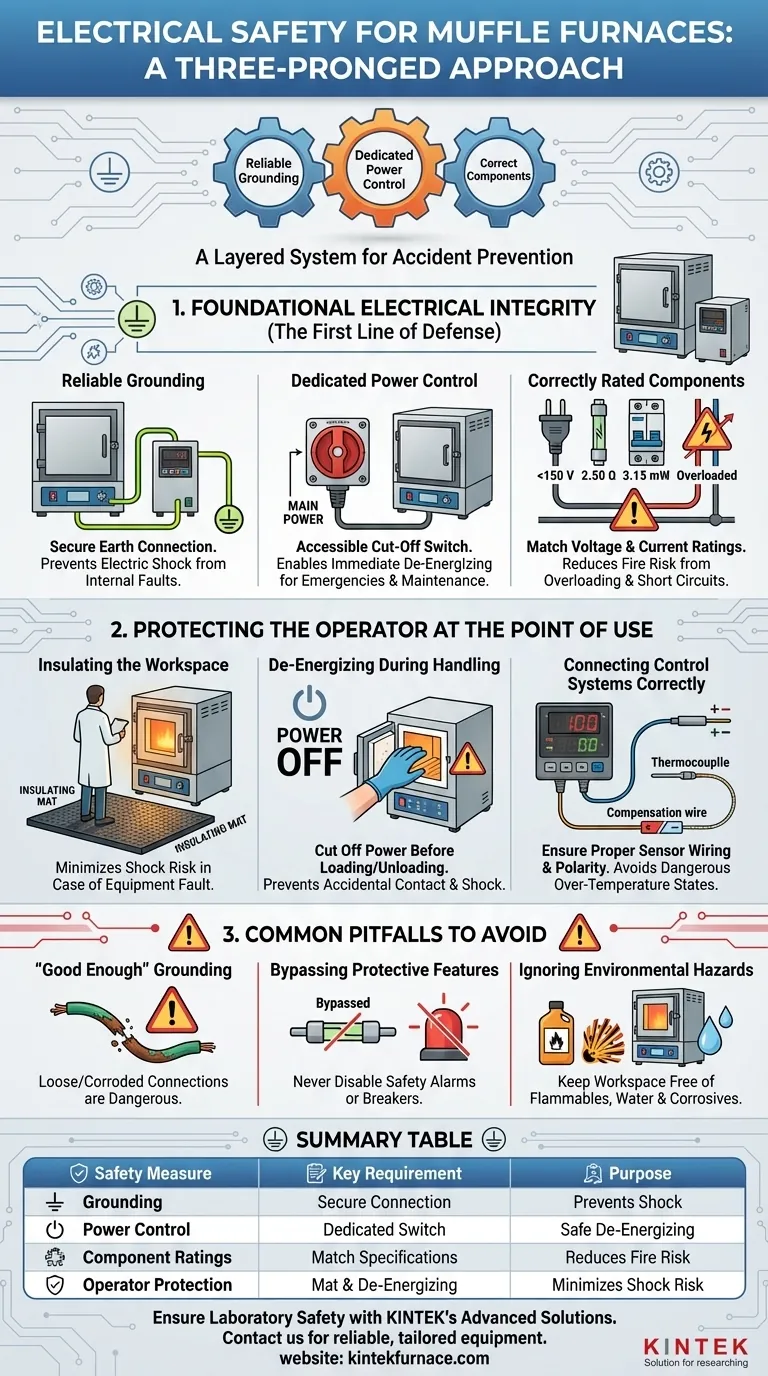

At its core, ensuring electrical safety for a muffle furnace requires a three-pronged approach: reliable grounding, a dedicated and accessible power control system, and the use of correctly rated electrical components like plugs, fuses, and circuit breakers. Both the furnace and its controller must be connected to a verified earth ground to prevent electric shock in the event of an internal fault.

Muffle furnaces combine high temperatures with significant electrical power, creating inherent risks. A robust electrical safety strategy is not about a single solution, but a layered system of physical installation, operator procedures, and built-in protective features that work together to prevent accidents.

Foundational Electrical Integrity: The First Line of Defense

The initial setup of your furnace's electrical supply is the most critical factor in its safe operation. Errors at this stage compromise all other safety efforts.

Ensuring Reliable Grounding

The furnace shell and its separate controller shell must both be securely connected to a proper ground wire. This is not optional.

Grounding provides a safe path for electrical current to flow in the event of an internal short circuit, preventing the furnace's metal casing from becoming dangerously energized and causing a severe electric shock.

Installing a Dedicated Power Control

A dedicated, clearly marked power switch or circuit breaker should be installed at the power line inlet. This switch must control the main power supply to the entire furnace system.

This external cut-off ensures you have an immediate and unambiguous way to de-energize the equipment during an emergency or before performing any maintenance or sample handling.

Using Correctly Rated Components

The plugs, sockets, wiring, and fuses or circuit breakers used must match the furnace’s specified voltage and current rating. Using underrated components creates a significant fire hazard.

Overloading a circuit can cause wires to overheat and insulation to melt, leading to short circuits and fire. Fuses and breakers are non-negotiable safety devices designed to interrupt the circuit before this happens.

Protecting the Operator at the Point of Use

Beyond the foundational wiring, specific measures and procedures are required to protect the person directly interacting with the furnace.

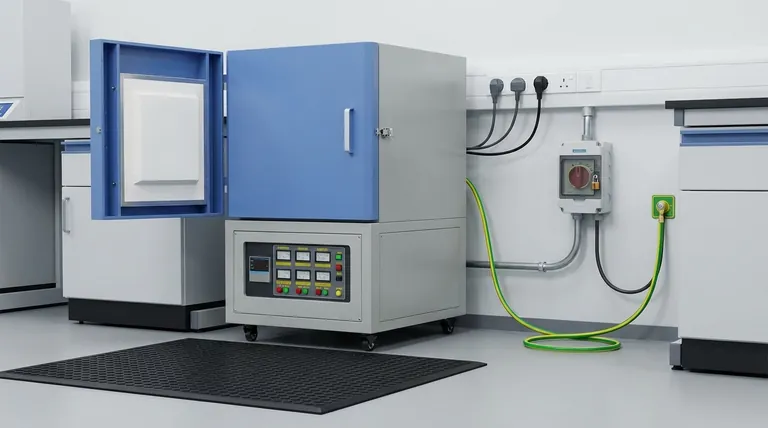

Insulating the Workspace

For an added layer of safety, a thick rubber insulating mat should be placed on the floor in front of the furnace.

This mat provides electrical insulation for the operator, reducing the risk of a dangerous electrical circuit being completed through their body in the case of an equipment fault combined with a wet floor or other conductive path.

De-Energizing During Handling

Power must be cut off completely before loading or taking samples from the furnace. This is a critical procedural rule.

Opening the furnace door while it is energized exposes heating elements and internal wiring, creating a risk of accidental contact and severe electric shock.

Connecting Control Systems Correctly

Ensure that any external sensors, like a thermocouple, are connected to the controller using the correct type of wire (e.g., compensation wire) and with the correct polarity.

Incorrect wiring can cause the controller to receive false temperature readings, potentially leading the furnace to a dangerous over-temperature state or masking a serious fault.

Common Pitfalls and Risks to Avoid

Trust in the equipment can lead to complacency. Understanding common failure points is key to maintaining a vigilant safety posture.

The Fallacy of "Good Enough" Grounding

A loose, corroded, or improperly installed ground wire is as dangerous as having no ground wire at all. The connection must be mechanically secure and electrically solid, and it should be periodically inspected.

Bypassing Protective Features

Never disable or bypass built-in safety features like over-temperature protection alarms or circuit breakers. These are your last line of defense against catastrophic equipment failure, fire, and other accidents.

Ignoring Environmental Hazards

The furnace must be operated in a workspace free of flammable materials, explosives, or corrosive substances. The presence of water or other liquids dramatically increases the risk of electric shock and can damage the furnace.

Making the Right Choice for Your Goal

Your safety protocol should align with your role, whether you are installing the equipment, operating it daily, or performing maintenance.

- If your primary focus is initial installation: Verify the circuit's capacity, install a dedicated cut-off switch, and confirm a proper earth ground connection before the furnace is ever powered on.

- If your primary focus is daily operation: Always de-energize the furnace before loading or unloading samples and use an insulating mat as a standard precaution.

- If your primary focus is long-term maintenance: Regularly inspect all wiring, plugs, and grounding connections for wear or damage, and test built-in safety features according to the manufacturer's schedule.

Ultimately, electrical safety is a continuous process of diligence, not a one-time setup.

Summary Table:

| Safety Measure | Key Requirement | Purpose |

|---|---|---|

| Grounding | Secure connection to earth ground for furnace and controller | Prevents electric shock from internal faults |

| Power Control | Dedicated, accessible switch or circuit breaker | Allows emergency de-energizing and safe maintenance |

| Component Ratings | Use plugs, fuses, and wiring matching furnace specifications | Reduces fire risk from overloading and short circuits |

| Operator Protection | Insulating mats and de-energizing during sample handling | Minimizes shock risk and ensures safe operation |

Ensure your laboratory's safety with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Contact us today for reliable, tailored equipment that prioritizes electrical safety and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency