Changing the diameter of staged combustion nozzles fundamentally alters the aerodynamics and thermal profile of the flame. specifically, reducing the nozzle diameter increases the velocity of the fuel-air jet, resulting in a more intense mixture and an elongated flame structure. This shift physically moves the primary reaction zone further down the radiant tube.

By manipulating the nozzle diameter, you are effectively controlling the flame's length and the location of its peak temperature. Smaller diameters create faster, longer flames that delay the high-temperature reaction, which is the primary mechanism for achieving ultra-low NOx emissions.

The Mechanics of Velocity and Mixing

Increasing Jet Velocity

The most immediate physical effect of reducing the nozzle diameter is a sharp increase in jet velocity.

Forcing the same volume of fuel and air through a smaller opening naturally accelerates the flow.

Intensifying the Mixture

This increased velocity leads to a higher intensity of the air-fuel mixture.

The kinetic energy introduced by the faster jet improves how thoroughly the fuel and oxidizer interact before combustion completes.

Impact on Flame Geometry

Elongating the Flame Shape

A smaller nozzle diameter results in a more elongated flame shape.

Rather than mushrooming out near the burner head, the high-velocity jet pushes the flame structure further into the radiant tube.

Shifting the Reaction Zone

Consequently, the zone of highest temperature does not occur immediately at the nozzle exit.

Instead, the high-temperature reaction zone shifts further downstream. This prevents localized overheating near the burner mounting face and distributes heat energy over a longer distance.

Thermal Profile and Emissions

Optimizing Temperature Gradients

Adjusting the diameter allows you to optimize the temperature gradient along the entire path of the flame.

By stretching the flame, you flatten the temperature spike, avoiding the intense hot spots that damage tubes and generate pollutants.

Achieving Ultra-Low NOx

This optimization is the critical factor in meeting ultra-low NOx emission standards.

By controlling the mixing intensity and delaying the peak temperature release, the system suppresses the thermal conditions required for NOx formation.

Understanding the Trade-offs

Altering Geometric Distribution

It is important to recognize that changing the nozzle diameter significantly alters the geometric distribution of the flame.

While a smaller diameter promotes elongation, it changes where the heat flux is applied to the process.

The Constraint of Tube Design

You are not tuning the burner in a vacuum; the flame geometry must match the physical constraints of the radiant tube.

An optimized gradient for emissions must still provide sufficient heat transfer in the correct zones for your specific process application.

Making the Right Choice for Your Goal

To apply these principles effectively, consider your primary operational objective:

- If your primary focus is Reducing NOx Emissions: Prioritize a smaller nozzle diameter to increase jet velocity, which shifts the high-temperature zone downstream and suppresses pollutant formation.

- If your primary focus is Tube Temperature Uniformity: Adjust the diameter to elongate the flame sufficiently so that the heat release is distributed along the tube length rather than concentrated at the burner head.

Correctly sizing the nozzle turns the physics of combustion into a precise tool for thermal uniformity.

Summary Table:

| Change in Nozzle Diameter | Jet Velocity | Flame Geometry | Peak Temperature Zone | NOx Emissions |

|---|---|---|---|---|

| Decrease (Smaller) | Increases | Elongated / Longer | Shifts further downstream | Significant Reduction |

| Increase (Larger) | Decreases | Wider / Shorter | Closer to burner head | Potential Increase |

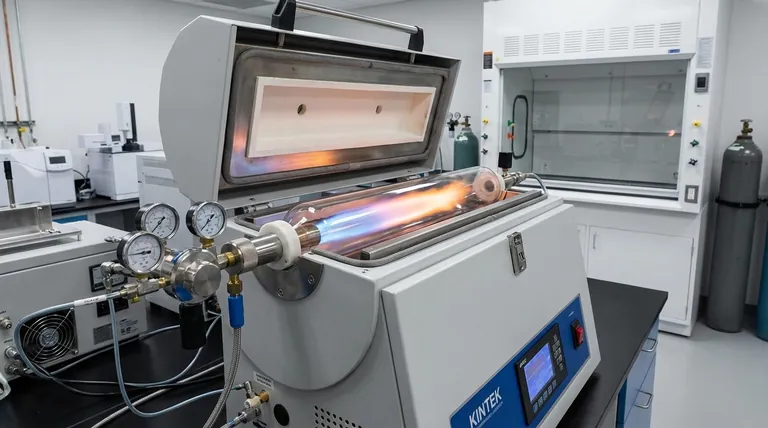

Optimize Your Thermal Performance with KINTEK

Precise combustion control is essential for the longevity of your equipment and the quality of your output. Backed by expert R&D and manufacturing, KINTEK offers a wide range of specialized high-temperature solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which are fully customizable to your unique thermal profile requirements.

Whether you are looking to achieve ultra-low NOx emissions or require a custom-engineered furnace for your laboratory, our technical team is ready to assist. Contact us today to discover how our advanced heating technology can enhance your process efficiency.

Visual Guide

References

- Chien-Cheng Lin, Chien-Hsiung Tsai. Simulation of Staged Combustion Function in Double P-Type Radiant Tubes. DOI: 10.3390/engproc2025092094

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the purpose of K-type thermocouples and multi-channel loggers? Validating Thermal Insulation Performance

- What is the maximum temperature of a heating element? Balancing Material Limits, Atmosphere & Design

- Why Use Three Independent Heating Elements in Oxidation Kinetics? Achieve Precise Zonal Control for Accurate Data

- How is power requirement determined for heaters? Calculate Energy Needs for Efficient Heating

- What are the physical properties of molybdenum disilicide? Discover Its High-Temp Performance

- What temperature range is optimal for the regeneration of the silica layer in MoSi2 heaters? Extend Heater Life with Proper Regeneration

- What are the properties and uses of pure platinum as a heating element? Ideal for High-Temp Precision and Purity

- What are the advantages of silicon carbide heating elements? Achieve High-Temp Reliability and Efficiency