At its core, a porcelain furnace is a specialized, high-temperature oven used in dental laboratories to transform ceramic materials into durable and aesthetic dental restorations. It applies precisely controlled heat to fire, sinter, and glaze materials like porcelain, which are used to fabricate crowns, bridges, veneers, and inlays.

The furnace is more than a simple heater; it is a precision instrument at the heart of restorative dentistry. Its fundamental purpose is to convert raw ceramic powders into strong, dense, and lifelike prosthetics through meticulously managed heating and cooling cycles.

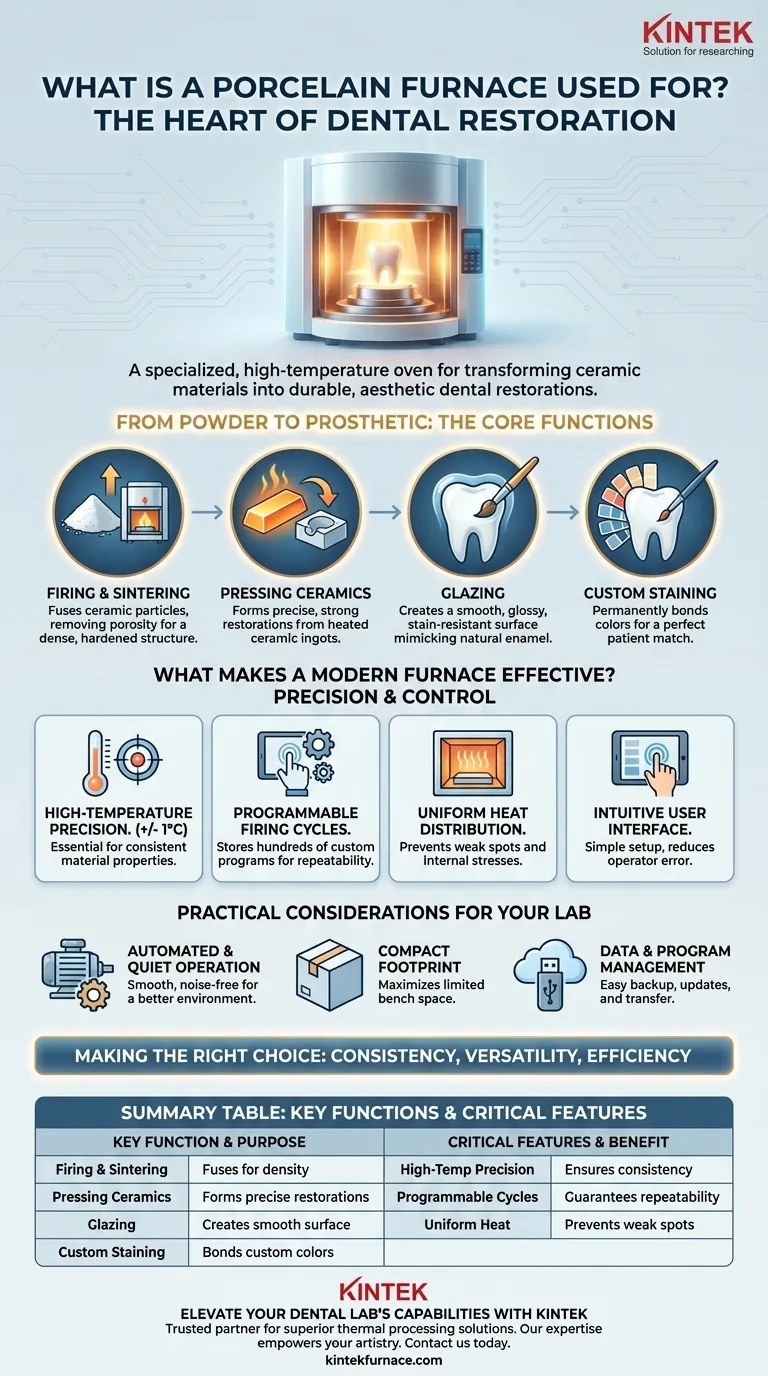

From Powder to Prosthetic: The Furnace's Core Functions

A porcelain furnace is not used for a single action, but for a sequence of processes that build, strengthen, and finish a dental restoration. Each function relies on the furnace's ability to deliver precise thermal energy.

Firing and Sintering

This is the primary function. Raw ceramic powder is layered to create the shape of the restoration, which is then heated in the furnace. The heat fuses (or sinters) the ceramic particles together, shrinking the material, removing porosity, and creating a dense, hardened structure.

Pressing Ceramics

Some furnaces are equipped for "pressing" ceramics. In this process, a heated ceramic ingot is pressed into a mold to create an extremely precise and strong restoration. This is a common method for fabricating monolithic crowns and bridges.

Glazing for a Natural Finish

After the restoration is shaped and sintered, a final glaze layer is applied and fired at a specific temperature. This glazing cycle creates a smooth, non-porous, and glossy surface that mimics the luster of natural tooth enamel and provides stain resistance.

Custom Staining and Characterization

To achieve a perfect match with a patient's existing teeth, technicians apply custom stains and colors to the surface of the restoration. The furnace is then used for a low-temperature firing cycle that permanently bonds these colors to the ceramic.

What Makes a Modern Furnace Effective?

The difference between an adequate restoration and an exceptional one often comes down to the capabilities of the furnace. Modern units are defined by their precision, control, and efficiency.

High-Temperature Precision

The most critical feature is the ability to maintain temperature accuracy, often within +/- 1° Celsius. This consistency is vital because different ceramic materials have very specific firing temperatures. Deviations can lead to a weak or aesthetically flawed restoration. This is often achieved with high-quality heating elements, such as those made from molybdenum disilicide.

Programmable Firing Cycles

Technicians work with dozens of different ceramic systems, each with unique requirements. Modern furnaces allow users to create, store, and recall hundreds of custom programs. This ensures repeatability and efficiency, as the exact parameters for temperature ramps, holds, and cooling can be executed flawlessly every time.

Uniform Heat Distribution

The furnace's heating chamber is engineered to distribute heat evenly. This ensures that the entire restoration—whether a thin veneer or a large bridge—is sintered uniformly, preventing weak spots or internal stresses from developing.

Intuitive User Interface

Despite the complex processes they manage, modern furnaces feature simple, touch-screen interfaces. The goal is to allow a technician to set up and run a cycle quickly and with minimal training, reducing the chance of operator error.

Understanding the Practical Considerations

While a furnace's technical specifications are paramount, its practical design features have a significant impact on laboratory workflow and the quality of the work environment.

Automated and Quiet Operation

Many units feature precision stepper motor drives for the lift mechanism. This ensures smooth, vibration-free movement, which is critical when handling delicate restorations. It also contributes to a noise-free operating environment, which is a significant benefit in a busy lab.

Compact Footprint

Dental laboratories often have limited bench space. Manufacturers have focused on creating powerful furnaces with a compact design to maximize efficiency without sacrificing performance.

Data and Program Management

Features like USB connectivity are no longer a luxury. They allow for easy backup of firing programs, software updates, and transferring programs between multiple furnaces, ensuring consistency across a laboratory's production.

Making the Right Choice for Your Goal

Selecting a furnace depends entirely on the specific needs of the dental laboratory.

- If your primary focus is consistency and high-volume production: Prioritize furnaces with exceptional temperature precision (+/- 1°C), advanced programming, and data management via USB.

- If your primary focus is versatility: Select a "combi" furnace that offers both traditional firing and pressing capabilities to handle the widest range of ceramic materials and restoration types.

- If your primary focus is ease of use and workflow efficiency: Look for models with a highly intuitive touch-screen interface, pre-loaded programs, and clear operational status displays.

Ultimately, the porcelain furnace is the indispensable tool that bridges the gap between the technician's artistry and the material's scientific potential.

Summary Table:

| Key Function | Purpose |

|---|---|

| Firing & Sintering | Fuses ceramic particles to create a dense, hardened structure. |

| Pressing Ceramics | Forms precise, strong restorations from heated ceramic ingots. |

| Glazing | Creates a smooth, glossy, stain-resistant surface that mimics enamel. |

| Custom Staining | Permanently bonds custom colors for a perfect tooth match. |

| Critical Features | Benefit |

| High-Temperature Precision (+/- 1°C) | Ensures consistent, strong, and aesthetically flawless results. |

| Programmable Firing Cycles | Guarantees repeatability and efficiency for different ceramic materials. |

| Uniform Heat Distribution | Prevents weak spots and internal stresses in the restoration. |

Elevate Your Dental Lab's Capabilities with KINTEK

Just as a modern porcelain furnace is the precision instrument at the heart of restorative dentistry, KINTEK is the trusted partner for laboratories demanding superior thermal processing solutions. Our expertise in high-temperature technology, honed through decades of R&D and in-house manufacturing, directly translates to the dental field.

We understand that achieving consistent, high-quality dental restorations requires unparalleled temperature control, uniform heating, and reliable, repeatable cycles—the same principles that define our advanced furnace systems.

Let KINTEK's engineering excellence empower your artistry. Whether you need a standard solution or a deeply customized system to meet your unique workflow and material requirements, our team is ready to help. Contact us today to discuss how we can provide the thermal precision your laboratory deserves.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations