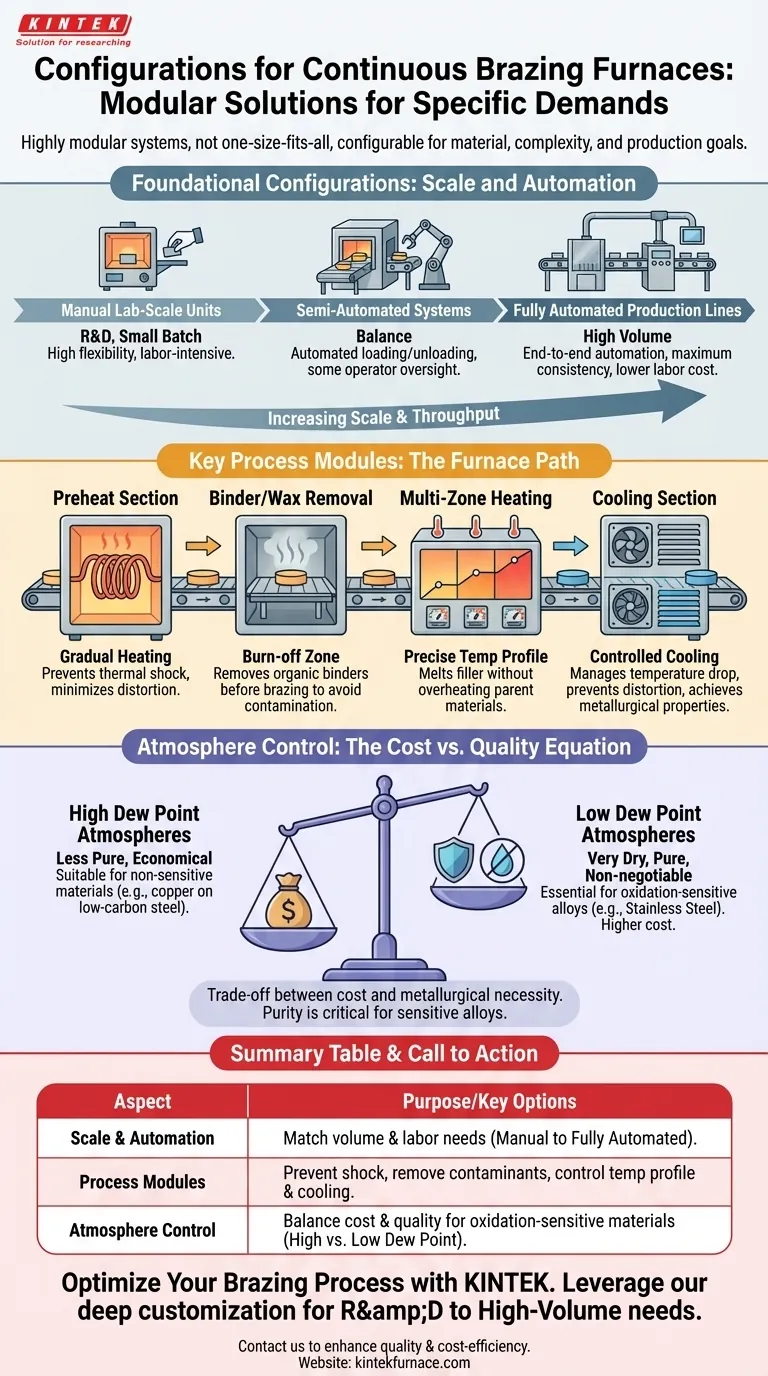

Continuous brazing furnaces are not one-size-fits-all systems; they are highly modular and can be configured to meet specific production demands. Configurations range from manually loaded laboratory units for research and development to fully automated, high-volume production lines. Key optional modules include preheat sections, binder or wax removal sections, multi-zone heating controls, and systems for precise atmospheric control like low or high dew point.

The optimal furnace configuration is not determined by the number of features, but by a clear understanding of your specific materials, part complexity, and production goals. Choosing the right modules is a strategic decision that directly impacts brazing quality, throughput, and operational cost.

Foundational Configurations: Scale and Automation

The first decision point is the overall scale and level of automation required for your operation. This choice sets the foundation for all other modules.

Manual Lab-Scale Units

These are the simplest configurations, often designed for research, process development, or very small-batch production. Parts are manually loaded onto and unloaded from the furnace belt. This approach offers maximum flexibility for testing different parameters but is labor-intensive and not suited for high volume.

Semi-Automated Systems

For growing production needs, semi-automated systems offer a balance. They may incorporate automated loading or unloading stations, but still require operator oversight. These systems improve consistency and throughput compared to manual units without the full capital investment of a fully automated line.

Fully Automated Production Lines

Designed for high-volume manufacturing, these are complete, integrated systems. They handle parts from start to finish, including loading, progressing through each furnace zone, and unloading. Automation ensures maximum process consistency, reduces labor costs, and provides a highly repeatable outcome, which is critical for quality control in mass production.

Key Process Modules and Their Purpose

Beyond the level of automation, specialized sections can be added to the furnace to solve specific manufacturing challenges. Each module serves a distinct purpose in achieving a perfect braze joint.

The Preheat Section

A preheat section gradually raises the temperature of the parts before they enter the high-heat brazing zone. This is critical for preventing thermal shock, especially for complex assemblies, large parts, or when joining dissimilar materials with different expansion rates. A slow, controlled preheat minimizes part distortion and stress.

The Binder or Wax Removal Section

Brazing pastes and some pre-forms contain organic binders or waxes that must be removed before the part reaches brazing temperature. A dedicated binder removal section (often called a "burn-off" zone) operates at a lower temperature to vaporize these compounds cleanly. Without it, binders can contaminate the joint, leading to voids, porosity, and a failed braze.

Multi-Zone Heating Control

The core brazing section is rarely a single, uniform heat source. It is typically divided into multiple, independently-controlled zones. This allows you to create a precise temperature profile—ramping up, holding at a peak temperature, and beginning the cooling cycle. This level of control is essential for melting the filler metal without overheating or damaging the parent materials.

The Cooling Section

Just as important as heating, the cooling process must also be controlled. A cooling section, which can be a simple fan-cooled tunnel or a more complex water-jacketed chamber, lowers the part's temperature at a managed rate. This prevents part distortion and helps achieve the desired final metallurgical properties of the material.

Understanding the Trade-offs: Atmosphere Control

The furnace's atmosphere is what prevents oxidation and allows the braze alloy to flow. The purity of this atmosphere, measured by its dew point, is one of the most critical—and often most costly—configuration choices.

High Dew Point Atmospheres

A higher dew point indicates more moisture (water vapor) in the atmosphere. These less-pure atmospheres are suitable and more economical for brazing materials that are not sensitive to oxidation, such as copper brazing of low-carbon steel.

Low Dew Point Atmospheres

A low dew point signifies a very dry, pure atmosphere. This is non-negotiable for brazing materials that oxidize easily, such as stainless steel, or alloys containing chromium, aluminum, or titanium. Achieving and maintaining a low dew point requires a more sophisticated, well-sealed furnace and a high-purity gas supply, increasing both initial and operational costs.

The Cost vs. Quality Equation

Choosing the right atmosphere能力 is a direct trade-off between cost and metallurgical necessity. Attempting to braze stainless steel in a high dew point furnace will result in poor joint quality and failure. Conversely, investing in a low dew point system for simple copper brazing is an unnecessary expense.

Making the Right Choice for Your Goal

Your furnace configuration should be a direct reflection of your manufacturing requirements. Use these points as a guide to prioritize your needs.

- If your primary focus is R&D or small-batch production: A flexible, manual lab-scale unit is你的 best starting point.

- If your primary focus is brazing parts assembled with paste: A furnace with a dedicated binder removal section is essential for joint integrity.

- If your primary focus is high-volume, consistent output: Invest in a fully automated system to maximize throughput and repeatability.

- If your primary focus is brazing stainless steel or other sensitive alloys: Prioritize a furnace system capable of achieving and maintaining a low dew point atmosphere.

By breaking down the furnace into这些 functional modules, you can make a strategic investment tailored precisely to your operational needs.

Summary Table:

| Configuration Aspect | Key Options | Purpose |

|---|---|---|

| Scale and Automation | Manual Lab-Scale, Semi-Automated, Fully Automated | Match production volume and labor needs |

| Process Modules | Preheat, Binder Removal, Multi-Zone Heating, Cooling | Prevent thermal shock, remove contaminants, control temperature, manage cooling |

| Atmosphere Control | High Dew Point, Low Dew Point | Balance cost and quality for oxidation-sensitive materials |

Ready to optimize your brazing process with a tailored furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we can precisely meet your unique experimental and production requirements, whether for R&D, small-batch, or high-volume applications. Contact us today to discuss how our solutions can enhance your brazing quality, throughput, and cost-efficiency!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results

- How do rotary tube furnaces contribute to material science and chemical engineering? Unlock Precision in Material Processing

- What are the key advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency for Your Materials

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits