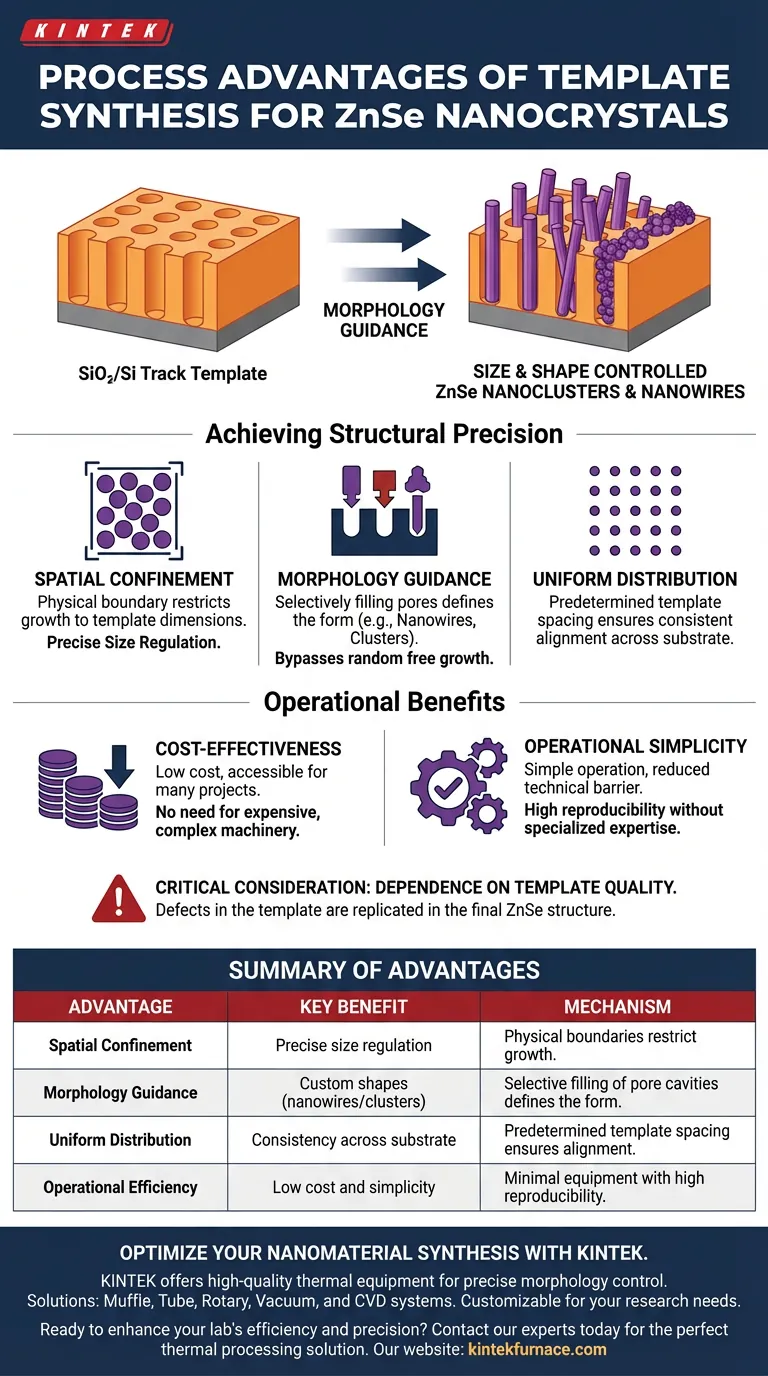

Template synthesis provides a distinct advantage in the fabrication of zinc selenide (ZnSe) nanocrystals by utilizing a physical mold to dictate the final structure of the material. The primary benefits of this process are the precise regulation of crystal size through spatial confinement, the ability to achieve uniform distribution, and significant operational efficiencies characterized by low cost and simplicity.

Core Takeaway: The defining strength of template synthesis is morphology guidance. By selectively filling pre-existing pore cavities, you can bypass the randomness of free growth to produce size-controlled semiconductor nanoclusters and nanowires ideal for optoelectronic research.

Achieving Structural Precision

Mastering Spatial Confinement

The fundamental advantage of this method is spatial confinement.

Rather than allowing crystals to grow unrestricted, the process uses pre-prepared silica/silicon (SiO2/Si) track templates.

These templates act as a physical boundary, restricting the growth of the ZnSe to the exact dimensions of the available space.

Morphology Guidance

This technique allows you to intentionally shape the nanomaterial.

By selectively filling the pore cavities of the template, you can determine the specific form the ZnSe takes.

This is particularly effective for creating specific structures like nanoclusters and nanowires that are difficult to achieve through uncontrolled chemical precipitation.

Uniform Distribution

Consistency is often a major challenge in nanomaterial fabrication.

Template synthesis ensures that the resulting ZnSe structures are uniformly distributed across the substrate.

Because the template itself is fixed, the spacing and arrangement of the nanocrystals are predetermined and consistent.

Operational Benefits

Cost-Effectiveness

For many research applications, budget constraints drive process selection.

This method is characterized by low cost, making it accessible for a wide range of projects.

It avoids the need for the expensive, high-maintenance machinery often required for advanced lithography or epitaxial growth.

Operational Simplicity

Complexity often introduces variables that lead to errors.

Template synthesis offers simple operation, reducing the technical barrier to entry.

This simplicity allows for high reproducibility without requiring highly specialized operational expertise.

Critical Considerations

Dependence on Template Quality

While the process is advantageous, it is not independent.

The quality of your ZnSe nanocrystals is directly tied to the quality of your SiO2/Si track templates.

Any defect or irregularity in the pre-prepared template will be faithfully replicated in the final semiconductor structure.

Making the Right Choice for Your Goal

Template synthesis is a powerful tool when structural definition and budget are your primary constraints.

- If your primary focus is Structural Precision: Leverage the spatial confinement capabilities to enforce exact size and shape control for nanowires or nanoclusters.

- If your primary focus is Project Efficiency: Utilize this method for its low cost and simple operation to establish a high-quality structural foundation without excessive overhead.

This approach offers a practical balance between high-quality structural control and operational feasibility.

Summary Table:

| Advantage | Key Benefit | Mechanism |

|---|---|---|

| Spatial Confinement | Precise size regulation | Physical boundaries of the mold restrict growth. |

| Morphology Guidance | Custom shapes (nanowires/clusters) | Selective filling of pore cavities defines the form. |

| Uniform Distribution | Consistency across substrate | Predetermined template spacing ensures alignment. |

| Operational Efficiency | Low cost and simplicity | Minimal equipment requirements with high reproducibility. |

Optimize Your Nanomaterial Synthesis with KINTEK

Precise morphology control in ZnSe nanocrystals requires a foundation of high-quality thermal equipment. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique research needs. Whether you are focusing on spatial confinement or scaling up production, our high-temp furnaces provide the stability your templates demand.

Ready to enhance your lab's efficiency and structural precision? Contact our experts today to find the perfect thermal processing solution for your project.

Visual Guide

References

- Aiman Akylbekovа, А. Usseinov. RAMAN ANALYSIS OF NANOCRYSTALS BASED ON ZINC SELENIDE. DOI: 10.52676/1729-7885-2023-4-77-84

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Spark Plasma Sintering SPS Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the role of a water-cooled solid end? Master Thermal Gradients in Directional Solidification

- What are the advantages of using a vacuum drying oven for precursors on carbon paper? Maximize Material Performance

- What role does a PID controller play in the calcination process of eggshells? Precision Control for Pure Calcium Oxide

- How does high-temperature filtration equipment facilitate molten salt separation? Boost Your Slag Treatment Recovery

- How does high-temperature calcination affect kaolin? Boost Surface Area and Catalytic Reactivity via Thermal Processing

- What is the significance of rapid quenching equipment in verifying the reaction pathway of BiFeO3? Capturing Intermediate Phases

- What is the purpose of bottom-entry argon injection? Enhance Lithium-ion Battery Safety & Purge Efficiency

- What is the significance of using high-temperature heating equipment to reach 1250°C for alloys? Stress Test Excellence