At their core, the technical specifications of a box furnace describe a robust, insulated chamber designed for high-temperature batch processing. Standard models feature heavy-duty construction, high-efficiency ceramic fiber insulation, and precise heating controls, typically using either gas burners or electric elements with SCR control. Key components include a machine-mounted NEMA 12 control panel, microprocessor-based temperature controllers, and safety features like a single-button E-stop.

A box furnace is best understood not as a single product, but as a configurable thermal processing platform. While standard features ensure durability and basic operation, the optional specifications for automation, atmosphere control, and temperature uniformity are what truly define its capability for a specific industrial or research application.

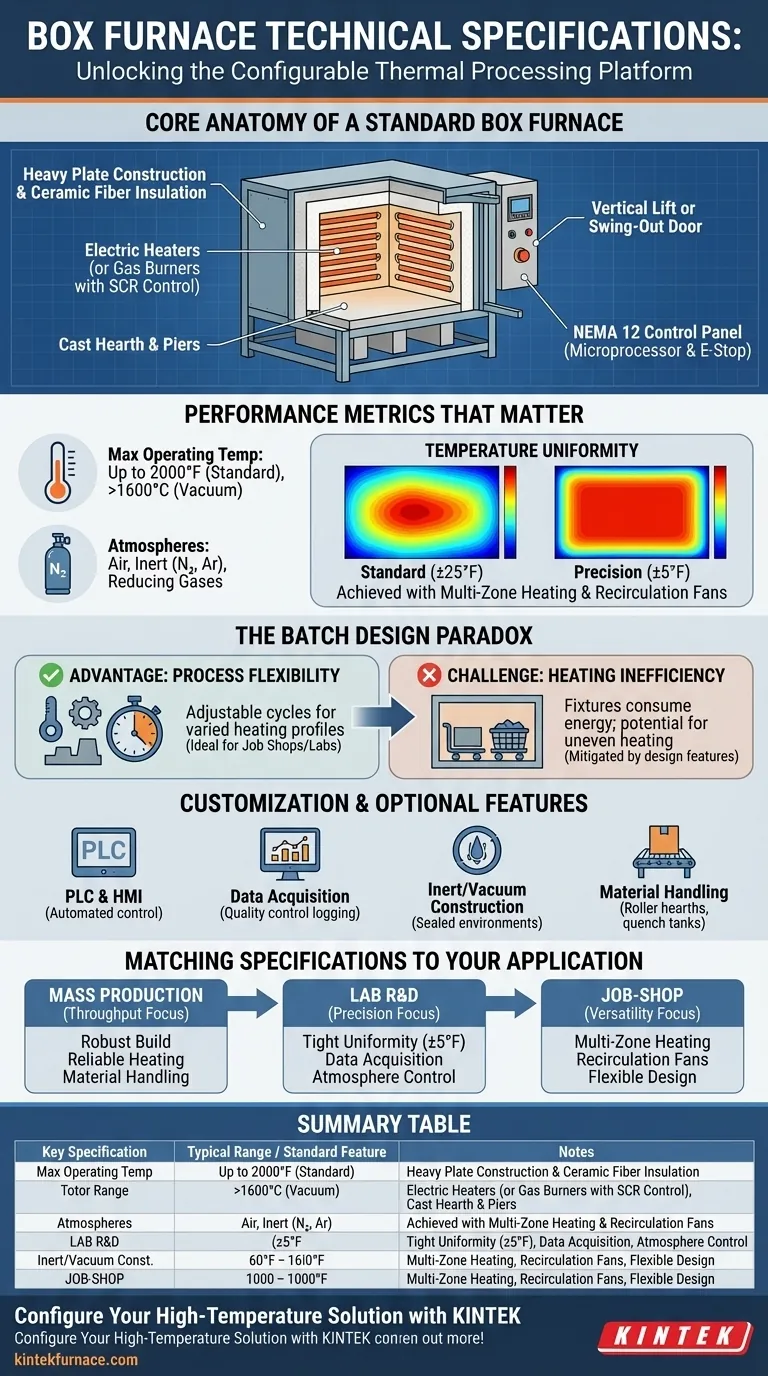

Core Components of a Standard Box Furnace

A standard box furnace is built around a set of proven design features that ensure reliability, safety, and energy efficiency for a wide range of applications.

Structural Integrity and Insulation

A box furnace's foundation is its heavy plate construction, designed to support heavy loads and withstand thermal cycling over many years.

This structure is lined with high-density, energy-efficient ceramic fiber insulation. This material minimizes heat loss, which improves energy consumption and allows the furnace to reach and maintain high temperatures effectively.

Heavy-duty cast hearths and piers are often included to provide a stable, durable surface for placing workpieces directly into the heating chamber.

Heating System and Control

Furnaces are available in both gas and electric versions. Gas models are equipped with burner safety equipment, while electric versions use heaters arranged for maximum coverage.

Heating is managed by fully proportional controls. For electric models, this is typically an SCR (Silicon Controlled Rectifier) control, which provides precise power modulation for stable temperature management.

Control Panel and Safety

Operations are managed from a machine-mounted NEMA 12 control panel, which protects electronics from dust and moisture in an industrial environment.

Standard controls include microprocessor-based temperature controllers for both the main heating chamber and a separate high-limit controller to prevent overheating.

Essential safety features include a single-button E-stop for immediate shutdown and a multi-function electronic timer, often with an end-of-cycle indicator.

Loading and Access

Product loading and unloading are facilitated by either a vertical lift or a swing-out door. An electric vertical lift door is a common standard feature.

Loading is typically performed manually, often using equipment like a forklift or a roller hearth system.

Performance Metrics That Matter

Beyond the physical components, the true value of a furnace is defined by its performance capabilities, particularly its temperature range and uniformity.

Operating Temperature and Atmosphere

Most standard box furnaces are rated for temperatures up to 2000°F (approx. 1093°C). Specialized models, such as vacuum furnaces, can reach much higher temperatures, often exceeding 1600°C.

They can be designed to operate in various atmospheres, including standard air, inert gases (like nitrogen or argon), or reducing gases, depending on the process requirements.

Temperature Uniformity

Temperature uniformity measures how consistent the temperature is throughout the entire heated chamber. This is a critical specification for quality control.

The standard uniformity is typically ±25°F. However, for processes requiring higher precision, such as in laboratory research or aerospace, furnaces can be configured for uniformities as tight as ±5°F.

Achieving tight uniformity often involves optional features like multi-zone heating technology or recirculation fans to ensure even heat distribution.

Understanding the Trade-offs of a Batch Design

Box furnaces are a type of batch furnace, a design that comes with distinct advantages and challenges that you must consider.

The Advantage: Process Flexibility

The primary benefit of a batch furnace is its flexibility. The temperature and cycle duration can be adjusted for each individual batch.

This makes them ideal for job shops or labs that handle parts requiring a wide range of different heating profiles.

The Challenge: Heating Inefficiency

A notable drawback is that anything placed inside the furnace, including fixtures like carts, baskets, or trays, must also be heated. This consumes additional energy with every cycle.

Furthermore, parts located closest to the heat source will heat faster than those in the center of the load. This can result in uneven heating unless the furnace is specifically designed with features to mitigate it.

Customization and Optional Features

Optional features allow you to tailor a box furnace to a highly specific task, moving from a general-purpose tool to a specialized piece of industrial equipment.

Advanced Process Control

For automated and repeatable cycles, furnaces can be equipped with a PLC (Programmable Logic Controller) and HMI (Human-Machine Interface).

Data acquisition systems can be integrated to log process variables for quality control, analysis, and certification. An automatic shutdown circuit is another common option for unattended operation.

Specialized Environments

For processes that are sensitive to oxygen, inert gas construction provides a sealed chamber with the necessary ports and systems to maintain a specific atmosphere.

High-end vacuum chamber furnaces represent a further specialization, built with materials like molybdenum heating elements to achieve very high temperatures and vacuum levels.

Material Handling and Integration

To streamline production, the furnace can be integrated with material handling equipment. Options include hearth roller rails, load tables, and adjacent quench tanks for hardening processes.

Matching Specifications to Your Application

Choosing the right specifications depends entirely on your end goal.

- If your primary focus is mass production with consistent heat treatment (e.g., annealing): Prioritize heavy-duty construction, a reliable heating system (gas or electric), and consider material handling options like a roller hearth to improve throughput.

- If your primary focus is high-precision laboratory or materials research: Emphasize specifications for tight temperature uniformity (±5°F), advanced control with a PLC/HMI, data acquisition capabilities, and options for controlled atmospheres.

- If your primary focus is versatile job-shop work with varied parts: Leverage the inherent flexibility of the batch design, but invest in multi-zone heating or recirculation fans to ensure consistent results across different load sizes and configurations.

Understanding these technical specifications empowers you to configure the precise tool required for your specific thermal processing task.

Summary Table:

| Key Specification | Typical Range / Standard Feature | Notes |

|---|---|---|

| Max Operating Temperature | Up to 2000°F (1093°C) | Specialized models (e.g., vacuum) exceed 1600°C. |

| Temperature Uniformity | ±25°F (Standard); ±5°F (Precision) | Critical for quality; achieved with multi-zone heating/fans. |

| Construction & Insulation | Heavy plate with ceramic fiber | Ensures durability and energy efficiency. |

| Control System | Microprocessor-based with SCR control | Provides precise, stable temperature management. |

| Atmosphere | Air, Inert (N2, Ar), Reducing Gases | Configurable for specific process requirements. |

| Primary Application Fit | Mass Production, Lab Research, Job-Shop Work | Specifications should be matched to the primary use case. |

Configure Your High-Temperature Solution with KINTEK

Understanding technical specifications is the first step. The next is configuring a furnace that perfectly aligns with your unique thermal processing requirements—whether for high-volume production, precision R&D, or versatile job-shop work.

Why Partner with KINTEK? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

We don't just sell standard models; we engineer solutions. Tell us about your application, and we'll help you specify the ideal temperature range, uniformity, atmosphere controls, and material handling integrations.

Ready to specify your ideal box furnace? Contact our engineering team today for a personalized consultation and quote.

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of laboratory high-temperature box furnaces in T6 aluminum treatment? Key to Material Strength

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation