From a technical standpoint, a vacuum furnace provides significant environmental benefits primarily through its inherent energy efficiency and the complete elimination of harmful process emissions. By operating within a sealed, controlled vacuum, it prevents the release of exhaust gases, byproducts, and contaminants that are common in traditional atmosphere-based furnaces, making it a fundamentally cleaner technology.

The core environmental advantage of a vacuum furnace is not just what it avoids producing (emissions), but the efficiency baked into its design. The vacuum itself is a near-perfect insulator, drastically reducing the energy required for high-temperature processes compared to conventional furnaces.

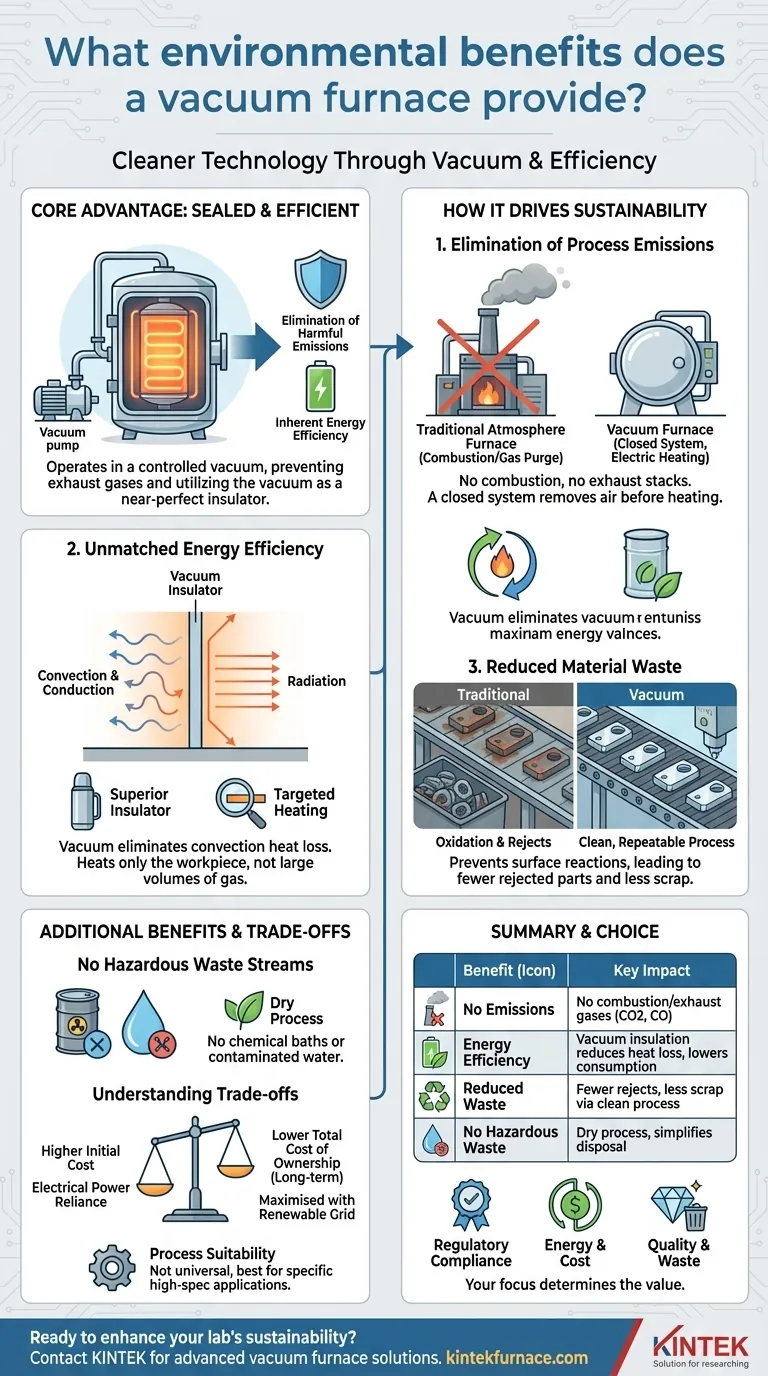

How a Vacuum Environment Drives Sustainability

The environmental benefits of a vacuum furnace are a direct consequence of its core operating principle: removing the atmosphere rather than trying to control it. This creates a cascade of positive effects.

The Elimination of Process Emissions

In a traditional atmosphere furnace, fossil fuels are often burned or protective gases are used and purged, creating byproducts like carbon dioxide, carbon monoxide, and other pollutants.

A vacuum furnace is a closed system. It uses electric heating elements and powerful pumps to remove air and other gases before the heating cycle begins. This means no combustion occurs and no process gases are vented to the atmosphere, eliminating the need for exhaust stacks or pollution control equipment.

Unmatched Energy Efficiency

Vacuum furnaces are exceptionally energy-efficient for two key reasons.

First, the vacuum is a superior insulator. Heat primarily transfers through conduction and convection. By removing the air, you eliminate convection as a path for heat to escape the hot zone. Heat is only lost through radiation, dramatically reducing the energy needed to maintain temperature.

Second, the furnace only heats the workpiece and its fixtures. Atmosphere furnaces waste a significant amount of energy heating a large volume of process gas (like nitrogen or argon) that constantly flows through the chamber. A vacuum furnace bypasses this entirely, focusing energy only where it's needed.

Reduced Material Waste

The clean, inert environment of a vacuum prevents oxidation, decarburization, and other surface reactions that can compromise a part's integrity.

This results in a brighter, cleaner final product with superior metallurgical properties. The process is highly repeatable and controllable, leading to fewer rejected or scrapped parts, which in turn reduces material waste and the environmental footprint associated with rework or remanufacturing.

No Hazardous Waste Streams

Unlike some heat treatment processes that may require chemical baths or produce contaminated wastewater, a vacuum furnace is a dry process.

The system does not generate contaminated water or other hazardous byproducts, simplifying environmental compliance and eliminating the costs and risks associated with treating and disposing of industrial wastewater.

Understanding the Trade-offs

While the benefits are clear, a complete technical assessment requires acknowledging the trade-offs.

Higher Initial Capital Cost

Vacuum furnaces typically represent a higher upfront investment compared to conventional atmosphere furnaces. The environmental and operational savings in energy, gas consumption, and compliance are realized over the furnace's lifespan, contributing to a lower total cost of ownership.

Reliance on Electrical Power

A vacuum furnace's cleanliness is absolute at the point of use. However, its overall environmental impact is tied to the source of the electricity powering it. Its green credentials are maximised when powered by a grid with a high percentage of renewable energy sources.

Process Suitability

Although incredibly versatile, a vacuum furnace is not the universal solution for every thermal process. Certain very high-volume, low-specification applications may find simpler, continuous-belt atmosphere furnaces to be more cost-effective, albeit with a greater environmental impact.

Making the Right Choice for Your Goal

Your specific objectives will determine how you weigh the advantages of a vacuum furnace.

- If your primary focus is regulatory compliance and emissions reduction: A vacuum furnace offers a direct path to eliminating process-related air pollutants, exhaust stacks, and associated treatment costs.

- If your primary focus is energy efficiency and operational cost: The inherent insulating properties of the vacuum and targeted heating lead to significantly lower long-term energy consumption per cycle.

- If your primary focus is product quality and waste reduction: The contamination-free environment minimizes part rejects and material waste, contributing to a leaner, more sustainable manufacturing operation.

Ultimately, the environmental advantages of a vacuum furnace are a direct result of its superior process control and fundamental design efficiency.

Summary Table:

| Environmental Benefit | Key Impact |

|---|---|

| Elimination of Process Emissions | No combustion or exhaust gases released, removing pollutants like CO2 and CO |

| Energy Efficiency | Vacuum acts as superior insulator, reducing heat loss and lowering energy consumption |

| Reduced Material Waste | Prevents oxidation and decarburization, leading to fewer rejected parts and less scrap |

| No Hazardous Waste Streams | Dry process avoids contaminated water and chemical byproducts, simplifying disposal |

Ready to enhance your lab's sustainability with advanced vacuum furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, helping you achieve cleaner, more efficient processes. Contact us today to discuss how our solutions can reduce your environmental impact and improve operational efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment