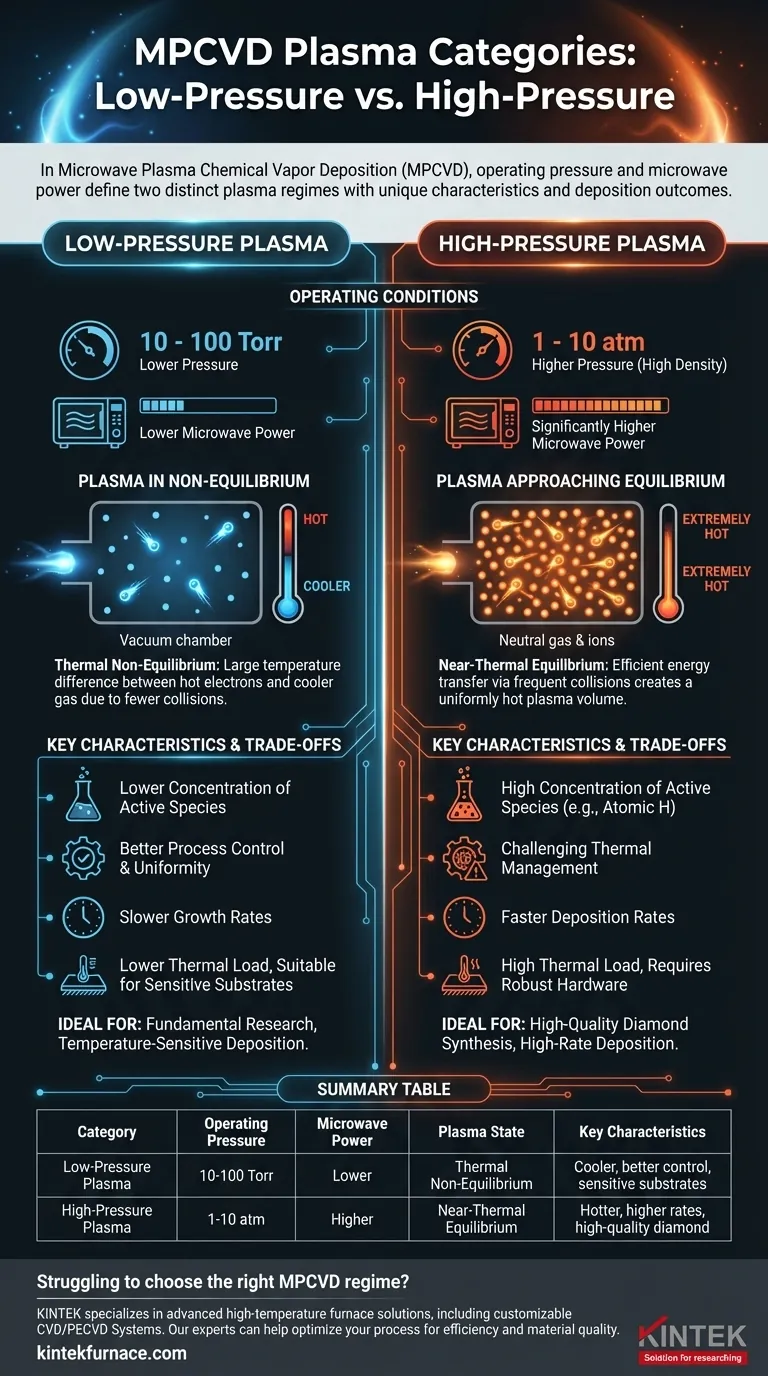

In Microwave Plasma Chemical Vapor Deposition (MPCVD), the plasma is broadly categorized into two distinct regimes defined by operating gas pressure and microwave power: low-pressure plasma and high-pressure plasma. This distinction is critical as it determines the fundamental nature of the plasma, its chemical reactivity, and its suitability for different deposition processes.

The choice between low-pressure and high-pressure MPCVD is a strategic decision that dictates the plasma's thermal equilibrium and chemical composition. This directly impacts material growth rates, quality, and the overall efficiency of the deposition process.

Understanding Low-Pressure Plasma MPCVD

Low-pressure MPCVD represents the more traditional and widely studied regime. It operates under conditions that create a specific type of plasma with distinct characteristics.

Operating Conditions

Systems in this category typically operate at pressures between 10 and 100 Torr. Sustaining a stable plasma at these lower pressures generally requires less microwave power compared to the high-pressure alternative.

Plasma in Non-Equilibrium

The defining feature of low-pressure plasma is its state of thermal non-equilibrium. In this state, there is a large temperature difference between the highly energetic, "hot" electrons and the much "cooler" neutral gas species and ions.

The electrons absorb energy efficiently from the microwave field but, due to the low pressure and fewer collisions, they do not transfer this energy effectively to the heavier particles.

Understanding High-Pressure Plasma MPCVD

High-pressure MPCVD is a more intensive regime, pushing the plasma into a state that is more chemically reactive and thermally challenging.

Operating Conditions

This category involves much higher operating pressures, typically ranging from 1 atmosphere to 10 atmospheres. Maintaining a stable, dense plasma under these conditions requires significantly higher microwave power input.

Plasma Approaching Equilibrium

In a high-pressure environment, the frequent collisions between particles cause a much more efficient transfer of energy from the electrons to the neutral gas species. This results in far less temperature imbalance.

This state is described as being near-thermal equilibrium, where the entire plasma volume, including the gas, becomes extremely hot.

The Critical Trade-offs: Pressure vs. Plasma Chemistry

Choosing a pressure regime is not arbitrary; it involves a direct trade-off between process control, deposition rate, and material quality. The core difference lies in the resulting plasma chemistry.

Concentration of Active Species

High-pressure plasma is a much more potent chemical environment. The high temperature and collision rate lead to a significantly higher concentration of atomic hydrogen and other critical radicals. These species are essential for high-quality material growth, particularly for diamond synthesis.

Low-pressure plasma, being cooler and less dense, produces a lower concentration of these active species.

Thermal Management and Complexity

The near-equilibrium state of high-pressure plasma means the gas itself is extremely hot, presenting a major thermal management challenge. Substrates and the reactor itself must be engineered to withstand and dissipate this intense heat.

Low-pressure systems are generally cooler and place less thermal load on the substrate and hardware, simplifying reactor design.

Growth Rate vs. Uniformity

The high density of reactive species in high-pressure plasma often translates to faster deposition rates. However, managing the intense thermal environment to achieve uniform growth over a large area can be more difficult. Low-pressure systems may offer slower growth but potentially better large-area uniformity and process control.

Making the Right Choice for Your Goal

Your application's specific requirements for material quality, growth rate, and substrate sensitivity will determine the ideal MPCVD regime.

- If your primary focus is high-rate, high-quality diamond synthesis: High-pressure MPCVD is the superior choice because it generates the high density of atomic hydrogen required to etch away graphitic carbon and promote sp³ bonding.

- If your primary focus is deposition on temperature-sensitive substrates or fundamental research: Low-pressure MPCVD provides a more controlled, lower-temperature environment that is less likely to damage the substrate and offers a wider process window.

Ultimately, mastering MPCVD requires understanding that pressure and power are not just settings, but levers to control the fundamental chemistry of your plasma.

Summary Table:

| Category | Operating Pressure | Microwave Power | Plasma State | Key Characteristics |

|---|---|---|---|---|

| Low-Pressure Plasma | 10-100 Torr | Lower | Thermal Non-Equilibrium | Cooler, better process control, suitable for sensitive substrates |

| High-Pressure Plasma | 1-10 atm | Higher | Near-Thermal Equilibrium | Hotter, higher growth rates, ideal for high-quality diamond synthesis |

Struggling to choose the right MPCVD plasma regime for your lab's unique needs? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD Systems, with deep customization capabilities to precisely match your experimental requirements. Whether you need high-pressure MPCVD for fast diamond growth or low-pressure systems for delicate substrates, our expert team can help optimize your process. Contact us today to discuss how we can enhance your deposition efficiency and material quality!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- Why is the temperature control system important in MPCVD equipment? Ensure Precise Diamond Growth and Process Stability

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth