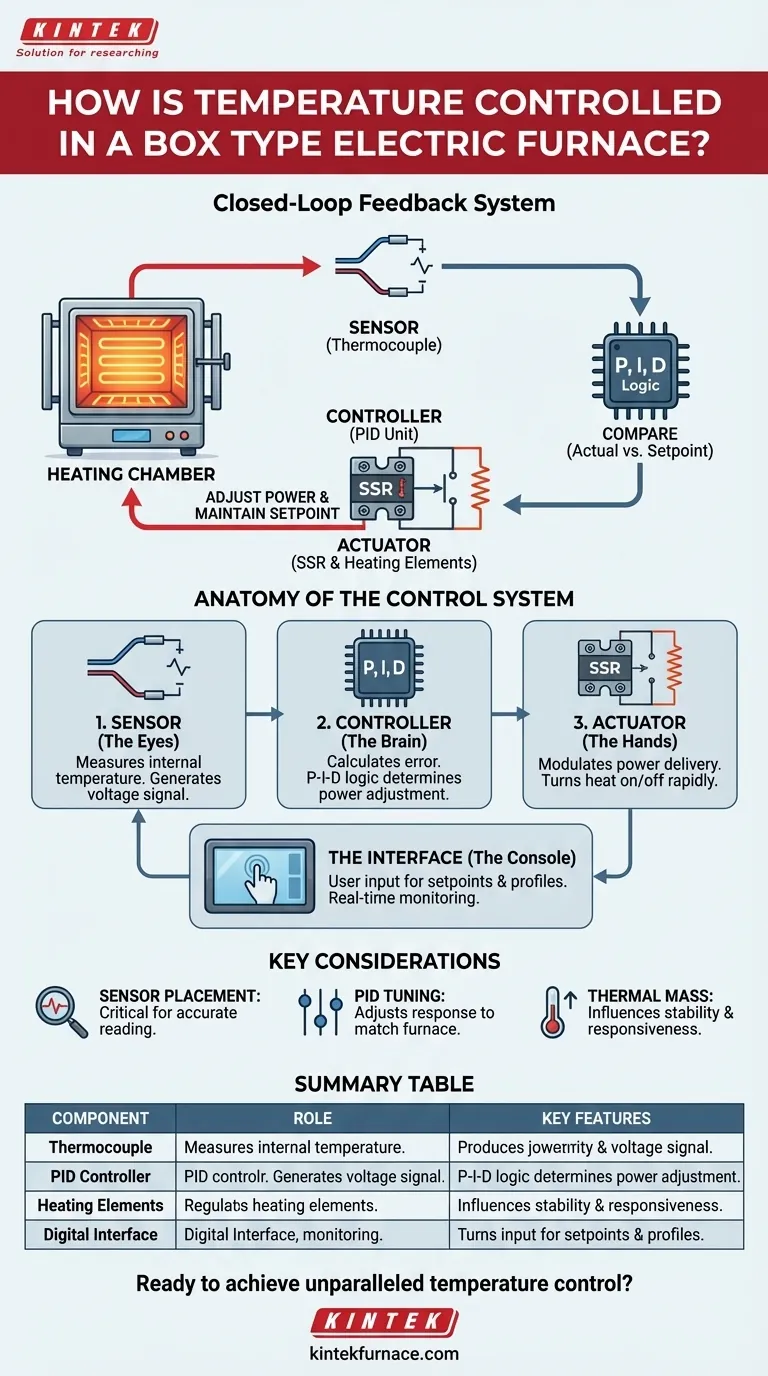

In essence, temperature in a box-type electric furnace is controlled by a closed-loop feedback system. A temperature sensor, typically a thermocouple, constantly measures the internal temperature. This reading is sent to a digital controller which compares it to your desired temperature (the setpoint) and then intelligently adjusts the electrical power delivered to the heating elements to maintain that setpoint with high precision.

The core principle is not simply heating, but continuous and intelligent regulation. The system operates in a constant loop of measuring the current temperature, comparing it to the target, and adjusting the heating power to minimize any difference, thereby ensuring stability and preventing temperature overshoots.

The Anatomy of the Control System

To truly understand how a furnace maintains a stable temperature, you must look at its three primary components working in unison: the sensor, the controller, and the heating elements.

The Sensor (The Eyes): The Thermocouple

A thermocouple is the system's nerve ending inside the heating chamber. It is a simple yet robust sensor made from two different metals joined at one end.

This junction produces a tiny voltage that changes predictably with temperature. The controller reads this voltage to get a precise, real-time measurement of the conditions inside the furnace.

The Controller (The Brain): The PID Unit

The controller is the brain of the operation. Modern furnaces almost universally use a PID (Proportional-Integral-Derivative) controller. This isn't just an on/off switch; it's a sophisticated algorithm.

The controller receives the temperature data from the thermocouple and constantly calculates the "error"—the difference between the actual temperature and the user's setpoint. It then uses the PID logic to decide exactly how much power to apply.

- Proportional (P): Reacts to the current error. A large difference means a large power adjustment.

- Integral (I): Corrects for past error, eliminating small, steady-state deviations that the P-term alone might ignore.

- Derivative (D): Predicts future error by looking at the rate of temperature change, preventing overshoot as the temperature approaches the setpoint.

The Actuator (The Hands): Heating Elements and Relays

The controller's decision is carried out by adjusting power to the heating elements.

This is typically done using a Solid State Relay (SSR). The PID controller sends a precise signal to the SSR, which then modulates the flow of high voltage electricity to the resistive heating elements, turning heat on and off rapidly to achieve an average power level.

The Interface (The Console): Touch Screen or Panel

This is the component you interact with. A digital control panel or touch screen allows you to input your desired temperature setpoint and program heating profiles (e.g., ramp up to 800°C, hold for two hours, then cool down).

Understanding the Trade-offs and Key Considerations

An effective control system is more than just good components; it's about how they are integrated and tuned for the furnace's physical characteristics.

The Importance of Sensor Placement

The location of the thermocouple is critical. If it's placed too close to a heating element or the door, it will not provide an accurate reading of the temperature throughout the main chamber. For high-precision work, multiple thermocouples may be used to ensure uniformity.

The Nuance of PID Tuning

A PID controller must be "tuned" to the specific furnace. This process adjusts the P, I, and D values to match the furnace's thermal mass, insulation, and heating power. A poorly tuned system can lead to temperature oscillations (hunting) or a very slow response time.

The Role of Thermal Mass

The physical construction of the furnace—its insulation and the mass of its internal components—heavily influences temperature stability. A furnace with high thermal mass will heat and cool more slowly, which can make it inherently more stable but less responsive to rapid setpoint changes.

Making the Right Choice for Your Goal

The ideal temperature control configuration depends entirely on your application's requirements for precision, speed, and ease of use.

- If your primary focus is high-precision processing (e.g., materials science, semiconductor annealing): You need a furnace with a well-tuned PID controller and ensure the thermocouple is certified and optimally placed for your workload.

- If your primary focus is efficiency and throughput (e.g., production heat treating): Prioritize a system with a powerful and responsive controller that minimizes ramp-up times and avoids overshooting, which wastes energy and time.

- If your primary focus is general laboratory use and reliability (e.g., ashing, drying): A standard system with a modern touch-screen interface and pre-programmed profiles will provide the best balance of performance and usability.

By understanding this control loop, you transform the furnace from a simple hot box into a precise and predictable technical instrument.

Summary Table:

| Component | Role in Temperature Control | Key Features |

|---|---|---|

| Thermocouple | Measures internal temperature | Produces voltage proportional to temperature, placed for accuracy |

| PID Controller | Compares and adjusts power | Uses Proportional, Integral, Derivative logic to minimize error |

| Heating Elements | Generate heat based on signals | Controlled via Solid State Relay for precise power modulation |

| Digital Interface | User input for setpoints | Allows programming of heating profiles and real-time monitoring |

Ready to achieve unparalleled temperature control in your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're in materials science, production heat treating, or general lab work, we can help you optimize efficiency and precision. Contact us today to discuss how our furnaces can elevate your processes!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- How does a laboratory high-temperature box furnace assist in evaluating concrete fire resistance? | KINTEK