The Muffle furnace provides a stable, precisely controlled high-temperature environment essential for the effective solution treatment of Ti–Mo–Fe alloys. Specifically, it enables the alloy to be heated to and maintained at 1100°C for a duration of one hour, a critical threshold required to alter the material's microstructure.

The Muffle furnace acts as a precision thermal anchor, ensuring the complete dissolution of brittle TiFe phases to prepare the microstructure for a successful transformation into a single beta-phase during quenching.

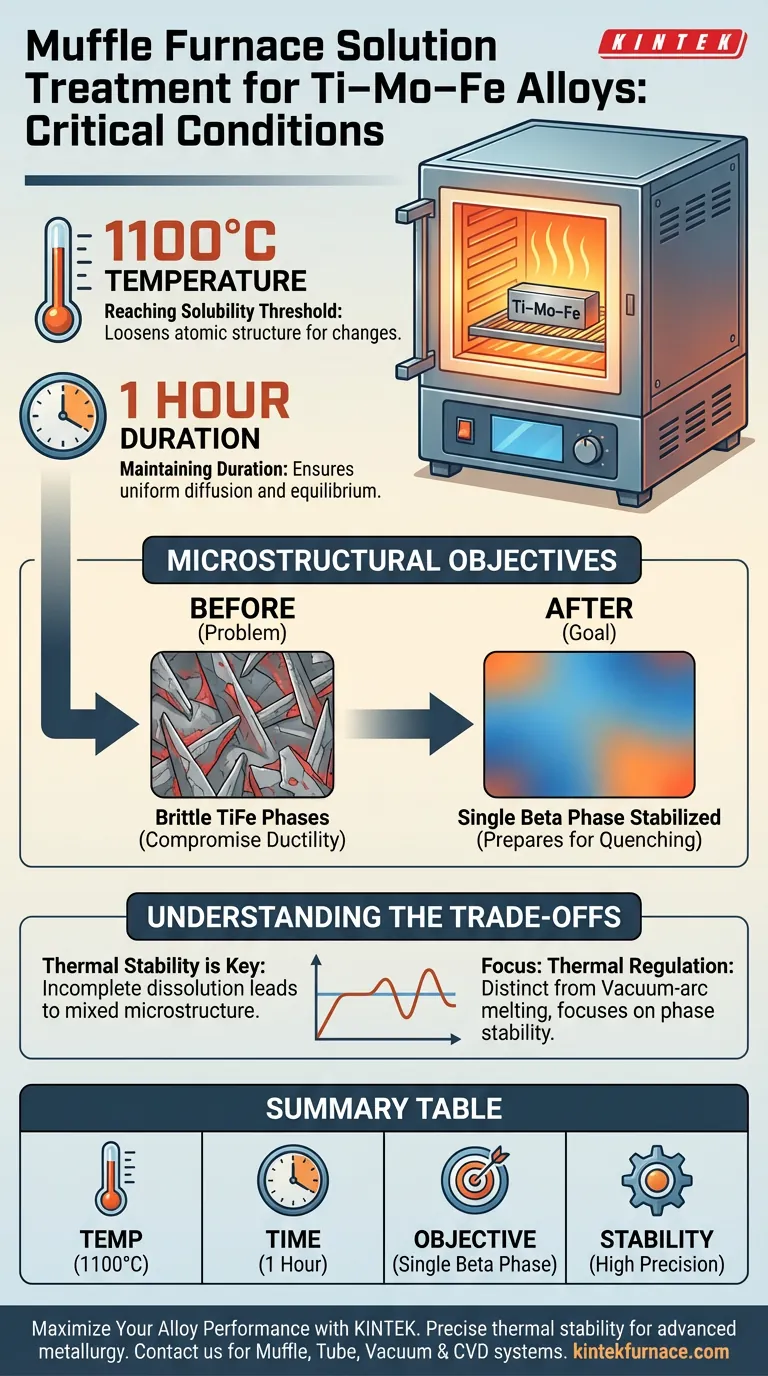

The Critical Thermal Parameters

Reaching the Solubility Threshold

For Ti–Mo–Fe alloys, the solution treatment is not merely about heating; it is about reaching a specific phase-transformation threshold.

The Muffle furnace must be capable of reaching 1100°C with high accuracy.

At this specific temperature, the atomic structure of the alloy loosens sufficiently to allow for significant microstructural changes.

The Necessity of Duration

Reaching temperature is insufficient; the alloy must soak at this heat level to reach equilibrium.

The furnace must maintain this 1100°C temperature for one hour.

This duration provides the necessary time window for diffusion to occur, ensuring the internal changes are uniform throughout the sample volume.

Microstructural Objectives

Dissolving Brittle Intermetallics

The primary enemy of ductility in this alloy system is the presence of TiFe intermetallic phases.

These phases are inherently brittle and compromise the mechanical integrity of the final product.

The high-temperature environment provided by the Muffle furnace facilitates the dissolution of these brittle phases back into the matrix.

Stabilizing the Beta Phase

The ultimate goal of this heat treatment is to prepare the alloy for the subsequent quenching process.

By holding the alloy at 1100°C, the furnace stabilizes the beta phase.

This thermal preparation creates the necessary conditions for a single beta-phase microstructure to be retained after the material is rapidly cooled.

Understanding the Trade-offs

Thermal Stability vs. Microstructural Inconsistency

The defining characteristic of a high-quality Muffle furnace in this context is thermal stability.

If the furnace cannot maintain a precise 1100°C—fluctuating even slightly—the dissolution of TiFe phases may be incomplete.

Incomplete dissolution results in a mixed microstructure after quenching, failing to achieve the desired single beta-phase properties.

The Role of Atmosphere Control

While the primary focus of a Muffle furnace is thermal consistency, it is distinct from Vacuum-arc melting furnaces used for synthesis.

Vacuum furnaces are used during melting to prevent oxidation and ensure chemical purity.

However, during solution treatment in a Muffle furnace, the focus shifts strictly to thermal regulation to manipulate phase stability, though operators must always be mindful of titanium's reactivity at high temperatures.

Making the Right Choice for Your Goal

When setting up a treatment protocol for Ti–Mo–Fe alloys, consider the following:

- If your primary focus is mechanical ductility: Ensure the furnace can hold 1100°C without fluctuation to fully dissolve brittle TiFe phases.

- If your primary focus is microstructural uniformity: Prioritize the duration of the soak (one hour) to guarantee the beta phase is stabilized throughout the entire sample cross-section.

Success in processing Ti–Mo–Fe alloys depends entirely on the Muffle furnace's ability to maintain the precise thermal conditions required for phase transformation.

Summary Table:

| Parameter | Target Value | Microstructural Impact |

|---|---|---|

| Solution Temperature | 1100°C | Dissolves brittle TiFe intermetallic phases |

| Holding Time | 1 Hour | Ensures uniform diffusion and phase equilibrium |

| Phase Objective | Single Beta Phase | Prepares alloy for successful quenching |

| Required Stability | High Precision | Prevents microstructural inconsistency |

Maximize Your Alloy Performance with KINTEK

Precise phase transformation requires unwavering thermal stability. KINTEK provides industry-leading Muffle, Tube, Vacuum, and CVD systems designed to meet the rigorous demands of advanced metallurgy.

Whether you are refining Ti–Mo–Fe alloys or developing next-generation materials, our expert-backed R&D and manufacturing ensure your lab is equipped with high-temp furnaces customizable to your exact specifications.

Ready to achieve superior microstructural uniformity?

Contact KINTEK today to discuss your thermal processing needs

Visual Guide

References

- Nthabiseng Moshokoa, Maje Phasha. Influence of intermetallic phase (TiFe) on the microstructural evolution and mechanical properties of as-cast and quenched Ti–Mo–Fe alloys. DOI: 10.1038/s41598-024-60894-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the common heating elements used in muffle furnaces and their corresponding temperature ranges? Choose the Right Element for Your Lab

- What role does a laboratory oven play in lignin nanofiber stabilization? Unlock Precision Thermal Cross-linking

- What key functions does a muffle furnace perform during the industrial analysis of coal samples? Optimize Proximate Analysis

- How is temperature controlled in a box type electric furnace? Master Precise Heat Regulation for Your Lab

- Why is an industrial high-temperature furnace required for chemical activation? Achieve 700°C Precision for Carbon

- How does the price of a muffle furnace vary? Find the Perfect Fit for Your Lab's Budget

- Why is a high-precision muffle furnace required for the 500 °C calcination treatment during catalyst preparation?

- What materials are used in the construction of the muffle furnace? Discover the Key Components for High-Temp Performance