For heating element applications, nickel-chromium (Ni-Cr) alloys are a dominant choice due to their unique combination of high electrical resistance and exceptional high-temperature durability. When an electric current passes through them, this resistance generates significant heat. Simultaneously, the alloy forms a protective surface layer that prevents it from degrading, enabling a long operational life.

The selection of a heating element material is rarely about finding the highest temperature resistance alone. It is a critical trade-off between performance, operational lifespan, and cost, where nickel-chromium alloys provide the optimal balance for the vast majority of industrial and commercial applications.

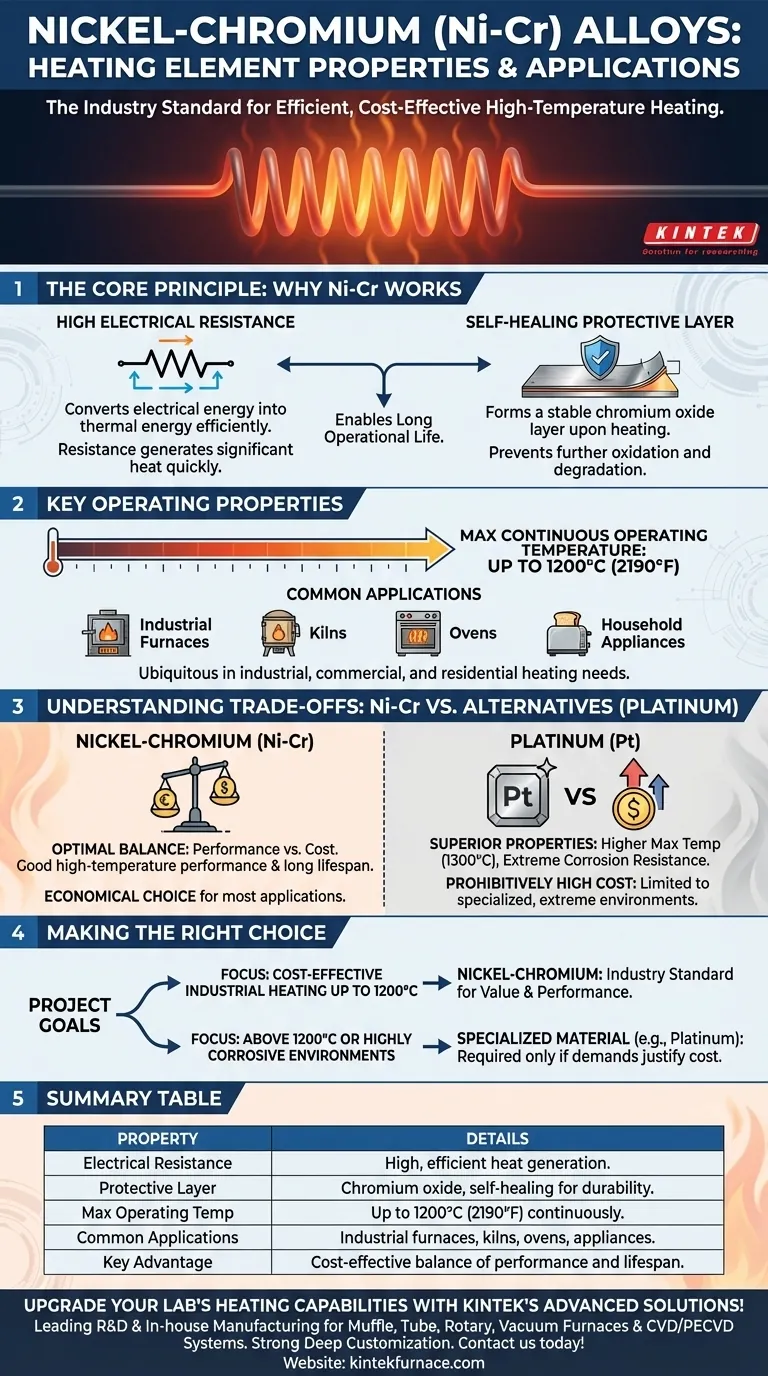

The Core Principle: Why Ni-Cr Works

The effectiveness of nickel-chromium alloys as heating elements is rooted in two fundamental material properties that work in tandem.

High Electrical Resistance

Heating elements function by converting electrical energy into thermal energy. The high electrical resistance of Ni-Cr alloys is the key to this process, allowing them to generate heat efficiently and quickly when a current is applied.

The Self-Healing Protective Layer

When first heated in the presence of air, the chromium within the alloy oxidizes. This creates a thin, adherent, and stable layer of chromium oxide on the surface of the element.

This passivating layer is the alloy's most critical feature. It acts as a barrier, preventing atmospheric oxygen from reaching the underlying metal and causing further oxidation or degradation, which would lead to premature failure.

Key Operating Properties

Understanding the practical limits and common uses of Ni-Cr is essential for proper application design.

Maximum Operating Temperature

While the alloy can physically withstand brief temperatures up to 1600°C, its practical continuous operating limit is determined by the stability of the protective oxide layer.

For continuous, reliable operation in most industrial settings, nickel-chromium elements are typically used for temperatures up to 1200°C (2190°F).

Common Applications

The excellent cost-to-performance ratio of Ni-Cr makes it ubiquitous. You will find it in a vast range of applications, from common household appliances to heavy industrial equipment.

Its primary use is in industrial furnaces, kilns, ovens, and any process requiring consistent and reliable electric heat.

Understanding the Trade-offs: Ni-Cr vs. Alternatives

No material is perfect for every scenario. Comparing nickel-chromium to a more specialized material like platinum reveals the critical balance of factors at play.

Performance vs. Cost: The Platinum Example

Platinum (Pt) is a superior material in several respects. It has a higher continuous operating temperature (up to 1300°C), a higher melting point (1768°C), and outstanding resistance to corrosion.

However, these enhanced properties come at a prohibitively high cost. This financial reality limits its use to highly specialized laboratory equipment or applications where extreme chemical inertness is non-negotiable.

The Economic Justification for Ni-Cr

Nickel-chromium offers performance that is "good enough" for the vast majority of heating needs, but at a fraction of the cost of alternatives like platinum.

It strikes the ideal economic balance, providing excellent high-temperature performance and a long service life without the extreme expense of precious metals. This makes it the default, most logical choice for most designs.

Making the Right Choice for Your Application

Your material selection should be driven by the specific goals and constraints of your project.

- If your primary focus is cost-effective industrial heating up to 1200°C: Nickel-chromium is the industry standard, offering the best combination of performance, durability, and value.

- If your primary focus is operating above 1200°C or in a highly corrosive environment: A more specialized and expensive material like platinum may be required, but only if the application's demands justify the significant cost.

Understanding these core material properties empowers you to select the most reliable and economical solution for your specific heating requirements.

Summary Table:

| Property/Application | Details |

|---|---|

| Electrical Resistance | High, enabling efficient heat generation |

| Protective Layer | Chromium oxide, self-healing for durability |

| Max Operating Temp | Up to 1200°C (2190°F) continuously |

| Common Applications | Industrial furnaces, kilns, ovens, appliances |

| Key Advantage | Cost-effective balance of performance and lifespan |

Upgrade your lab's heating capabilities with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how our tailored heating elements can benefit your specific applications!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability