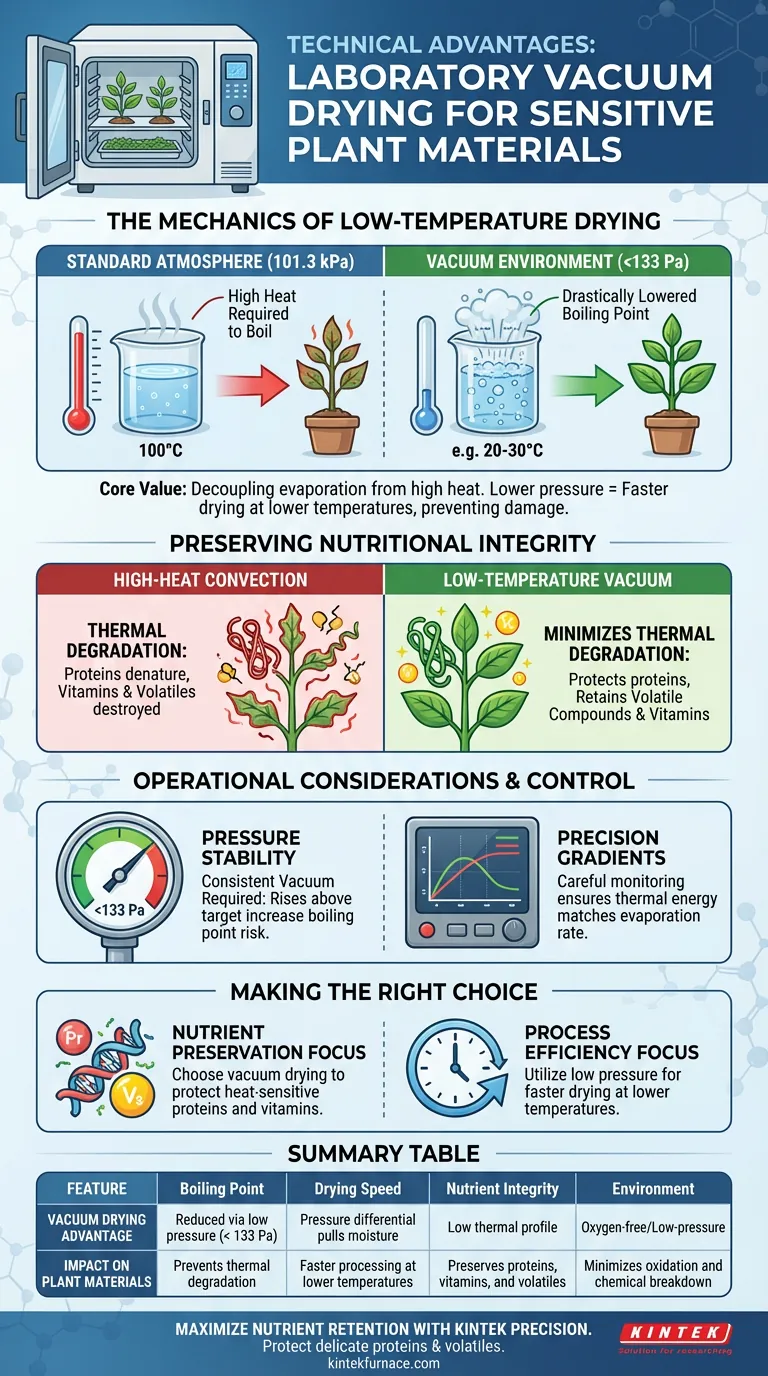

A laboratory vacuum drying oven offers a critical advantage for sensitive plant materials by manipulating the physical properties of water. By creating a controlled low-pressure environment—often below 133 Pa—these units significantly lower the boiling point of the moisture trapped within plant tissues. This allows for rapid drying at much lower temperatures, preventing the heat-induced damage common in standard convection drying.

The core value of this technology lies in decoupling evaporation from high heat. By lowering the atmospheric pressure, you can remove moisture efficiently while keeping the material cool enough to preserve its most fragile chemical structures.

The Mechanics of Low-Temperature Drying

Manipulating the Boiling Point

In a standard environment, water requires significant heat (100°C at sea level) to boil and evaporate. A vacuum oven fundamentally changes this equation.

By reducing the internal pressure to below 133 Pa, the oven drastically drops the temperature required for water to transition from liquid to gas.

Accelerating Process Efficiency

Despite using lower temperatures, the drying process does not necessarily slow down.

The vacuum environment creates a pressure differential that pulls moisture to the surface. This mechanism enables the drying process to proceed faster than ambient drying, even while maintaining a cooler thermal profile.

Preserving Nutritional Integrity

Minimizing Thermal Degradation

The primary danger to plant nutrition during processing is thermal degradation, where heat breaks down complex molecular structures.

Because vacuum drying operates at reduced temperatures, it protects heat-sensitive functional components. This is particularly vital for maintaining the structural integrity of proteins, which can denature and lose efficacy when exposed to high heat.

Retaining Volatile Compounds

Many of the most valuable aspects of plant materials, such as vitamins and volatile phytochemicals, are easily destroyed or evaporated by high temperatures.

A laboratory vacuum oven utilizes precise temperature gradients to remove water without stripping away these lighter, volatile compounds. This maximizes the retention of the plant's original nutritional value and potency.

Operational Considerations

The Requirement for Pressure Stability

To achieve these results, the system relies entirely on maintaining a consistent vacuum.

If the pressure rises above the target range (e.g., exceeding 133 Pa), the boiling point of the water will rise immediately. This introduces a risk of the material overheating if the temperature settings are not adjusted in real-time.

Precision Control Dependencys

Success with this method requires equipment capable of managing precise temperature gradients.

Unlike a simple dehydrator, a vacuum oven requires careful monitoring to ensure the thermal energy applied matches the evaporation rate allowed by the current pressure level.

Making the Right Choice for Your Goal

If your primary focus is Nutrient Preservation: Choose vacuum drying to protect heat-sensitive proteins and vitamins that would otherwise be destroyed by standard heating methods.

If your primary focus is Process Efficiency: Utilize the low-pressure environment to achieve faster drying rates at lower temperatures, reducing the total processing time for delicate batches.

By leveraging the relationship between pressure and temperature, you transform the drying process from a destructive necessity into a preservation step that maintains the full quality of your plant materials.

Summary Table:

| Feature | Vacuum Drying Advantage | Impact on Plant Materials |

|---|---|---|

| Boiling Point | Reduced via low pressure (< 133 Pa) | Prevents thermal degradation of nutrients |

| Drying Speed | Pressure differential pulls moisture | Faster processing at lower temperatures |

| Nutrient Integrity | Low thermal profile | Preserves proteins, vitamins, and volatiles |

| Environment | Oxygen-free/Low-pressure | Minimizes oxidation and chemical breakdown |

Maximize Nutrient Retention with KINTEK Precision

Don't sacrifice your plant material's potency to high-heat processing. KINTEK provides state-of-the-art laboratory vacuum drying systems designed to protect delicate proteins, vitamins, and volatile compounds. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific research or production needs.

Ready to elevate your lab's drying efficiency? Contact us today to discuss your unique requirements and find the perfect high-temp solution.

Visual Guide

References

- Effects of Drying Temperatures on Nutritional and Phytochemical Properties of Gongronema Latifolium Leaves. DOI: 10.63958/azojete/2025/21/2/001

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What design solutions address challenges in vacuum sintering? Optimize Sintering for High-Performance Materials

- What are the technical advantages of using a vacuum environment for drying g-C3N4/Bi2WO6 catalysts?

- What are the advantages of vacuum heat treatment? Achieve Superior Cleanliness and Performance for Critical Parts

- What are the applications of furnace brazing in the medical and pharmaceutical industries? Achieve Sterile, High-Strength Joining

- What are the primary functions of a vacuum furnace? Achieve Superior Material Processing in a Controlled Environment

- How does the controlled environment of a vacuum furnace benefit material processing? Enhance Purity and Performance

- Why does the simulation of magnesium alloy distillation require high precision? Master Vacuum for Purity

- What is the purpose of using a high-vacuum drying oven? Maximize Battery Performance and Electrode Purity