In essence, a high-quality dental lab furnace is defined by its durable construction, precise temperature control, and its ability to create a controlled atmosphere for material purity. These characteristics ensure it can consistently produce accurate dental restorations like crowns, bridges, and implants from a variety of materials, including alloys, ceramics, and precious metals.

The core function of a dental lab furnace isn't just to get hot; it's to achieve and maintain exact temperatures under specific atmospheric conditions. This precision is the defining characteristic of quality, directly impacting the integrity and fit of the final dental prosthesis.

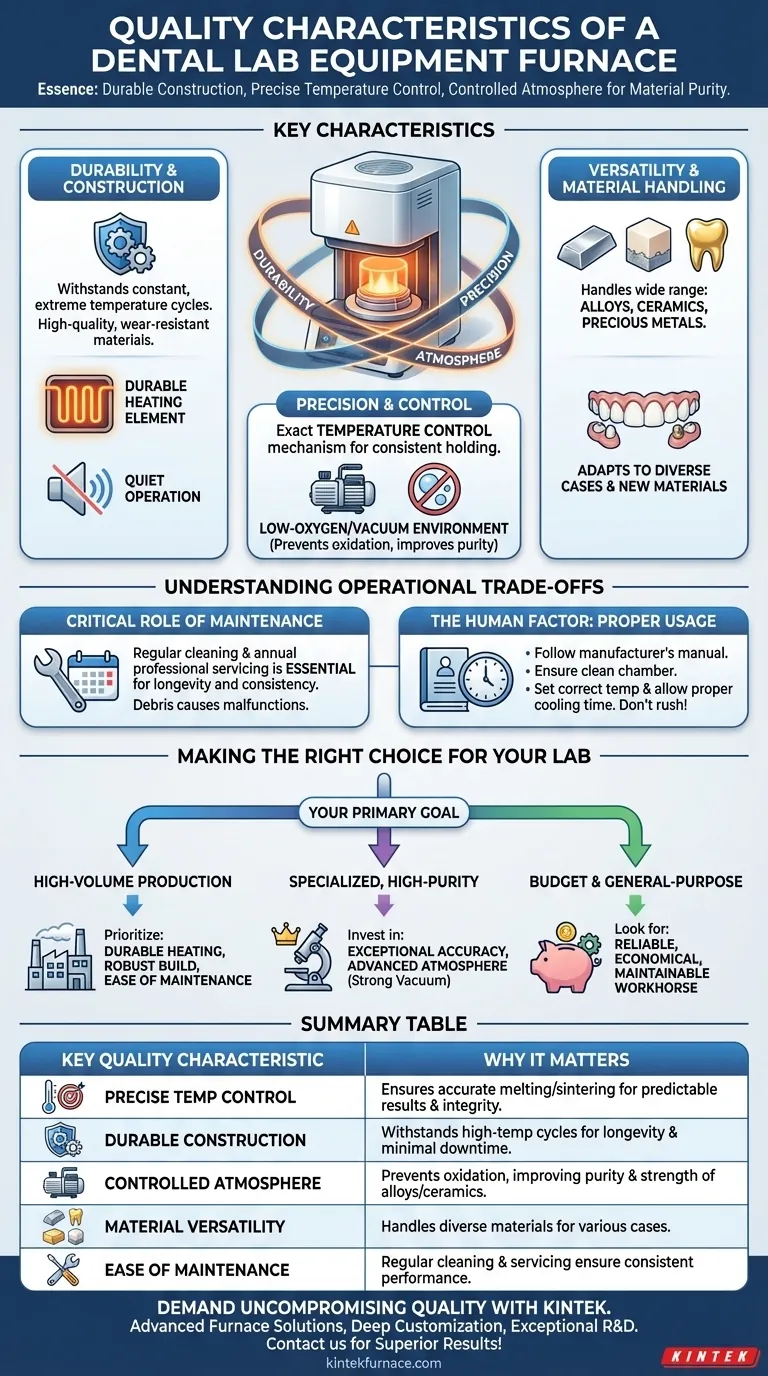

Key Characteristics of a Quality Furnace

A reliable dental furnace is a cornerstone of any dental laboratory. Its performance directly translates to the quality of the final product. The key indicators of quality go beyond simple heating capabilities.

Durability and Construction

The furnace must be built to withstand constant, extreme temperature cycles. High-quality materials resistant to wear and tear are non-negotiable for longevity and safety.

The heating element is the heart of the furnace. It must be made from a durable, long-lasting material capable of withstanding very high temperatures without degrading quickly.

Finally, a well-designed furnace operates quietly. While not directly related to casting quality, this contributes significantly to a more comfortable and productive working environment for technicians.

Precision and Control

This is arguably the most critical characteristic. A superior furnace offers an exact temperature control mechanism. This ensures the furnace reaches the specific melting or sintering point required and holds it consistently, which is vital for predictable results.

The ability to operate in low-oxygen environments, often by creating a vacuum, is another hallmark of a quality unit. This prevents oxidation and improves the purity and strength of the final casted materials, especially sensitive alloys.

Versatility and Material Handling

A valuable furnace is not a one-trick pony. It should be capable of melting and casting a wide range of dental materials, from various alloys and ceramics to precious metals.

This versatility allows a lab to handle diverse cases and adapt to new materials as they become available, making the furnace a better long-term investment.

Understanding the Operational Trade-offs

While modern furnaces are designed for efficiency, their performance is directly tied to their operation and maintenance. Ignoring these factors can undermine the quality of even the best equipment.

The Critical Role of Maintenance

Regular maintenance is not optional; it is essential for optimal functioning and longevity. The references strongly recommend professional servicing at least once a year.

Between professional check-ups, regularly cleaning the furnace chamber and its components is crucial. Debris can contaminate casts and interfere with heating, leading to malfunctions and inconsistent results.

The Human Factor: Proper Usage

A furnace is only as good as its operator. Before use, one must always ensure the furnace is clean and free of any residual debris from previous cycles.

Following the manufacturer's user manual is paramount. This includes setting the correct temperature for the specific material being used and allowing for proper cooling time before removing the final product. Rushing these steps can compromise the restoration's integrity.

Making the Right Choice for Your Lab

Selecting a furnace requires balancing precision, durability, and cost. Your primary goal will dictate which characteristics matter most.

- If your primary focus is high-volume production: Prioritize furnaces known for their durable heating elements, robust construction, and ease of maintenance to minimize downtime.

- If your primary focus is specialized, high-purity restorations (e.g., advanced ceramics or alloys): Invest in a furnace with exceptional temperature accuracy and advanced atmospheric controls, such as a strong vacuum pump.

- If your primary focus is budget and general-purpose use: Look for a reliable, easy-to-use model from a reputable brand that, while perhaps less specialized, is known for being an economical and maintainable workhorse.

Ultimately, a quality dental furnace is an investment in consistency, accuracy, and the long-term success of your laboratory's output.

Summary Table:

| Key Quality Characteristic | Why It Matters |

|---|---|

| Precise Temperature Control | Ensures accurate melting/sintering points for predictable results and material integrity. |

| Durable Construction & Heating Element | Withstands constant high-temperature cycles for longevity and minimal downtime. |

| Controlled Atmosphere (e.g., Vacuum) | Prevents oxidation, improving the purity and strength of alloys and ceramics. |

| Material Versatility | Handles a wide range of materials (alloys, ceramics, precious metals) for diverse cases. |

| Ease of Maintenance | Regular cleaning and professional servicing ensure consistent performance and results. |

Demand Uncompromising Quality for Your Dental Lab

Your reputation is built on the precision and consistency of every crown, bridge, and implant. KINTEK understands this. Leveraging our exceptional R&D and in-house manufacturing, we provide dental laboratories with advanced furnace solutions engineered for excellence.

Our product line, including high-precision Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities to meet your lab's unique workflow and material requirements. Whether you focus on high-volume production or specialized, high-purity restorations, we have a solution to enhance your output's quality and reliability.

Ready to invest in a furnace that guarantees superior results? Contact KINTEK today to discuss your specific needs and discover how our expertise can become your competitive advantage.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique