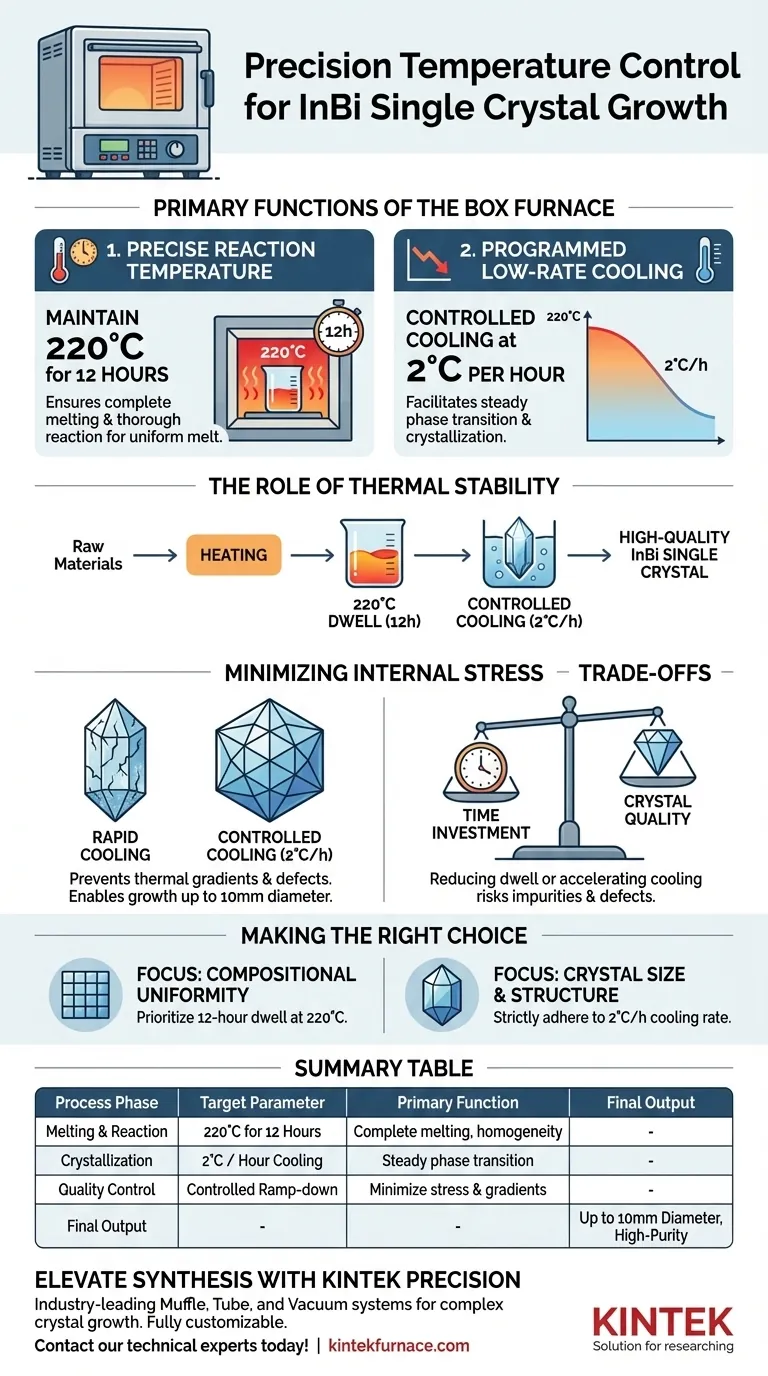

The primary temperature control functions of a box furnace during the growth of InBi single crystals are the maintenance of a precise reaction temperature and the execution of a programmed, low-rate cooling profile. Specifically, the furnace must hold a stable temperature of 220°C for 12 hours to ensure complete melting, followed by a controlled cooling rate of 2°C per hour to facilitate crystallization.

The box furnace serves as a precision tool for managing phase transitions, utilizing extended hold times for material homogeneity and slow cooling rates to minimize internal stress in the final crystal lattice.

The Role of Thermal Stability in Crystal Synthesis

A box furnace is not merely a heating element; it is an environment controller. For InBi growth, the furnace manages a specific thermal profile that dictates the internal structure and size of the resulting crystal.

Ensuring Complete Melting and Reaction

The first critical function is achieving a stable high-temperature dwell.

The furnace heats the raw materials to 220°C.

It maintains this temperature for a duration of 12 hours.

This extended hold time is essential to ensure that the raw materials melt completely and react thoroughly, creating a uniform melt prior to crystallization.

Precise Programmed Cooling

Once the melt is homogenized, the furnace shifts to its most critical function: controlled cooling.

The furnace ramps down the temperature at a specific, slow rate of 2°C per hour.

This slow rate is necessary to maintain thermodynamic equilibrium as the material transitions from liquid to solid.

Minimizing Internal Stress

The specific cooling rate of 2°C/h is not arbitrary; it is a mechanism for quality control.

Rapid cooling would introduce thermal gradients, leading to defects or internal stress within the crystal.

By controlling the rate precisely, the furnace allows the crystal lattice to form without significant strain.

This stability enables the growth of high-quality single crystals with large diameters, specifically achieving sizes up to 10 mm.

Understanding the Trade-offs

While the box furnace enables high-quality growth, the process requires a significant investment in time to achieve material stability.

Time vs. Quality

The primary trade-off in this thermal profile is the duration of the process versus the structural integrity of the crystal.

Reducing the 12-hour dwell time risks incomplete reaction of the raw materials, leading to impurities in the final crystal.

Accelerating the 2°C/h cooling rate to save time will almost invariably increase internal stress, reducing the crystal's size and introducing defects.

Making the Right Choice for Your Goal

To optimize the growth of InBi crystals, you must prioritize specific thermal parameters based on your outcome requirements.

- If your primary focus is Compositional Uniformity: Ensure the furnace is programmed for the full 12-hour dwell at 220°C to guarantee a complete reaction of the melt.

- If your primary focus is Crystal Size and Structural Quality: Strictly adhere to the 2°C/h cooling rate to minimize stress and maximize the diameter of the single crystal.

Precision in thermal profiling is the defining factor that transforms raw InBi materials into high-quality, large-diameter single crystals.

Summary Table:

| Process Phase | Target Parameter | Primary Function |

|---|---|---|

| Melting & Reaction | 220°C for 12 Hours | Ensures complete melting and chemical homogeneity |

| Crystallization | 2°C / Hour Cooling | Facilitates steady phase transition and lattice formation |

| Quality Control | Controlled Ramp-down | Minimizes internal stress and thermal gradients |

| Final Output | Up to 10mm Diameter | Produces large-scale, high-purity single crystals |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect 2°C/h cooling profile for InBi crystals requires equipment that offers uncompromising thermal stability. KINTEK provides industry-leading Muffle, Tube, and Vacuum systems specifically engineered for complex crystal growth and high-temp laboratory research. Backed by expert R&D and manufacturing, our furnaces are fully customizable to meet your unique dwell and ramp-rate requirements.

Ready to optimize your crystal quality? Contact our technical experts today to find the perfect furnace for your laboratory needs!

Visual Guide

References

- Thomas J. Rehaag, Gavin R. Bell. Cleaved surfaces and homoepitaxial growth of InBi(001). DOI: 10.1088/2053-1591/adfc2d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does the feeding and discharging device contribute to the operation of a box furnace? Enhance Safety and Process Control

- What is the proper procedure after completing an experiment with the muffle furnace? Ensure Safety and Accuracy in Your Lab

- What is the reputation of box furnaces in terms of quality and reliability? Trusted for Decades in High-Stakes Applications

- What is the function of a laboratory furnace in fire-resistant material testing? Ensure Precise EN 1363-1 Compliance

- What are the construction features and temperature capabilities of a muffle furnace? Key Insights for Your Lab

- What is the technical role of a muffle furnace in dyeing sludge ash preparation? Optimize Pozzolanic Activation

- What are the limitations of muffle furnaces in industrial applications? Uncover Key Constraints for Smart Lab Choices

- What is the function of a muffle furnace in ZnNPs synthesis? Achieve Pure, Crystalline Zinc Oxide