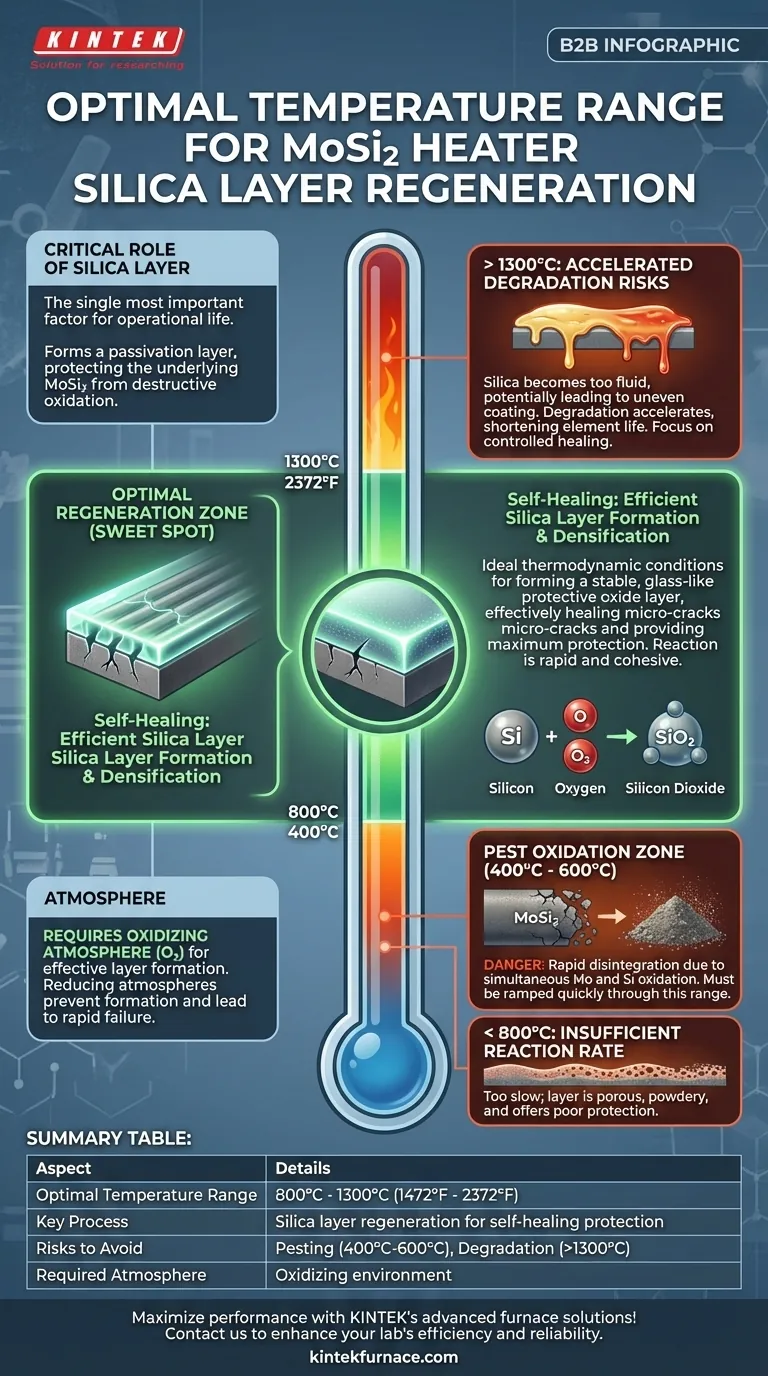

For optimal performance and longevity, the regeneration of the protective silica (SiO2) layer on Molybdenum Disilicide (MoSi2) heating elements should be conducted within a temperature range of 800°C to 1300°C (1472°F to 2372°F). Operating within this window ensures the chemical reaction that forms the protective layer is both efficient and effective, creating a dense, non-porous barrier.

The core principle is not just about heating the element, but about managing a controlled chemical reaction. The 800°C to 1300°C range provides the ideal thermodynamic conditions for the MoSi2 element to "heal" itself by forming a stable, glass-like protective oxide layer.

The Critical Role of the Silica Layer

To understand the importance of this temperature range, you must first understand the function of the silica layer. It is the single most important factor in a MoSi2 element's operational life.

The Self-Healing Mechanism

MoSi2 is an exceptional high-temperature heating material, but it is susceptible to oxidation. When exposed to oxygen at high temperatures, the silicon within the element's matrix migrates to the surface.

There, it reacts with oxygen to form a thin, durable layer of silica (SiO2), which is essentially a form of quartz glass. This passivation layer is what protects the underlying MoSi2 material from further, destructive oxidation.

Why Regeneration is Necessary

This protective layer can be damaged over time by thermal shock from rapid heating/cooling, mechanical stress, or chemical attack. Micro-cracks and spalling can expose the core material.

Regeneration is the process of intentionally operating the element in the correct temperature and atmospheric conditions to re-form and densify this protective silica layer, effectively healing any damage.

Deconstructing the Optimal Temperature Range

The specified range of 800°C to 1300°C is not arbitrary; it is dictated by the chemical kinetics and thermodynamics of silica formation.

Below 800°C: Insufficient Reaction Rate

At temperatures below approximately 800°C, the oxidation reaction that forms the SiO2 layer is too slow to be effective. The resulting layer is often porous and powdery, offering poor protection.

The 800°C - 1300°C Sweet Spot

This is the ideal range for vitrification. The reaction is rapid enough to form a cohesive, self-healing layer.

In this window, the newly formed silica has enough thermal energy to flow and fuse into a dense, non-porous, and amorphous (glassy) coating that seals cracks and provides maximum protection.

Above 1300°C: Accelerated Degradation Risks

While MoSi2 elements can operate at much higher temperatures (up to 1800°C or more depending on the grade), continuous operation at the extreme end of the regeneration range can be counterproductive.

At very high temperatures, the silica can become too fluid, potentially leading to dripping or uneven coating. More importantly, other degradation mechanisms can accelerate, shortening the element's overall life. The goal is controlled healing, not just maximum heat.

Understanding the Pitfalls and Trade-offs

Properly managing MoSi2 elements requires awareness of what can go wrong, especially at lower temperatures.

The Danger of "Pest" Oxidation

The most significant risk at low temperatures is a phenomenon known as pest oxidation or "pesting." This occurs between approximately 400°C and 600°C.

In this range, both molybdenum and silicon oxidize simultaneously, forming a loose, voluminous powder that can cause the element to completely disintegrate. This is why MoSi2 elements must be heated and cooled rapidly through this dangerous temperature zone.

The Need for an Oxidizing Atmosphere

The entire self-healing process is predicated on the availability of oxygen.

If you operate MoSi2 elements in a reducing atmosphere (like hydrogen or cracked ammonia), the protective silica layer cannot form. This will lead to rapid failure unless specialized procedures are followed.

Impact of Thermal Cycling

Elements that are frequently cycled on and off are more prone to micro-cracking due to the stresses of thermal expansion and contraction.

These applications benefit the most from periodic, deliberate "regeneration" runs, where the furnace is held in the 800°C - 1300°C range for a period to allow the protective layer to heal.

How to Apply This to Your Process

Your operational strategy should be based on your specific application and goals for the heating elements.

- If your primary focus is commissioning new elements: Always perform an initial conditioning run by slowly heating the elements and holding them in the 1000°C to 1300°C range for a few hours to form a robust initial protective layer.

- If your primary focus is extending the life of existing elements: Schedule periodic maintenance holds where the furnace operates unloaded in the optimal range to repair any accumulated micro-damage.

- If your primary focus is avoiding catastrophic failure: Ensure your process ramps temperature quickly through the 400°C - 600°C "pesting" zone during both heat-up and cool-down.

By actively managing the health of the protective silica layer, you transform the heating element from a simple consumable into a durable, long-lasting asset.

Summary Table:

| Aspect | Details |

|---|---|

| Optimal Temperature Range | 800°C to 1300°C (1472°F to 2372°F) |

| Key Process | Silica layer regeneration for self-healing protection |

| Risks to Avoid | Pesting oxidation at 400°C-600°C, degradation above 1300°C |

| Required Atmosphere | Oxidizing environment for effective layer formation |

Maximize the performance and lifespan of your MoSi2 heaters with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, helping you achieve optimal regeneration and avoid costly failures. Contact us today to discuss how we can enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs