In short, after being created in the plasma, reactive species travel to the substrate surface where they stick, react, and build up a solid film. The process is a carefully controlled sequence involving diffusion, adsorption, surface reaction, and the constant removal of waste products to ensure the quality of the final material.

The journey of a reactive species is not a random collision, but a multi-stage process. Understanding this path—from creation in the plasma to its final reaction on a surface—is the key to controlling the properties of the film you are creating.

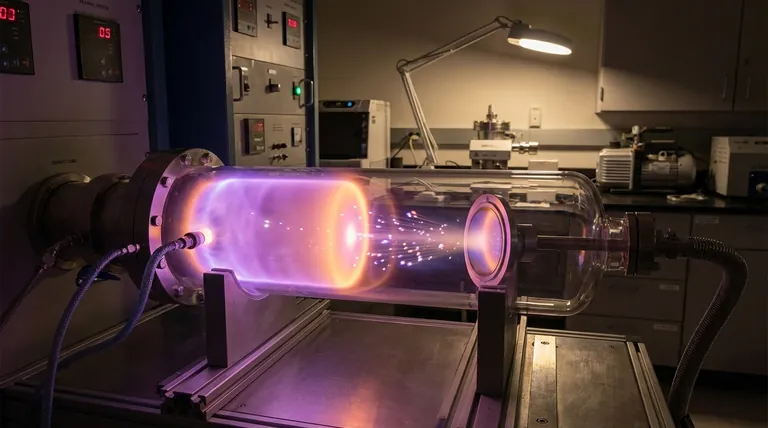

The Journey from Plasma to Solid Film

Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a process of building thin films atom by atom. The fate of the reactive species generated in the plasma is the central mechanism that makes this possible.

Step 1: Creation Within the Plasma

An electrical voltage is applied to a precursor gas inside a vacuum chamber. This energy breaks the gas molecules apart, creating a mixture of highly reactive species, including ions, electrons, and, most importantly, neutral radicals. These radicals are often the primary building blocks for the film.

Step 2: Diffusion Through the Sheath

A boundary layer, known as the plasma sheath, forms between the glowing bulk plasma and the substrate. The reactive species must travel across this region to reach the surface where deposition occurs. Neutral radicals diffuse across it, while charged ions are accelerated by the electric field within the sheath.

Step 3: Adsorption onto the Substrate

When a reactive species reaches the substrate, it must first stick to the surface in a process called adsorption. This is a critical step that transitions the species from a gas phase to a surface-bound state, making it available for chemical reactions.

Step 4: Surface Reactions and Film Growth

Once adsorbed, the reactive species move around on the surface, find other reactants, and undergo chemical reactions. These reactions bond them together, forming the desired solid material. This process repeats continuously, building up the thin film layer by layer.

Step 5: Removal of Unwanted Byproducts

The chemical reactions that form the film also create waste gases, or byproducts. A powerful vacuum pumping system, often a combination of turbomolecular and roughing pumps, constantly removes these byproducts from the chamber. This prevents them from being incorporated into the film as impurities and ensures the deposition reaction can continue efficiently.

Understanding the Critical Factors

The seemingly simple path of a reactive species is influenced by several factors that have a direct impact on the final film. Mastering these gives you control over the material's properties.

The Distinct Roles of Ions vs. Radicals

Radicals are electrically neutral and are typically the main contributors to film growth (deposition rate). Their journey is governed by diffusion.

Ions, being charged, are accelerated by the electric field in the sheath. They bombard the growing film, which can be beneficial. This bombardment compacts the film, increasing its density and modifying its internal stress. However, excessive ion energy can cause damage.

The Importance of Process Pressure

Lowering the pressure inside the chamber increases the "mean free path," or the average distance a species can travel before hitting another. This changes the flux and energy of species reaching the substrate, directly affecting film uniformity and properties.

The Consequence of Inefficient Pumping

If byproducts are not removed effectively, they can contaminate the process. They may either get trapped in the growing film, creating defects and compromising its purity, or they can alter the chemistry of the plasma itself, leading to inconsistent deposition.

How to Apply This to Your Process

Understanding the journey of reactive species allows you to diagnose problems and tune your process to achieve specific goals.

- If your primary focus is a high deposition rate: Your goal is to maximize the creation and transport of neutral radicals to the surface.

- If your primary focus is a dense, hard film: Your goal is to use controlled ion bombardment (by adjusting RF power or bias) to compact the film as it grows.

- If your primary focus is low film stress: Your goal is to find a balance between deposition temperature and ion energy to prevent the film from pulling apart or compressing itself.

- If your primary focus is high film purity: Your goal is to ensure your precursor gases are clean and your vacuum pumping is highly efficient at removing reaction byproducts.

By controlling the environment these reactive species travel through, you are directly controlling the synthesis of your material.

Summary Table:

| Stage | Key Process | Outcome |

|---|---|---|

| Creation | Plasma breaks gas molecules | Forms ions, electrons, and radicals |

| Diffusion | Species travel through plasma sheath | Radicals diffuse; ions accelerate |

| Adsorption | Species stick to substrate surface | Enables surface reactions |

| Reaction | Surface reactions bond species | Builds solid film layer by layer |

| Byproduct Removal | Vacuum pumps remove waste gases | Ensures film purity and efficiency |

Ready to optimize your PECVD process for superior thin films? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing deposition rates, film density, and purity. Contact us today to discuss how our tailored solutions can elevate your laboratory's performance!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What are the applications of PECVD? Unlock Low-Temperature Thin-Film Deposition