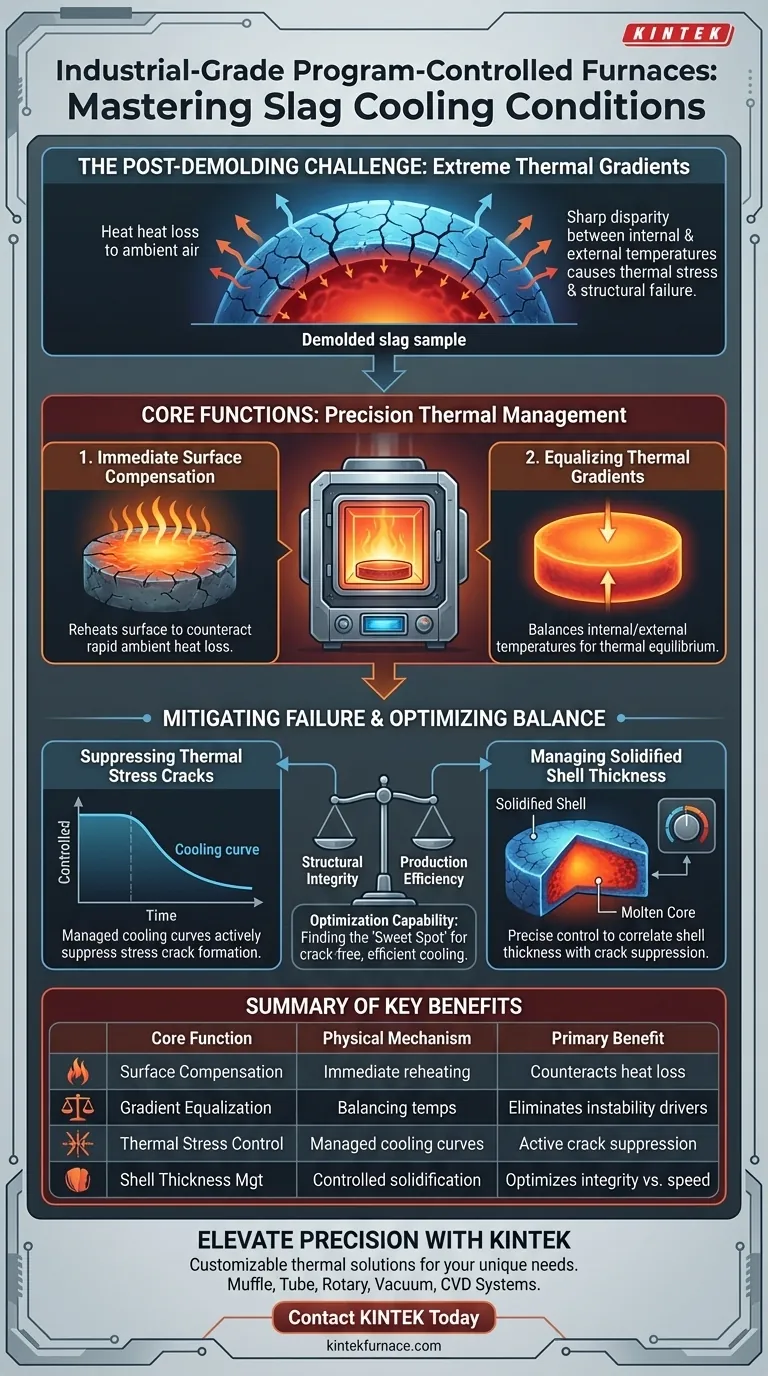

Industrial-grade program-controlled furnaces function primarily as high-precision thermal management systems designed to stabilize slag immediately after the demolding process. Their core capabilities center on precise temperature compensation and controlled slow cooling, specifically reheating the material's surface to neutralize the sharp disparity between internal and external temperatures.

By intervening effectively post-demolding, these furnaces eliminate extreme temperature gradients that cause structural failure. They allow operators to isolate the relationship between solidified shell thickness and thermal stress, ensuring that crack suppression does not come at the cost of production efficiency.

Precision Thermal Management

Immediate Surface Compensation

Once slag is removed from a mold, its surface is exposed to cooler ambient air while the core remains molten or extremely hot.

The program-controlled furnace intervenes immediately to reheat the surface of the sample. This action counteracts the rapid heat loss that typically occurs the moment the material is demolded.

Equalizing Thermal Gradients

The fundamental physical goal of this equipment is thermal equilibrium.

By applying targeted heat to the exterior, the system helps equalize the internal and external temperatures. This prevents the formation of steep temperature gradients that are the primary drivers of material instability.

Mitigating Structural Failure

Suppressing Thermal Stress Cracks

When the outside of a material cools much faster than the inside, tension builds up, resulting in thermal stress.

These furnaces provide a controlled thermal environment designed to eliminate these stresses. By managing the cooling curve, the system actively suppresses the formation of thermal stress cracks that would otherwise ruin the sample.

Managing Solidified Shell Thickness

A critical aspect of slag management is controlling the thickness of the solidified shell—the outer crust of the material.

This technology allows researchers and engineers to study exactly how shell thickness correlates with crack formation. It provides the control necessary to manipulate this variable precisely.

Understanding the Operational Balance

The Efficiency Trade-off

In traditional cooling scenarios, preventing cracks often requires significantly slowing down the process, which hurts production throughput.

The critical trade-off here is balancing structural integrity against production efficiency.

Optimization Capability

This furnace technology is designed to solve that trade-off.

It enables the study of cooling conditions that suppress cracks without sacrificing efficiency. The goal is to find the "sweet spot" where the cooling is slow enough to prevent defects but fast enough to maintain industrial viability.

Making the Right Choice for Your Goal

To maximize the utility of an industrial-grade program-controlled furnace, align its functions with your specific operational targets:

- If your primary focus is Quality Assurance: Leverage the precise temperature compensation to minimize the delta between surface and core temperatures immediately post-demolding to prevent thermal shock.

- If your primary focus is Process Efficiency: Use the controlled slow cooling features to determine the minimum solidified shell thickness required to suppress cracks, allowing for the fastest possible safe cooling rate.

These systems transform cooling from a passive waiting period into an active, value-adding process.

Summary Table:

| Core Function | Physical Mechanism | Primary Benefit |

|---|---|---|

| Surface Compensation | Immediate reheating post-demolding | Counteracts rapid ambient heat loss |

| Gradient Equalization | Balancing internal/external temps | Eliminates drivers of material instability |

| Thermal Stress Control | Managed cooling curves | Active suppression of stress cracks |

| Shell Thickness Mgt | Controlled shell solidification | Optimizes the balance of integrity vs. speed |

Elevate Your Slag Management Precision with KINTEK

Don't let thermal stress compromise your material integrity or production throughput. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to meet the rigorous demands of industrial slag research and production.

Backed by expert R&D and precision manufacturing, our lab high-temp furnaces are fully customizable to help you achieve the perfect cooling curve for your unique needs.

Ready to optimize your thermal management? Contact KINTEK today to discover how our expert systems can enhance your lab's efficiency and product quality.

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the key features of laboratory vacuum furnaces? Unlock Pure, Controlled High-Temp Processing

- What key technologies are used in the development of multi-chamber continuous vacuum furnaces? Boost Throughput with Advanced Automation

- What is the temperature of a vacuum brazing furnace? Precision Heat for Flawless Metal Joining

- What additional capabilities do laboratory vacuum furnaces offer besides high-temperature heating? Unlock Precision Control for Advanced Materials

- What role does a vacuum annealing furnace play in NCG synthesis? Precision Carbonization for Nanomaterials

- What are the limitations of high vacuum furnaces? Understand Costs, Time, and Material Challenges

- What role does vacuum annealing play in preventing material oxidation? Ensure Purity with Oxygen-Free Heat Treatment

- What are the benefits of using vacuum and controlled environments in sintering furnaces? Achieve Superior Material Quality and Efficiency