At its core, a porcelain furnace provides dental technicians with precise control over three key aesthetic properties: shade, translucency, and surface texture. This control is the mechanism that allows for the creation of crowns, veneers, and bridges that are virtually indistinguishable from a patient's natural teeth.

The true value of a porcelain furnace lies not just in its ability to fire ceramics, but in its capacity to transform a standard restoration into a custom work of art. It bridges the gap between functional repair and lifelike aesthetics, directly impacting patient satisfaction and clinical success.

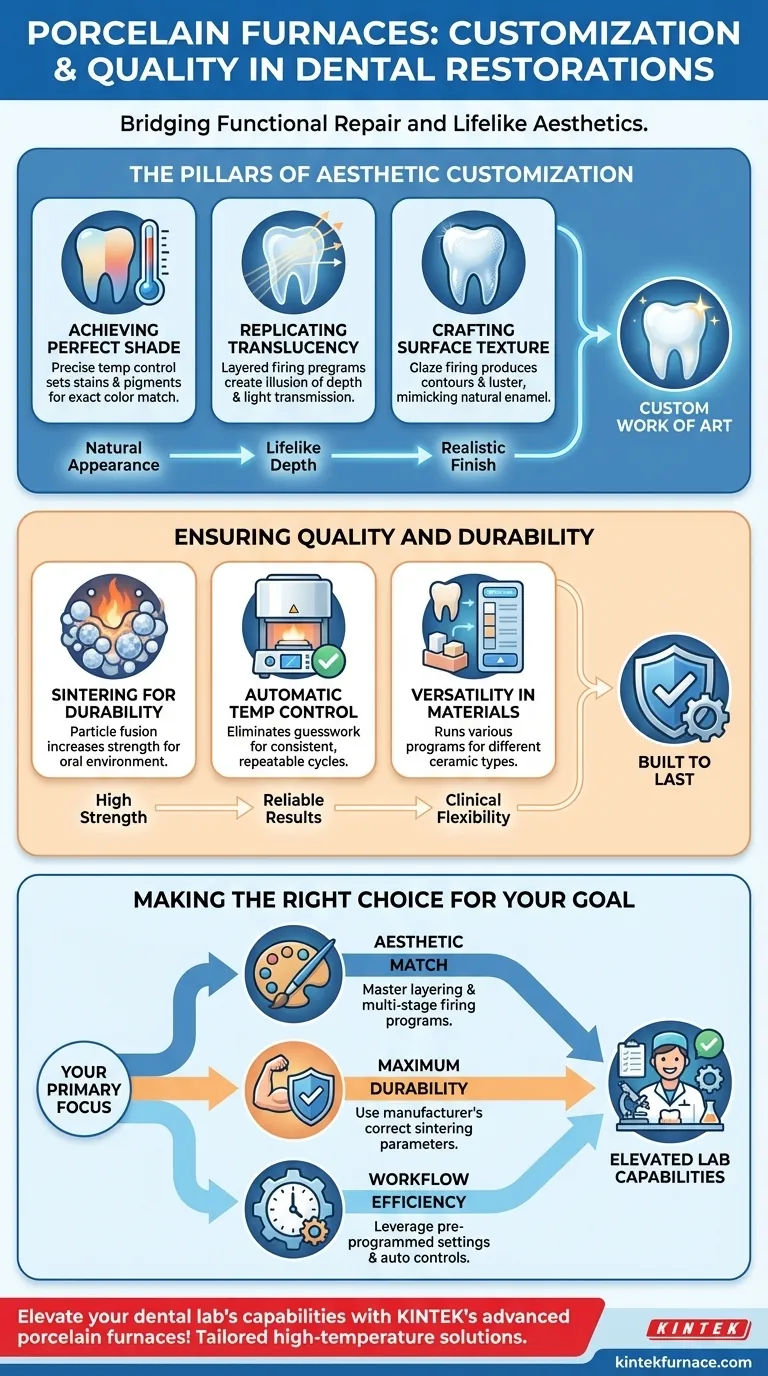

The Pillars of Aesthetic Customization

A porcelain furnace's primary function is to execute highly controlled heating cycles. This precision enables the dental technician to manipulate the ceramic material to achieve a seamless, natural look.

Achieving the Perfect Shade

The most fundamental customization is matching the color, or shade, of the restoration to the adjacent teeth. The furnace's precise temperature control is critical for setting the external stains and internal pigments applied by the technician, ensuring the final shade is exactly as intended.

Replicating Natural Translucency

Natural teeth are not opaque; they have a degree of translucency that allows light to pass through the enamel. A furnace allows technicians to build up restorations in layers and use specific firing programs to achieve this same illusion of depth, preventing the restoration from looking flat or artificial.

Crafting Lifelike Surface Texture

The final firing, known as the glaze firing, creates the restoration's surface texture and luster. A skilled technician uses the furnace to produce a surface that mimics the subtle contours and gloss of natural tooth enamel, ensuring it reflects light in the same way as the surrounding dentition.

How the Furnace Ensures Quality and Durability

The aesthetic results are only possible because of the furnace's underlying technical capabilities. These features ensure that customization is both repeatable and built to last.

The Sintering Process for Durability

The furnace's most critical function is sintering, a process where ceramic particles are heated until they fuse into a solid, dense mass. This dramatically increases the restoration's strength and durability, making it capable of withstanding the demanding conditions of the oral environment.

Automatic Temperature Control for Consistency

Modern furnaces feature automatic temperature regulation. This eliminates guesswork and ensures that every firing cycle is identical, leading to highly consistent results in shade and translucency. This precision is the foundation of a reliable and efficient workflow.

Versatility in Material Processing

Different clinical situations call for different ceramic materials. A key advantage of a high-quality furnace is its versatility to run programs for various types of dental ceramics. This gives the practitioner the flexibility to choose the ideal material for any given case, whether the priority is strength or aesthetics.

Making the Right Choice for Your Goal

The way you leverage your furnace's capabilities depends entirely on the primary objective for the restoration.

- If your primary focus is a perfect aesthetic match: Master the art of layering ceramics and utilize precise, multi-stage firing programs to control shade and translucency.

- If your primary focus is maximum durability: Ensure you are using the correct, manufacturer-recommended sintering parameters for your chosen material to achieve full densification and strength.

- If your primary focus is workflow efficiency: Leverage the furnace's pre-programmed settings and automatic temperature controls to produce consistent, high-quality results with minimal manual intervention.

Ultimately, a porcelain furnace is the instrument that empowers dental professionals to elevate their craft from simple restoration to true anatomical art.

Summary Table:

| Customization Aspect | Key Function | Outcome |

|---|---|---|

| Shade Control | Precise temperature setting for stains and pigments | Exact color match to natural teeth |

| Translucency | Layered firing programs for light transmission | Illusion of depth and natural appearance |

| Surface Texture | Glaze firing for contour and luster | Mimics enamel's light reflection and feel |

| Durability | Sintering process for particle fusion | High strength and long-lasting restorations |

| Consistency | Automatic temperature regulation | Repeatable, reliable aesthetic results |

| Versatility | Programs for various ceramic materials | Flexibility for different clinical needs |

Elevate your dental lab's capabilities with KINTEK's advanced porcelain furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to precisely meet your unique experimental and production requirements. Achieve superior aesthetic and durable restorations—contact us today to discuss how we can enhance your workflow and results!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What should routine inspections of dental furnaces include? Ensure Consistent, High-Quality Dental Restorations

- What is the use of porcelain in dentistry? Achieve Lifelike, Durable Dental Restorations

- What is the step-by-step process for making porcelain dental restorations? Master Precision and Aesthetics

- What is the main purpose of a sintering furnace in dentistry? Transform Zirconia into Strong Dental Restorations

- What are some recent innovations in dental lab equipment furnaces? Boost Efficiency with Smart Automation