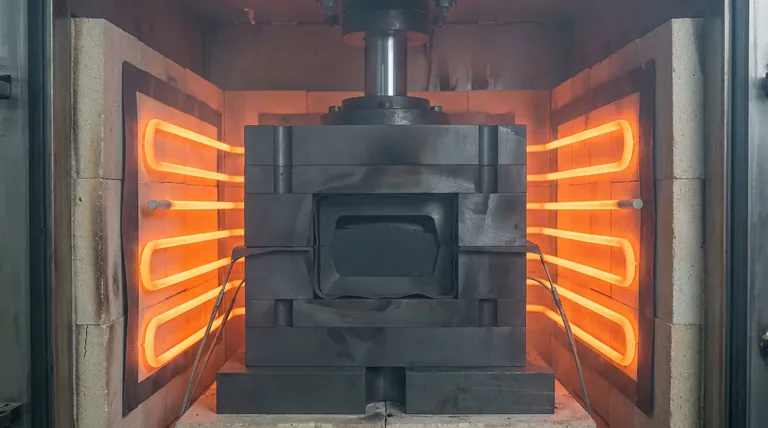

High-purity graphite molds function as far more than passive containers; they are active mechanical components essential for the densification of Silicon Carbide (SiC). In the hot pressing process, these molds serve two simultaneous, critical roles: they act as the precise shaping vessel for the ceramic powder and as the primary vehicle for transmitting massive axial pressure to the sample.

Core Takeaway: High-purity graphite provides the unique combination of thermal conductivity and high-temperature mechanical strength required to sinter SiC. It acts as a shaping container that facilitates uniform heating while simultaneously transmitting extreme axial pressures (>30 MPa) to drive particle rearrangement and densification.

The Dual-Role of Containment and Mechanics

The primary function of the mold is to bridge the gap between simple containment and active mechanical processing.

Precise Geometric Shaping

At the most fundamental level, the graphite mold serves as the container for sample shaping.

It constrains the SiC powder, defining the final geometry of the ceramic component.

Because graphite maintains dimensional stability at extreme temperatures, it ensures the sample does not deform or collapse during the initial stages of sintering.

High-Pressure Transmission

Unlike pressureless sintering, hot pressing relies on force to achieve density.

The graphite mold serves as the core component for pressure transmission.

It must withstand axial pressures exceeding 30 MPa without fracturing. The mold effectively transfers the force from the hydraulic rams directly to the ceramic powder, driving particle rearrangement and eliminating voids.

Thermal Management Functions

Silicon Carbide requires high temperatures to sinter, making thermal management just as critical as mechanical pressure.

Ensuring Uniform Heating

Graphite possesses excellent thermal conductivity.

This property allows the mold to distribute heat evenly around the SiC sample, eliminating thermal gradients.

Uniform heating is vital for preventing internal stresses, cracking, or uneven densification within the ceramic body.

Withstanding Extreme Environments

The sintering of SiC often occurs at temperatures that would melt or weaken other tooling materials.

High-purity graphite maintains its high-temperature strength well beyond 2000°C.

This allows the process to reach the necessary activation energy for SiC densification without the mold failing structurally.

Surface Interaction and Demolding

The interface between the mold and the ceramic is a critical failure point if not managed correctly.

Preventing Chemical Adhesion

At high temperatures, ceramic powders can react with or stick to the mold walls.

To counter this, high-purity graphite molds are often used in conjunction with graphite paper.

This functions as a separation layer that prevents the SiC sample from sticking to the rigid mold, facilitating easier demolding and preserving the surface finish of the ceramic.

Creating a Protective Atmosphere

While primarily a physical barrier, graphite also creates a micro-reducing atmosphere.

At high temperatures, the graphite consumes residual oxygen, helping to suppress micro-oxidation on the sample surface.

This helps maintain the chemical integrity of the material, though it is a secondary benefit to the mechanical roles.

Understanding the Trade-offs

While high-purity graphite is the standard for hot pressing, it introduces specific limitations and risks that must be managed.

Oxidation Vulnerability

Graphite oxidizes rapidly in air at high temperatures.

To prevent rapid mold degradation (burning away), hot pressing must occur in a vacuum or inert gas atmosphere.

In a vacuum, a mold may last for over 30 cycles; in air, it may last only 4-5 uses before losing dimensional accuracy.

Carbon Diffusion Risks

There is a risk of chemical interaction between the mold and the ceramic.

Carbon ions from the mold can diffuse into the ceramic material through grain boundaries during high-temperature sintering.

This can create defects or alter the material's properties (such as optical performance or electrical conductivity), necessitating a barrier (like graphite paper) or careful control of sintering time.

Making the Right Choice for Your Goal

When designing a hot pressing protocol for Silicon Carbide, how you utilize the graphite mold impacts your final metrics.

- If your primary focus is Maximum Density: Ensure the mold wall thickness is sufficient to withstand axial pressures significantly above 30 MPa to maximize particle packing.

- If your primary focus is Surface Quality: Prioritize the use of high-quality graphite paper liners to prevent diffusion bonding and ensure clean demolding.

- If your primary focus is Cost Efficiency: Operate strictly within a vacuum or inert environment to extend the lifespan of the graphite mold from single-digit uses to dozens of cycles.

Success in hot pressing SiC relies on treating the graphite mold not just as a holder, but as an active participant in the thermal and mechanical history of the part.

Summary Table:

| Function Category | Key Role | Benefit for SiC Ceramics |

|---|---|---|

| Mechanical | Pressure Transmission | Enables >30 MPa axial force for void elimination |

| Thermal | Uniform Heat Distribution | Eliminates thermal gradients and internal stress |

| Shaping | Geometric Containment | Ensures dimensional stability at >2000°C |

| Interface | Surface Protection | Prevents chemical adhesion and micro-oxidation |

| Lifespan | Environmental Resistance | Lasts 30+ cycles in vacuum/inert atmospheres |

Optimize Your SiC Sintering with KINTEK Expertise

High-performance ceramic manufacturing requires more than just high temperatures; it demands precision-engineered tooling and thermal systems. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique material science requirements.

Whether you are aiming for maximum densification or superior surface quality in your Silicon Carbide components, our specialized solutions provide the thermal stability and pressure control you need.

Ready to elevate your lab's capabilities? Contact us today to discuss your custom furnace needs.

References

- Chang Zou, Xingzhong Guo. Microstructure and Properties of Hot Pressing Sintered SiC/Y3Al5O12 Composite Ceramics for Dry Gas Seals. DOI: 10.3390/ma17051182

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Magnesium Extraction and Purification Condensing Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What processes are used for vacuum pressing and preforming of fabrics and fiber materials? Master Uniform Consolidation for Composites

- What role does a laboratory hydraulic press play in forming BCZT powder? Achieve Precise 10mm Green Compacts

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- Why is high temperature control precision essential in a vacuum hot pressing sintering furnace? Ensure Material Density

- How does a vacuum hot pressing sintering furnace contribute to Cu/Ti3SiC2/C/MWCNTs? Achieve High Density & Purity

- Why are Carbon Fiber Reinforced Composite (CFRC) plates used in SPS? Optimize Thermal Stability in Sintering

- What are the size variations available for hot press furnaces? Choose the Right Size for Your Lab or Production Needs

- What is the significant advantage of using a vacuum hot press furnace compared to pressureless sintering for preparing highly dense h-BN ceramics? Achieve Near-Theoretical Density with Mechanical Force