At their core, modern porcelain-fused-to-metal (PFM) dental furnaces are highly versatile thermal processing units designed for a wide array of dental materials, not just traditional metal-ceramics. Their key functionalities include precise, programmable control over temperature cycles, heating rates, holding times, and vacuum levels. This allows labs to execute the specific firing or sintering schedules required for materials ranging from zirconia and lithium disilicate to advanced composite resins.

The term "PFM furnace" is now a misnomer. These devices have evolved into multi-material programmable hubs, enabling dental laboratories to process nearly any modern restorative material with a single, reliable piece of equipment.

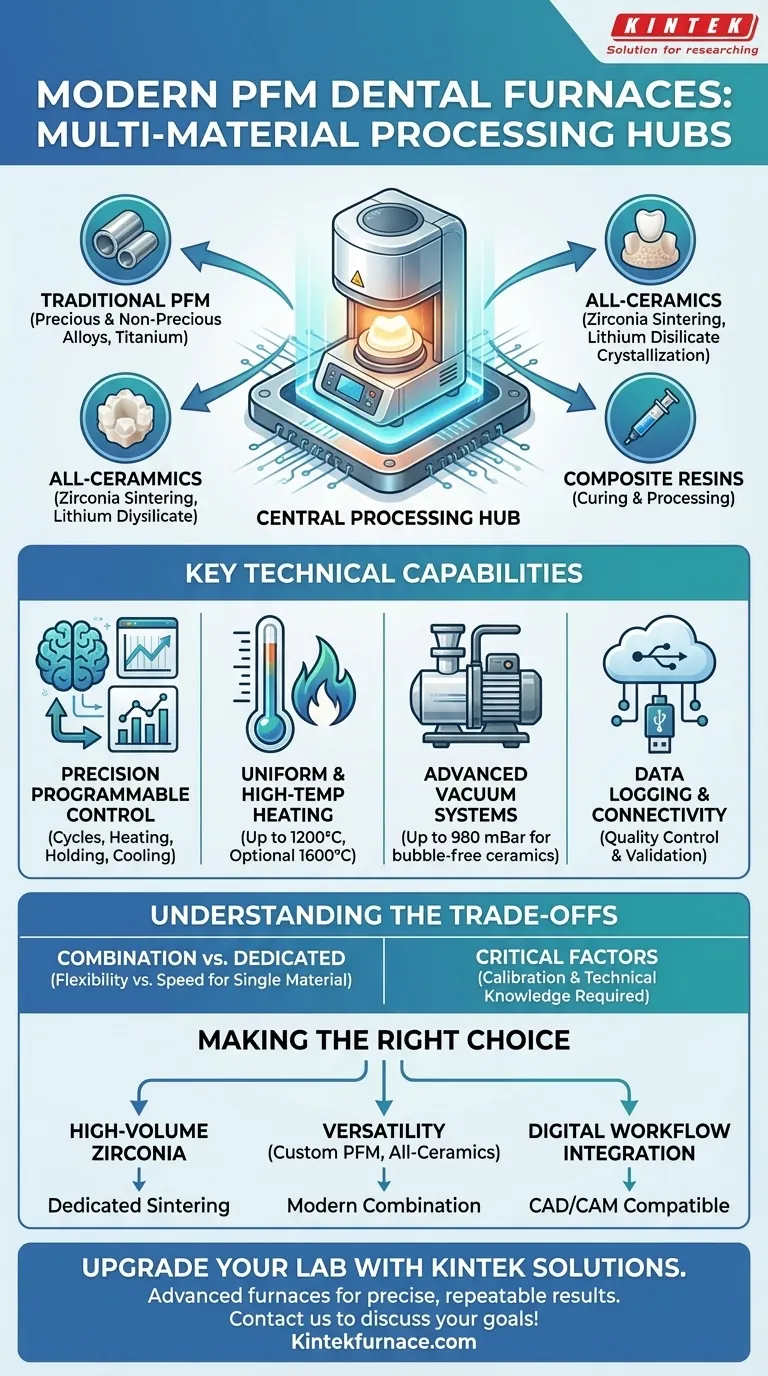

The Furnace as a Central Processing Hub

The modern dental furnace is no longer a single-purpose device. It has become a cornerstone of the lab, providing the controlled environment necessary to achieve the desired physical and aesthetic properties across a spectrum of materials.

Beyond Traditional Metal-Ceramics

While they excel at firing porcelain onto metal frameworks (including precious alloys, non-precious alloys, and titanium), their true value lies in their adaptability. They are engineered as sophisticated, electronically-controlled devices with fully programmable cycles.

Handling All-Ceramics

Modern furnaces are critical for processing popular all-ceramic restorations. They can execute the specific, high-temperature sintering programs required for zirconia and the crystallization cycles needed for materials like lithium disilicate. They can also fire all-ceramic inlays and veneers directly on refractory dies.

Accommodating Composite Resins

The precise temperature control extends to lower ranges, allowing for the curing and processing of advanced composite resins. This programmability ensures that each material receives the exact thermal treatment specified by the manufacturer for optimal strength and polishability.

Key Technical Capabilities

The furnace's versatility is not accidental; it is the result of several key engineering features working in concert to provide total control over the firing environment.

Precision Programmable Control

The brain of the unit is a multi-segment programmable controller, often operated via a color touch screen. This allows technicians to use dozens of built-in programs for common materials or easily create and save custom cycles, adjusting parameters like heating rate, holding time, and cooling mode.

Uniform and High-Temperature Heating

A uniform heating zone is essential for preventing thermal stress and ensuring predictable results. These furnaces can typically reach a maximum temperature of 1200°C, with some models offering optional upgrades to 1600°C to handle even the most demanding materials.

Advanced Vacuum Systems

Creating a vacuum is critical for firing dense, non-porous porcelain. Modern units feature powerful pumps capable of achieving a maximum vacuum of up to 980 mBar, ensuring high-quality, bubble-free ceramic layers.

Data Logging and Connectivity

Features like USB ports and RS 232/485 communication are now standard. This enables the storage and logging of temperature data, which is crucial for quality control, process validation, and remote diagnostics.

Understanding the Trade-offs

While incredibly versatile, these furnaces are not a magic bullet. Understanding their limitations is key to making an informed investment.

"Combination" vs. "Dedicated"

A furnace that does everything may not do one specific thing as fast as a dedicated unit. For a lab with extremely high zirconia production, a dedicated high-speed sintering furnace might still be a more efficient choice for that specific workflow.

The Importance of Calibration

To ensure accuracy across a wide range of temperatures and materials, frequent and precise calibration is non-negotiable. Using a single furnace for different material types also requires strict protocols to avoid cross-contamination that could affect restoration quality.

Reliance on Technical Knowledge

The vast programmability is only as good as the technician's understanding of the materials. Achieving optimal results requires knowledge of the specific firing parameters recommended by each material manufacturer. It is not always a "plug-and-play" process.

Making the Right Choice for Your Goal

The right furnace ultimately depends on your laboratory's primary workload, budget, and future ambitions.

- If your primary focus is high-volume zirconia production: A dedicated sintering furnace may offer superior speed and throughput for that single purpose.

- If your primary focus is versatility for custom PFM, veneers, and all-ceramics: A modern combination furnace provides the essential flexibility to handle diverse, complex cases without investing in multiple machines.

- If your primary focus is integration with a digital CAD/CAM workflow: Prioritize furnaces specifically designed to complement systems like CEREC and inLab for a seamless, validated process.

Ultimately, the most important function of a modern dental furnace is to provide the precise, repeatable control necessary to achieve optimal aesthetics and durability across the full spectrum of restorative materials.

Summary Table:

| Functionality | Key Features | Materials Supported |

|---|---|---|

| Precision Control | Programmable temperature cycles, heating rates, holding times | Zirconia, lithium disilicate, composite resins |

| Heating Capabilities | Uniform heating up to 1200°C (optional 1600°C) | All-ceramics, metal frameworks |

| Vacuum Systems | Up to 980 mBar vacuum for bubble-free ceramics | Porcelain, advanced composites |

| Data and Connectivity | USB, RS 232/485, data logging for quality control | All materials for process validation |

Upgrade your dental lab's capabilities with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces tailored for materials like zirconia, lithium disilicate, and composite resins. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, enhanced by deep customization to meet your unique experimental needs. Achieve precise, repeatable results and boost efficiency—contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab