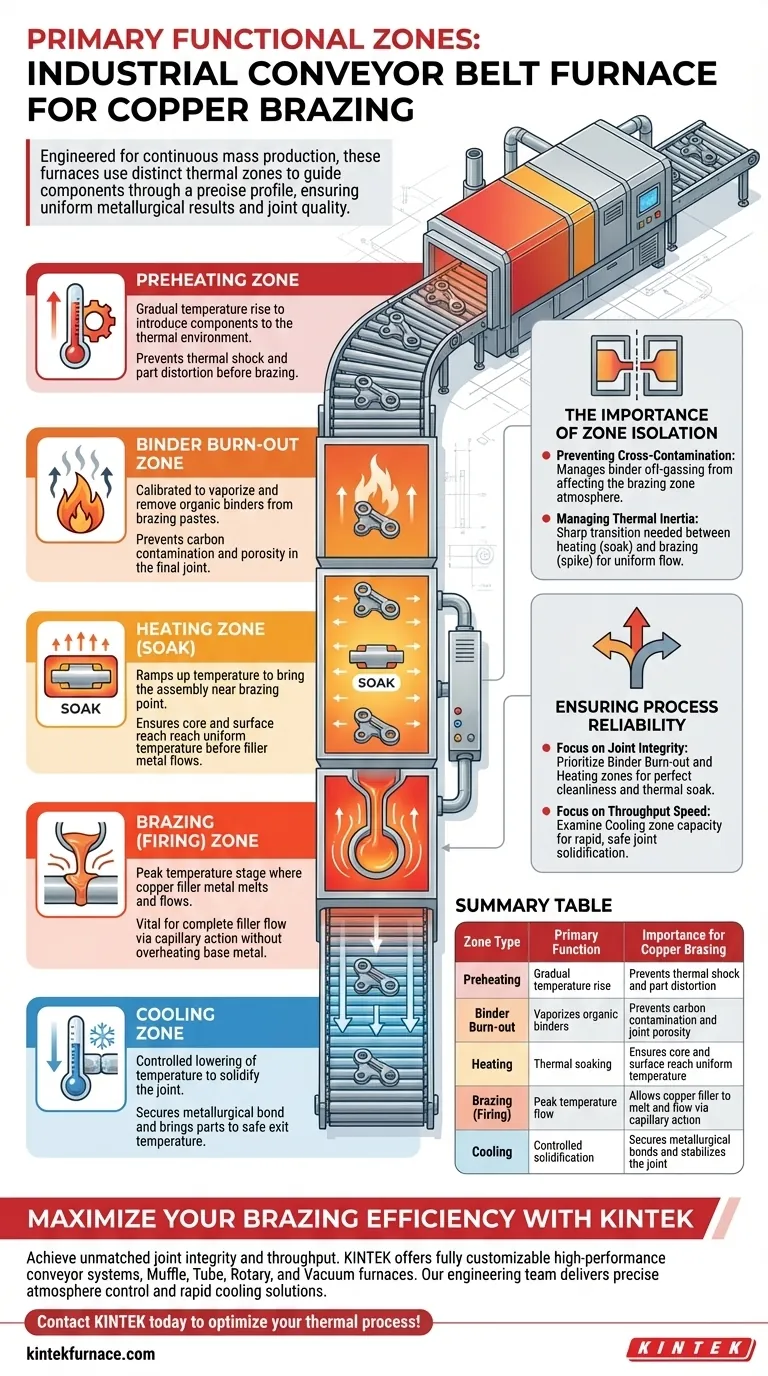

An industrial conveyor belt furnace for copper brazing operates using five primary functional zones: the preheating zone, the binder burn-out zone, the heating zone, the brazing (firing) zone, and the cooling zone. These distinct sections are engineered to guide components through a precise thermal profile, ensuring continuous processing and consistent metallurgical results.

By compartmentalizing the thermal cycle into specialized zones, these furnaces ensure that every component experiences identical heating, soaking, and cooling conditions, resulting in uniform joint quality across high-volume production batches.

The Anatomy of the Thermal Process

To achieve mass-production quality, the furnace must control the environment far beyond simple heating. Each zone plays a critical role in preparing, joining, and stabilizing the metal components.

The Preheating Zone

This initial stage introduces the components to the thermal environment.

Its primary function is to raise the temperature of the assembly gradually. This prevents thermal shock, which can distort parts or dislodge fixtures before the actual brazing process begins.

The Binder Burn-out Zone

In many mass-production scenarios, brazing pastes are used, which contain organic binders to hold the filler metal in place.

This zone is specifically calibrated to vaporize and remove these binders. Removing these organics prior to higher temperatures is essential to prevent carbon contamination and porosity in the final brazed joint.

The Heating Zone

Once the binders are removed, the components enter the main heating zone.

Here, the temperature is ramped up significantly to bring the assembly near the brazing temperature. This zone ensures the "soak"—meaning the core of the part reaches the same temperature as the surface—is achieved before the filler metal flows.

The Brazing (Firing) Zone

This is the critical process zone where the peak temperature is reached.

In this section, the copper filler metal melts and flows into the joint via capillary action. Precise thermal distribution here is vital to ensure the filler flows completely without overheating or damaging the base metal.

The Cooling Zone

After the brazing reaction is complete, the components move immediately into the cooling zone.

This section lowers the temperature in a controlled manner to solidify the joint. Controlled cooling is necessary to secure the metallurgical bond and bring the parts to a safe temperature for exiting the furnace.

The Importance of Zone Isolation

While the conveyor moves continuously, the success of the process depends on the distinct separation of these thermal environments.

Preventing Cross-Contamination

The binder burn-out zone must be effectively managed to ensure off-gassing does not affect the atmosphere in the brazing zone. If organic vapors drift into the firing zone, they can interfere with the wetting action of the copper.

Managing Thermal Inertia

The transition between the heating zone (soak) and the brazing zone (spike) must be sharp enough to trigger flow but stable enough to maintain uniformity. If the zones are not distinct, the thermal profile becomes "muddy," leading to inconsistent joint strength across the belt width.

Ensuring Process Reliability

When evaluating or operating a conveyor belt furnace, your focus should shift based on your specific production requirements.

If your primary focus is Joint Integrity:

- Prioritize the calibration of the binder burn-out and heating zones to ensure parts are perfectly clean and thermally soaked before the copper melts.

If your primary focus is Throughput Speed:

- Examine the capacity of the cooling zone, as the ability to rapidly and safely solidify the joint often dictates the maximum belt speed.

Successful mass production relies on the seamless interplay of these five zones to deliver a repeatable, high-quality product.

Summary Table:

| Zone Type | Primary Function | Importance for Copper Brazing |

|---|---|---|

| Preheating | Gradual temperature rise | Prevents thermal shock and part distortion |

| Binder Burn-out | Vaporizes organic binders | Prevents carbon contamination and joint porosity |

| Heating | Thermal soaking | Ensures core and surface reach uniform temperature |

| Brazing (Firing) | Peak temperature flow | Allows copper filler to melt and flow via capillary action |

| Cooling | Controlled solidification | Secures metallurgical bonds and stabilizes the joint |

Maximize Your Brazing Efficiency with KINTEK

Achieve unmatched joint integrity and throughput in your mass-production lines. Backed by expert R&D and manufacturing, KINTEK offers high-performance conveyor systems, Muffle, Tube, Rotary, and Vacuum furnaces, all fully customizable to your specific metallurgical needs. Whether you require precise atmosphere control for binder burn-out or rapid cooling for high-speed output, our engineering team is ready to deliver.

Contact KINTEK today to optimize your thermal process!

Visual Guide

References

- Er. RoshanY. Gonnade. Copper Brazing Technology. DOI: 10.22214/ijraset.2025.73740

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a laboratory blast drying oven play in the preparation of Ti-doped Mn3O4? Optimize Your Precursor Quality

- Why is graphite furnace AAS more sensitive than flame AAS? Unlocking Trace-Level Detection

- How do h-BN targets improve memristor switching ratios? Maximize Logic Windows with High-Purity Precursors

- Why is a two-stage sintering process used for porous LATP? Master Structural Integrity and Porosity

- What are the advantages of using a vacuum oven for drying porous carbon? Protect Microstructures & Prevent Oxidation

- How does the buried-sintering method affect BCZT ceramics performance? Optimize Your Sintering for Peak Piezoelectricity

- Why is an electric blast drying oven required for CRP microstructure analysis? Ensure Data Accuracy with Proper Drying

- Why is a constant temperature and humidity curing chamber essential for geopolymerization? Ensure Structural Strength