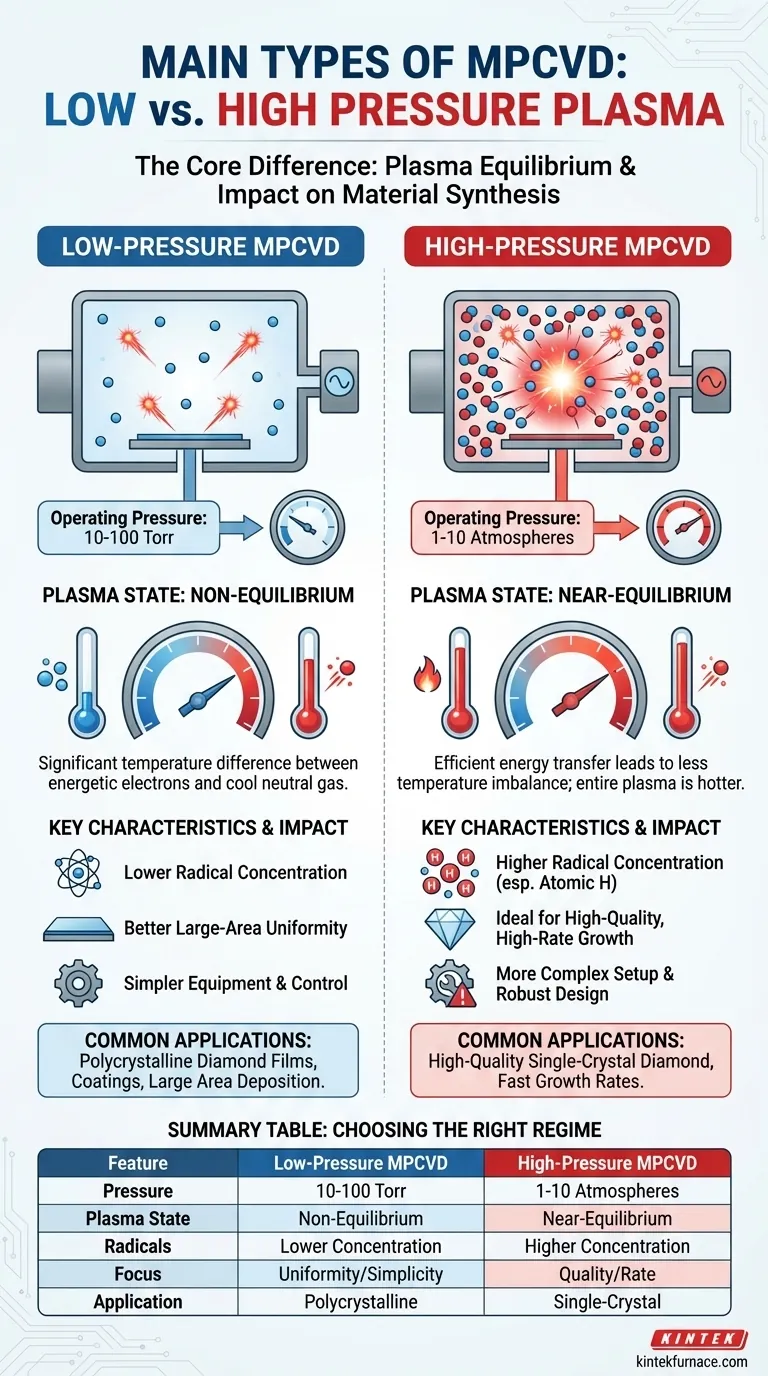

At its core, Microwave Plasma Chemical Vapor Deposition (MPCVD) is categorized into two primary regimes based on operating pressure and the resulting plasma state. The two main types are low-pressure plasma MPCVD, which typically operates between 10-100 Torr, and high-pressure plasma MPCVD, which operates at much higher pressures, often from 1 atmosphere up to 10 atmospheres.

The distinction between low and high-pressure MPCVD is not just about the pressure gauge reading; it's about fundamentally altering the plasma's chemistry. The choice determines the balance between energetic electrons and the gas temperature, which directly controls the concentration of the reactive species critical for material synthesis.

The Defining Factor: Plasma Equilibrium

The gas pressure inside the reactor, combined with microwave power, dictates whether the plasma is in a state of thermal equilibrium. This is the most important difference between the two regimes.

Low-Pressure MPCVD: The Non-Equilibrium State

In a low-pressure environment, gas molecules are far apart. This creates a significant temperature difference between the highly energetic, microwave-heated electrons and the much cooler neutral gas species.

Think of it as a room filled with a few fast-moving sparks (electrons) that rarely collide with the slow-moving air molecules (neutral gas). The sparks are hot, but the room's overall temperature remains low.

This non-equilibrium state results in a lower concentration of the atomic radicals, like atomic hydrogen, that are often desired for high-purity deposition.

High-Pressure MPCVD: The Near-Equilibrium State

At high pressures, molecules are packed closely together. The energetic electrons collide frequently with neutral gas particles, efficiently transferring their energy.

This leads to less temperature imbalance between electrons and the gas. The entire plasma becomes hotter and moves closer to a state of local thermal equilibrium.

The critical advantage of this state is that the high collision rate and energy density create a much higher concentration of atomic hydrogen and other radicals, which are the primary drivers for high-quality diamond growth.

How Pressure Impacts the Growth Process

For applications like lab-grown diamond, the concentration of specific chemical species in the plasma is paramount. Pressure is the knob that tunes this concentration.

The Critical Role of Atomic Hydrogen

In diamond synthesis, atomic hydrogen (H) is the most important species. It performs two essential functions.

First, it selectively etches any non-diamond carbon, like graphite, that might otherwise form on the growth surface, ensuring high purity.

Second, it stabilizes the diamond surface, allowing carbon atoms from the source gas (like methane) to incorporate correctly into the diamond lattice.

High-Pressure's Advantage: A Radical-Rich Environment

High-pressure MPCVD excels at dissociating molecular hydrogen (H₂) into the atomic hydrogen (H) needed for high-quality growth.

The intense, near-equilibrium plasma is simply a more efficient "factory" for producing the radicals that drive the desired chemical reactions, enabling both high purity and high growth rates.

Understanding the Trade-offs

Choosing a pressure regime is not just about maximizing radical concentration. It involves practical considerations and trade-offs in process control and equipment.

Process Stability and Uniformity

Low-pressure plasmas are generally more diffuse and can more easily fill a large volume uniformly. This can make them easier to control when depositing films over a large area.

High-pressure plasmas are often more constricted and intense, appearing as a small, bright "ball." Managing the stability and uniformity of this plasma ball can be more challenging.

Equipment and Complexity

Operating at pressures up to 10 atmospheres requires a significantly more robust reactor chamber design to ensure safety and performance.

The control systems and power delivery for high-pressure systems are also typically more complex than their low-pressure counterparts.

Growth Rate vs. Application

While high-pressure MPCVD is the standard for high-rate, high-quality single-crystal diamond, low-pressure systems are valuable for other applications.

They are used in depositing polycrystalline diamond films or other materials where a different plasma chemistry or lower substrate temperature is desirable.

Making the Right Choice for Your Goal

The optimal pressure regime is entirely dependent on the material you intend to grow and your primary objectives.

- If your primary focus is maximizing single-crystal diamond quality and growth rate: High-pressure MPCVD is the industry standard because it generates the necessary high concentration of atomic hydrogen.

- If your primary focus is large-area film uniformity or process simplicity: Low-pressure MPCVD may offer a more stable and controllable window, particularly for polycrystalline films or coatings.

- If your primary focus is research into novel plasma chemistries: Both regimes are indispensable tools, as the choice depends entirely on the specific energetic conditions you need to create.

Ultimately, understanding this fundamental pressure-plasma relationship empowers you to select the correct tool and conditions to achieve your specific material synthesis goals.

Summary Table:

| Type | Operating Pressure | Plasma State | Key Characteristics |

|---|---|---|---|

| Low-Pressure MPCVD | 10-100 Torr | Non-Equilibrium | Lower radical concentration, better for large-area uniformity, simpler equipment |

| High-Pressure MPCVD | 1-10 atmospheres | Near-Equilibrium | Higher radical concentration, ideal for high-quality diamond growth, more complex setup |

Struggling to choose the right MPCVD system for your diamond synthesis or material research? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether for high-purity diamond growth or uniform film deposition. Contact us today to discuss how our tailored MPCVD solutions can enhance your lab's efficiency and results!

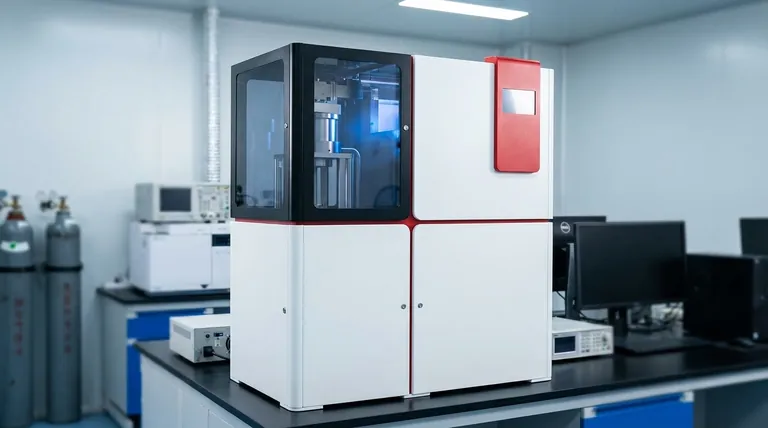

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- Why is the temperature control system important in MPCVD equipment? Ensure Precise Diamond Growth and Process Stability

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth

- Why is keeping maintenance records important for MPCVD equipment? Ensure Reliability and Quality in Crystal Growth

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics