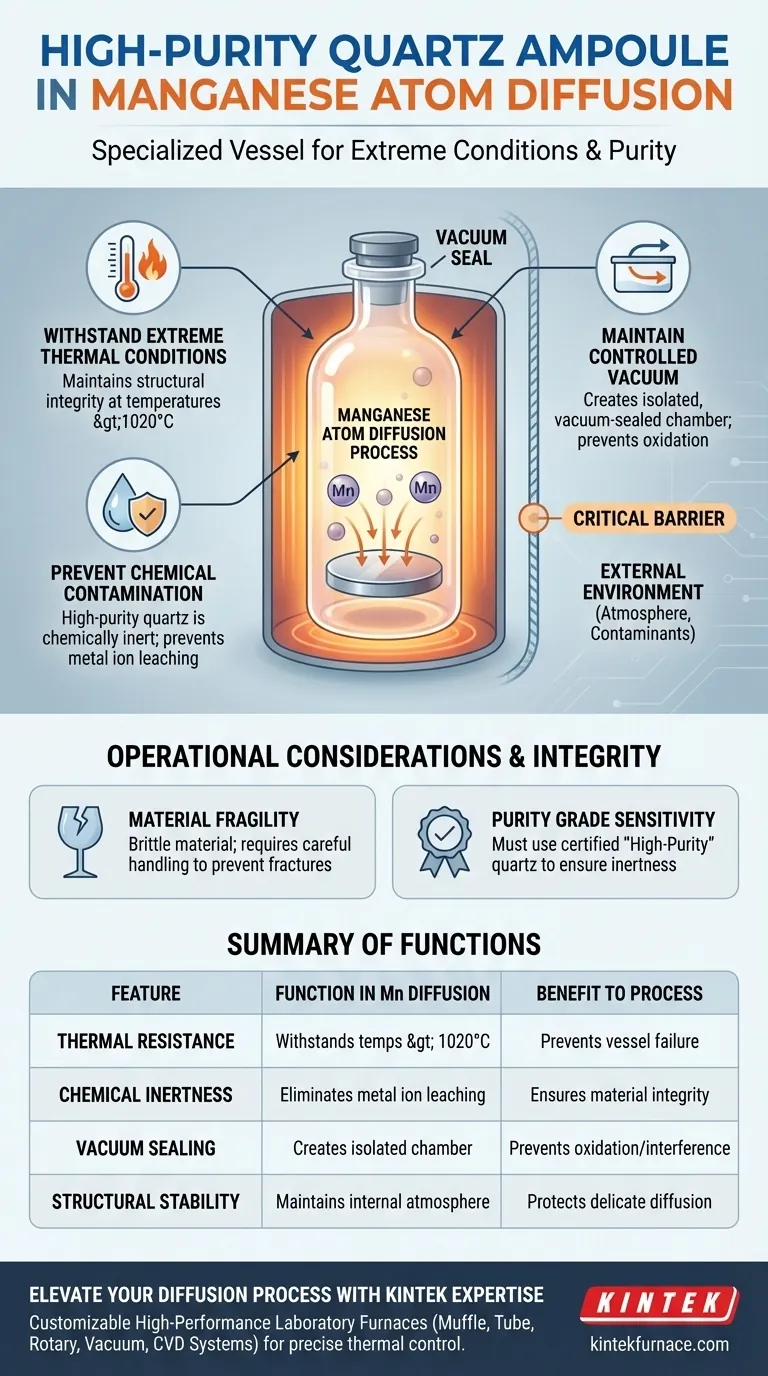

A high-purity quartz ampoule serves as a specialized, contaminant-free reaction vessel designed to withstand extreme thermal conditions. It functions as a vacuum-sealed chamber that isolates the manganese diffusion process, ensuring material integrity at temperatures exceeding 1020°C. Its primary role is to prevent chemical interference while maintaining a closed environment.

The ampoule acts as the critical barrier between the delicate diffusion process and the external environment. By combining extreme thermal resistance with chemical inertness, it prevents metal ion contamination and maintains the vacuum necessary for precise atomic diffusion.

The Critical Functions of the Quartz Vessel

To understand the necessity of the quartz ampoule, one must look at the specific environmental requirements of manganese atom diffusion. The vessel manages three distinct physical challenges simultaneously.

Withstanding Extreme Thermal Conditions

Manganese diffusion is a high-energy process that requires significant heat to initiate atomic movement. The ampoule functions as a robust container capable of maintaining its structural integrity at temperatures exceeding 1020°C.

Standard glass or lower-grade materials would soften or fail under these conditions. The high-purity quartz ensures the reaction zone remains stable throughout the heating cycle.

Preventing Chemical Contamination

In diffusion processes, purity is paramount; even trace impurities can alter the electrical or physical properties of the target material.

The ampoule utilizes the superior chemical inertness of high-purity quartz. This property actively prevents the leaching or introduction of additional metal ion contamination from the vessel walls into the diffusion atmosphere.

Maintaining a Controlled Vacuum

Success depends on a strictly controlled atmosphere. The design of the quartz ampoule allows it to be vacuum sealed prior to heating.

This sealing capability creates a closed, isolated system. It protects the manganese and the target substrate from oxidation or reaction with atmospheric gases during the diffusion process.

Operational Considerations

While high-purity quartz is the standard for this application, it is important to recognize the operational constraints inherent in its use.

Material Fragility

Despite its high thermal resistance, quartz remains a brittle material. It requires careful handling during the loading and sealing phases to prevent micro-fractures that could compromise the vacuum seal under heat.

Purity Grade Sensitivity

Not all quartz is equal. The reference specifically specifies "high-purity" quartz. Using lower-grade quartz substitutes may survive the temperature but fail the inertness requirement, leading to ionic contamination.

Ensuring Process Integrity

When selecting vessels for high-temperature diffusion, focus on the specific needs of your thermal profile and purity standards.

- If your primary focus is Thermal Stability: Ensure the quartz grade selected is rated to maintain structural rigidity well above the 1020°C operational threshold.

- If your primary focus is Contamination Control: Verify the quartz is certified "high-purity" to guarantee the chemical inertness required to block metal ion transfer.

The quartz ampoule is not merely a container; it is an active component of the quality control system in solid-state diffusion.

Summary Table:

| Feature | Function in Manganese Diffusion | Benefit to Process |

|---|---|---|

| Thermal Resistance | Withstands temperatures > 1020°C | Prevents vessel deformation or failure |

| Chemical Inertness | Eliminates metal ion leaching | Ensures high-purity material integrity |

| Vacuum Sealing | Creates an isolated reaction chamber | Prevents oxidation and atmospheric interference |

| Structural Stability | Maintains internal atmosphere | Protects delicate atomic movement patterns |

Elevate Your Diffusion Process with KINTEK Expertise

Precise atomic diffusion requires more than just high-quality vessels; it demands a perfectly controlled thermal environment. KINTEK provides the industry-leading laboratory solutions you need to succeed. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to meet your unique diffusion and sintering requirements.

Don't let contamination or thermal instability compromise your research. Contact KINTEK today to discover how our specialized high-temperature equipment can ensure your process integrity and deliver superior results.

Visual Guide

References

- A. T. Mamadalimov, Makhmudhodzha Isaev. Study of infrared quenching in silicide-silicon-silicide structures. DOI: 10.62476/apr61.55

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is a graphite crucible preferred for SiNQ synthesis? Master Heat Management in Magnesiothermic Reduction

- What necessary conditions does a vacuum chamber provide for vapor deposition? Achieve High-Purity Nanofluid Synthesis

- What factors should be considered when selecting a laboratory furnace? Ensure Optimal Performance and Safety

- How do a brass cap and a cooling element work together? Ensuring Reliable High-Temperature Experimental Seals

- Why use high-performance insulation bricks in radiant tube simulations? Ensure precision and industrial accuracy.

- What role does a molecular pump set play in an electric current-assisted TLP bonding system? Enhance Vacuum Purity

- How are constant temperature water baths and drying ovens utilized to verify bonding quality? Master EN 314-1 Testing

- How do quartz crucibles and quartz cover plates protect the substrate? Optimize TiO2 Nanowire Growth