At its core, a dental ceramic furnace is a specialized, high-temperature oven used in dental laboratories to craft durable and aesthetic restorations like crowns, bridges, and veneers. It transforms raw ceramic materials into their final, hardened state through a precisely controlled heating and cooling process known as firing or sintering. This equipment is indispensable for achieving the strength, fit, and appearance required for modern dental prosthetics.

A dental furnace is not merely an oven; it is a precision instrument that enables dental technicians to transform delicate ceramic powders into strong, perfectly-fitting, and lifelike tooth restorations by applying carefully engineered thermal cycles.

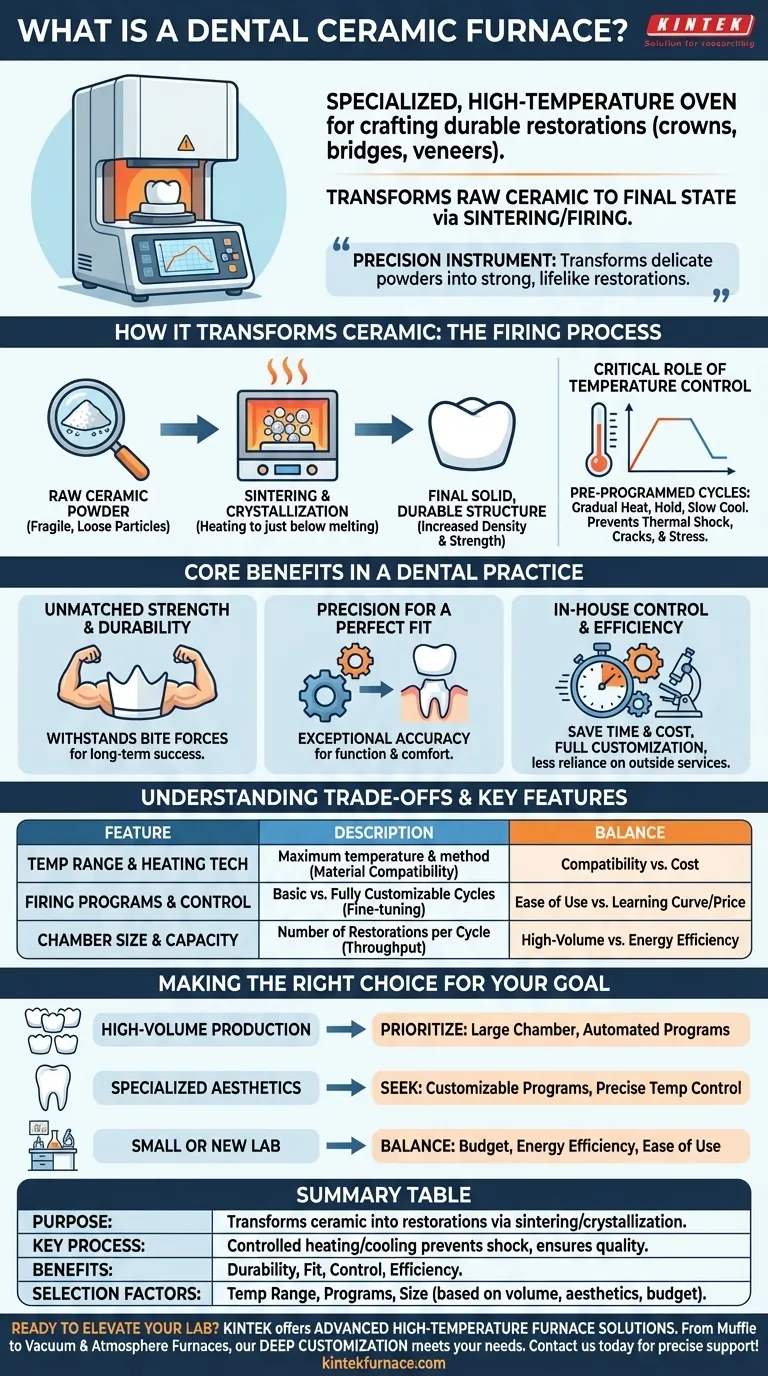

How a Dental Furnace Transforms Ceramic

To understand the furnace's importance, you must first understand the material it works with. The process is a fundamental transformation from a fragile state to a highly durable one.

The Firing Process: Sintering and Crystallization

The core function of the furnace is to sinter the ceramic. This involves heating the material to a temperature just below its melting point.

At this high temperature, the individual ceramic particles fuse, dramatically increasing the material's density and strength. This process, also involving crystallization, creates the final solid and durable structure.

The Critical Role of Temperature Control

A dental furnace is defined by its precision. It executes pre-programmed heating and cooling cycles that are tailored to specific ceramic materials.

The temperature is increased gradually to the target, held for a specific duration, and then cooled slowly. This controlled cycle is crucial for preventing thermal shock, which could cause cracks or internal stress in the final restoration.

The Core Benefits in a Dental Practice

Using a dedicated ceramic furnace provides benefits that directly impact the quality of patient care and the efficiency of the dental lab.

Unmatched Strength and Durability

The firing process produces an extremely hard ceramic restoration capable of withstanding the significant bite forces present in a patient's mouth. This durability is essential for the long-term success of the prosthetic.

Precision for a Perfect Fit

High-quality furnaces deliver exceptional accuracy. This ensures that the final crown, bridge, or veneer fits the patient's preparation perfectly, which is critical for both function and comfort.

In-House Control and Efficiency

Bringing this capability in-house allows a dental practice or lab to save significant time and cost. It eliminates the reliance on outside services and gives technicians full control over customization for individual patient needs, enhancing the overall quality of service.

Understanding the Trade-offs and Key Features

When evaluating a dental furnace, several key features determine its capability and suitability for a specific lab's needs. Understanding these involves balancing performance with cost.

Temperature Range and Heating Technology

The maximum temperature and the method of heating are the most fundamental specifications. Different ceramics require different firing temperatures, so the furnace must be compatible with the materials you intend to use.

Firing Programs and Control

Furnaces range from having a few basic, pre-set programs to offering fully customizable cycles. More advanced control allows technicians to fine-tune the process for specialized or challenging cases but often comes with a steeper learning curve and higher price.

Chamber Size and Capacity

The size of the firing chamber dictates how many restorations can be processed in a single cycle. A larger capacity improves throughput for high-volume labs, while a smaller chamber may be more energy-efficient for smaller practices.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on your lab's specific operational priorities.

- If your primary focus is high-volume production: Prioritize a furnace with a large chamber capacity and reliable, automated firing programs to maximize throughput.

- If your primary focus is specialized, aesthetic restorations: Seek a furnace with highly customizable programs and exceptionally precise temperature control for ultimate artistic freedom.

- If your primary focus is integrating into a small or new lab: Balance the initial budget with energy efficiency, ease of use, and strong manufacturer support.

Ultimately, this specialized equipment empowers you to deliver predictable, high-quality results for every patient.

Summary Table:

| Feature | Description |

|---|---|

| Purpose | Transforms ceramic materials into durable dental restorations (e.g., crowns, bridges) via sintering and crystallization. |

| Key Process | Controlled heating and cooling cycles prevent thermal shock and ensure strength, fit, and aesthetics. |

| Benefits | Unmatched durability, precise fit, in-house control for customization, and improved lab efficiency. |

| Selection Factors | Temperature range, firing programs, chamber size; choose based on production volume, aesthetics, or budget. |

Ready to elevate your dental lab's capabilities? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Whether you're focused on high-volume output, specialized aesthetics, or seamless integration into a new setup, our furnaces deliver reliable performance and enhanced efficiency. Contact us today to discuss how we can support your goals with precision and expertise!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations