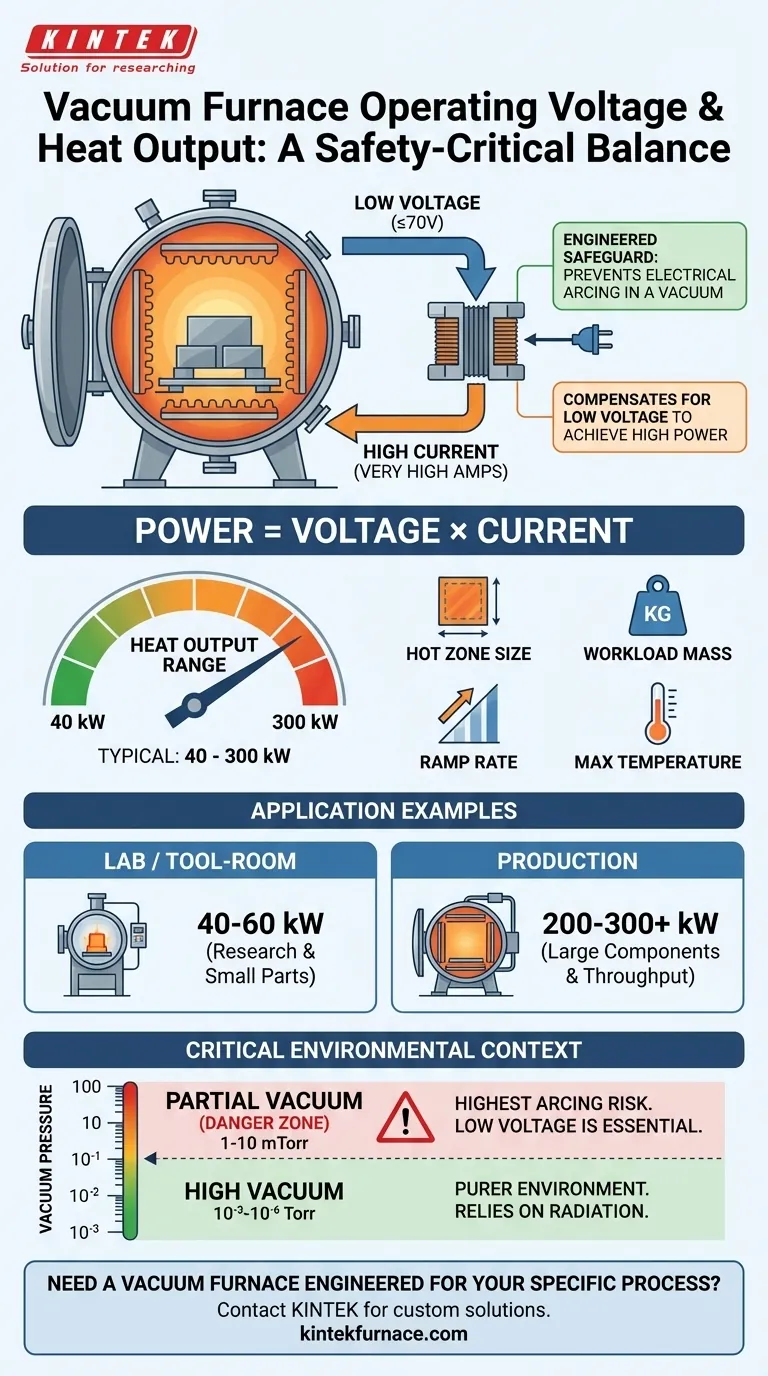

To put it directly, vacuum furnace heating systems are designed around a critical safety principle: they operate at low voltages, typically 70 volts or less, to prevent electrical arcing in a vacuum. To compensate for the low voltage, they use very high current to achieve a total heat output that commonly ranges from 40 to 300 kW.

The core takeaway is that a vacuum furnace's electrical system is a deliberate engineering solution. The low-voltage, high-power design is not a limitation but a fundamental requirement to safely generate immense heat in an environment where high voltage would create catastrophic electrical arcs.

The Core Principle: Why Low Voltage is Non-Negotiable

Understanding the relationship between voltage and the vacuum environment is key to understanding the entire design philosophy of these furnaces. It's fundamentally different from heating in normal atmosphere.

The Physics of Vacuum Arcing

A common misconception is that a vacuum is a perfect electrical insulator. In reality, a partial vacuum can conduct electricity more easily than air at atmospheric pressure.

As air is removed from a chamber, the mean free path between remaining molecules increases. This allows electrons to accelerate to very high energies before colliding with a molecule, making it easier to start a plasma arc at a much lower voltage than would be required in open air.

Low Voltage as an Engineered Safeguard

To prevent this, heating elements are powered by custom transformers that step down standard line voltage to a much safer level, almost always below 70V.

This low voltage potential is insufficient to initiate an arc across the vacuum gaps inside the furnace, ensuring operational stability and protecting the equipment and the workload.

Achieving High Power with High Current

The laws of physics dictate that Power = Voltage × Current. To generate the massive heat required for industrial processes (40-300 kW) at such a low voltage, the system must use extremely high amperage.

This is why vacuum furnace power supplies are such robust, heavy-duty components. They are designed to safely manage and deliver hundreds or even thousands of amps to the heating elements.

Understanding the Heat Output Range (40-300 kW)

The specific power rating of a furnace is determined by the thermal demands of its intended application. A higher kilowatt rating provides more "thermal horsepower."

Factors Influencing Power Requirements

Several key factors determine the necessary heat output:

- Hot Zone Size: A larger furnace volume requires more power to heat.

- Workload Mass: A heavy or dense workload acts as a significant heat sink, demanding more energy to reach temperature.

- Ramp Rate: Achieving a target temperature quickly requires a much higher kW rating than a slow, gradual heating process.

- Maximum Temperature: Higher operating temperatures naturally demand more power to achieve and maintain.

Matching Power to the Application

A small furnace for laboratory research or tool-room heat treating might only require 40-60 kW.

In contrast, a large production furnace used for annealing or brazing massive components will often be in the 200-300 kW range, or even higher, to handle large loads and meet production schedules.

Pitfalls and Environmental Context

The electrical design is directly tied to the vacuum environment it operates in. The level of vacuum has a profound impact on performance and safety.

The "Partial Vacuum" Danger Zone

The highest risk of arcing does not occur at a deep, high-quality vacuum (like 10⁻⁵ Torr) or at atmospheric pressure. The danger is highest in the "rough" or "medium" vacuum range that all furnaces must pass through during pump-down.

This transitional state is where the pressure is ideal for initiating an arc. The low-voltage design ensures the system remains safe even when passing through this critical pressure window.

Impact of Different Vacuum Levels

While a medium vacuum (1 to 10 mTorr) is sufficient for many heat treatments, more sensitive processes like brazing or sintering require a high vacuum (10⁻³ to 10⁻⁶ Torr).

A high vacuum provides a purer environment, but its excellent insulating properties also mean heat transfer relies almost entirely on radiation. The heating system must be designed to radiate heat effectively and uniformly in this environment.

Making the Right Choice for Your Application

When evaluating a vacuum furnace, understanding these specifications helps you align the equipment with your primary operational goal.

- If your primary focus is process safety and reliability: Prioritize systems with a proven, robust, low-voltage power supply specifically designed to eliminate arcing across all operating pressures.

- If your primary focus is production throughput: Ensure the furnace's kW rating is sufficient to heat your maximum workload mass to temperature within your required cycle time.

- If your primary focus is high-purity processes: Match the heating element design and power controls to the required high-vacuum level to ensure thermal uniformity and prevent contamination.

Ultimately, viewing these specifications not as separate numbers but as an integrated system is the key to selecting a furnace that is safe, reliable, and perfectly suited to its task.

Summary Table:

| Specification | Typical Range | Key Rationale |

|---|---|---|

| Operating Voltage | 70 Volts or less | Prevents dangerous electrical arcing in a vacuum environment. |

| Heat Output (Power) | 40 to 300 kW | Provides the thermal energy required for industrial processes like brazing and annealing. |

| Current | Very High | Compensates for low voltage to achieve high power (Power = Voltage × Current). |

Need a Vacuum Furnace Engineered for Your Specific Process?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions. Our expertise in vacuum furnace technology ensures your system is not only safe and reliable but also precisely matched to your thermal requirements—whether you need a compact 40 kW lab furnace or a powerful 300 kW production unit.

Our product line, including Muffle, Tube, Rotary Furnaces, and specialized Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities. We design to meet your unique needs for hot zone size, ramp rates, maximum temperature, and vacuum level.

Contact KINTEL today to discuss how our custom vacuum furnace solutions can enhance your process safety, throughput, and purity.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity