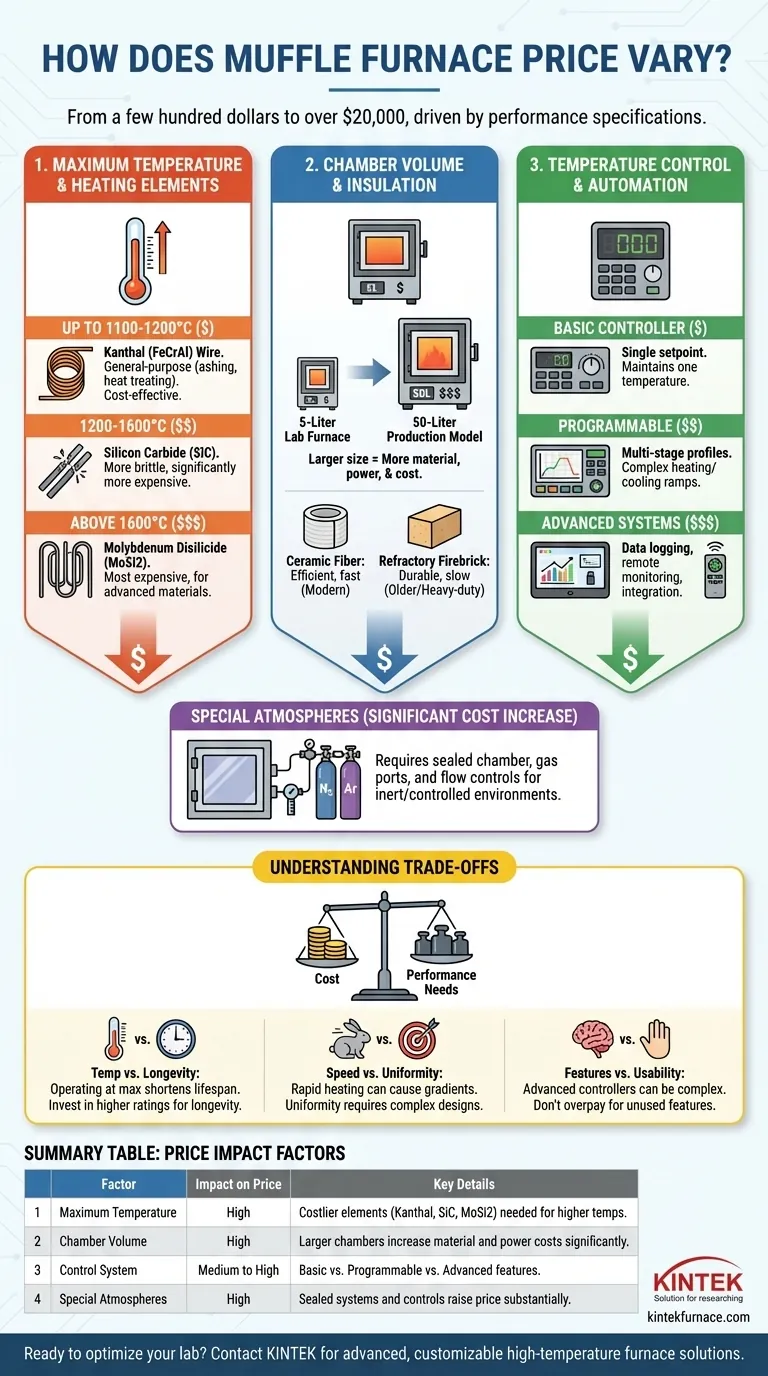

The price of a muffle furnace is not a single number but a wide spectrum, ranging from a few hundred dollars for small, basic models to well over $20,000 for large, specialized industrial units. This variation is driven directly by three core factors: the maximum achievable temperature, the internal chamber volume, and the sophistication of its control system. Understanding how these elements contribute to the final cost is the key to making a sound investment.

The final price of a muffle furnace is a direct reflection of its engineered capabilities. To find the right value, you must first define your specific operational needs for temperature, capacity, and process control, as this will prevent you from either overpaying for features you don't need or under-investing in a tool that can't perform its core task.

Core Factors Driving Muffle Furnace Price

A muffle furnace is a system of interconnected components, and the specifications of each part contribute to the final cost. The most significant price drivers are tied directly to performance metrics.

Maximum Temperature and Heating Elements

The single greatest factor in furnace cost is its maximum operating temperature. Higher temperatures demand more robust and expensive materials for both the heating elements and the insulation.

- Up to 1100-1200°C (2012-2192°F): Most standard and economical furnaces operate in this range, using Kanthal (FeCrAl) wire heating elements. These are reliable and cost-effective for general-purpose applications like ashing, heat treating, and burn-off.

- 1200-1600°C (2192-2912°F): Reaching these temperatures requires silicon carbide (SiC) heating elements. These are more brittle and significantly more expensive, which is reflected in the furnace's price tag.

- Above 1600°C (2912°F+): High-end research and industrial furnaces use molybdenum disilicide (MoSi2) elements. These are the most expensive but are necessary for applications involving advanced ceramics and materials science.

Chamber Volume and Insulation

The size of the heating chamber directly impacts material costs and the power required to maintain temperature.

- Size: A larger chamber requires more insulation material, more powerful heating elements, and a more robust power supply, all of which increase cost. A 5-liter laboratory furnace will be an order of magnitude cheaper than a 50-liter production model with the same temperature rating.

- Insulation Type: Modern furnaces often use lightweight vacuum-formed ceramic fiber insulation. It offers excellent thermal efficiency and allows for faster heat-up and cool-down times. Older or more heavy-duty designs may use refractory firebrick, which is durable but less efficient and slower to respond.

Temperature Control and Automation

The "brains" of the furnace are a key differentiator. The level of precision, automation, and data logging you require will heavily influence the price.

- Basic Controllers: The most affordable furnaces feature a simple digital controller that maintains a single target temperature (a setpoint).

- Programmable Controllers: Mid-range and professional models use multi-stage programmable controllers. These allow you to create complex heating profiles with multiple ramps (rate of temperature change) and soaks (holding at a temperature for a set time).

- Advanced Systems: The most expensive units offer controllers with features like data logging via USB or Ethernet, remote control and monitoring, and integration with safety interlocks and other lab systems.

Special Atmospheres

Standard muffle furnaces operate with a normal air atmosphere. If your process requires a controlled or inert atmosphere (e.g., nitrogen or argon to prevent oxidation), the cost increases substantially. This requires a fully sealed chamber, gas inlet and outlet ports, and flow control systems, adding significant engineering complexity and expense.

Understanding the Trade-offs

Choosing a furnace involves balancing performance needs with your budget. The cheapest option is rarely the best value if it fails to meet your requirements or wears out prematurely.

High Temperature vs. Longevity

Continuously operating a furnace at its absolute maximum rated temperature will drastically shorten the lifespan of its heating elements. A furnace rated for 1200°C will last much longer if it is typically operated at 1050°C. If your process requires consistent 1150°C operation, investing in a furnace rated for 1300°C or higher is a wise long-term decision.

Speed vs. Uniformity

Rapid heating rates can be convenient, but they can also create temperature gradients within the chamber, meaning the center might be hotter than the corners. Furnaces engineered for high temperature uniformity often have more complex heating element arrangements and sophisticated controls, which increases their cost but ensures consistent results for sensitive processes.

Features vs. Usability

An advanced, multi-stage programmable controller is powerful but can introduce complexity. For a simple, repeated process like ashing a sample at one temperature, a basic, reliable controller is often more efficient and less prone to user error. Don't pay for programming capabilities you will never use.

Selecting the Right Furnace for Your Budget

To choose wisely, start by defining your non-negotiable process requirements. Then, find the furnace that meets those needs most economically.

- If your primary focus is hobby work or occasional, low-temperature use: A small, benchtop furnace with a single setpoint controller and a max temperature of 1100°C offers the best value.

- If your primary focus is standard laboratory testing (e.g., ashing, materials analysis): Prioritize a mid-range furnace (up to 1200°C) from a reputable brand with a reliable multi-stage programmable controller and excellent temperature uniformity.

- If your primary focus is advanced research or production with sensitive materials: Your budget must accommodate a furnace with the necessary temperature rating (>1200°C) and any specialized atmosphere or data logging capabilities your process demands.

By clearly defining your operational needs first, you can confidently select a muffle furnace that provides the necessary performance without overextending your budget.

Summary Table:

| Factor | Impact on Price | Key Details |

|---|---|---|

| Maximum Temperature | High | Higher temps require costlier heating elements (e.g., Kanthal, SiC, MoSi2). |

| Chamber Volume | High | Larger chambers increase material and power costs significantly. |

| Control System | Medium to High | Basic controllers are affordable; programmable/advanced systems add expense. |

| Special Atmospheres | High | Inert gas systems require sealed chambers and controls, raising price. |

Ready to optimize your lab with the right muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization capabilities to ensure precise performance for your experiments. Don't settle for less—contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control