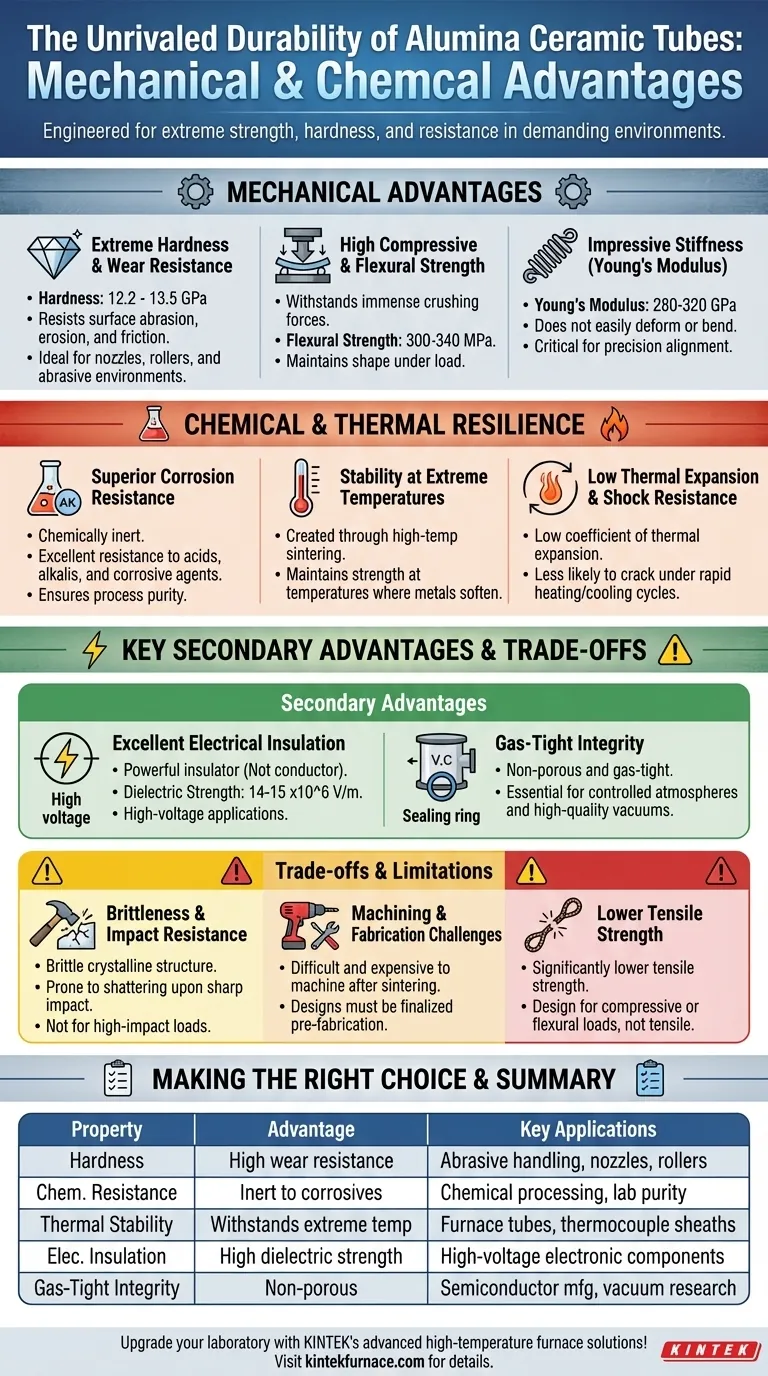

Fundamentally, alumina ceramic tubes offer exceptional durability in environments where most other materials would quickly fail. They are a highly engineered solution prized for their immense strength and hardness, combined with extreme resistance to chemical corrosion and high temperatures. This unique combination makes them a critical component in demanding industrial, chemical, and high-tech applications.

The true advantage of alumina ceramic is not any single property, but its rare combination of extreme hardness, thermal stability, and chemical inertness. This allows it to maintain its structural integrity and ensure process purity in high-temperature, high-wear, and corrosive conditions where metals and plastics cannot perform.

Deconstructing the Mechanical Advantages

The mechanical properties of alumina are what define its ability to withstand physical stress. These are not just abstract numbers; they translate directly to reliability and longevity in the field.

Extreme Hardness and Wear Resistance

Alumina is an exceptionally hard material, with a hardness rating of 12.2 to 13.5 GPa. This makes it highly resistant to surface abrasion, erosion, and friction.

In practice, this means it excels in applications involving contact with abrasive particles or constant movement, such as protection tubes, nozzles, or rollers, without wearing down.

High Compressive and Flexural Strength

Alumina tubes exhibit very high compressive strength, meaning they can withstand immense crushing forces without fracturing.

They also possess good flexural strength (300-340 MPa), which is the ability to resist bending or snapping under a load. This ensures the tube maintains its shape and integrity under significant mechanical stress.

Impressive Stiffness (Young's Modulus)

With a Young's Modulus between 280-320 GPa, alumina is incredibly stiff. This means the material does not easily deform, bend, or flex when a force is applied.

This high stiffness is critical for precision applications where maintaining exact dimensions and alignment under load is non-negotiable.

Understanding the Chemical and Thermal Resilience

Beyond physical strength, alumina's ability to resist chemical and thermal breakdown is often its most important feature.

Superior Corrosion Resistance

High-purity alumina is chemically inert. It shows excellent resistance to attack from a wide range of acids, alkalis, and other corrosive agents, even at elevated temperatures.

This property is vital for chemical processing and laboratory work, where it ensures the purity of the process by not leaching contaminants into the system.

Stability at Extreme Temperatures

Created through a high-temperature sintering process, alumina tubes are built to withstand a thermal environment. They maintain their strength and structure at temperatures where metals would soften or melt.

This makes them the ideal choice for furnace tubes, thermocouple sheaths, and other components used in metallurgy and high-temperature manufacturing.

Low Thermal Expansion and Shock Resistance

Alumina has a low coefficient of thermal expansion, meaning it does not expand or contract सेवाsignificantly with temperature changes.

This stability, combined with its good thermal conductivity, gives it strong resistance to thermal shock. It is less likely to crack or fail when subjected to rapid heating or cooling cycles.

Key Secondary Advantages

Beyond its core mechanical and chemical strengths, alumina offers other properties that make it a uniquely versatile material.

Excellent Electrical Insulation

Contrary to some misconceptions, alumina is a powerful electrical insulator, not a conductor. It has a high dielectric strength (14-15 x10^6 V/m), preventing the flow of electricity.

This property, दिसंबरd with its thermal stability, makes it perfect for insulators and components in high-voltage and high-temperature electronic applications.

Gas-Tight Integrity

Alumina ceramic tubes can be manufactured to be non-porous and gas-tight. This impermeability is essential for creating a controlled atmosphere or a high-quality vacuum.

This is a critical requirement in semiconductor manufacturing, advanced material research, and any process that demands a pure, protected environment at high temperatures.

Understanding the Trade-offs

No material is perfect. Acknowledging alumina's limitations is key to using it成功fully. Its greatest strengths are directly linked to its primary weaknesses.

Brittleness and Impact Resistance

The same crystalline structure that makes alumina incredibly hard also makes it brittle. Unlike a metal, which will dent or deform upon sharp impact, an alumina tube is more likely to shatter.

It is not suitable for applications involving high-impact loads or a risk of being dropped or struck.

Machining and Fabrication Challenges

Alumina's extreme hardness makes it very difficult and expensive to machine or modify after it has been sintered.

Designs must be finalized before fabrication, as post-production adjustments are impractical. This can limit design flexibility and increase the cost of custom components.

Lower Tensile Strength

While its compressive strength is phenomenal, alumina's tensile strength—its ability to resist being pulled apart—is significantly lower. This is a classic characteristic of ceramic materials.

Care must be taken in a design to ensure loads are primarily compressive or flexural, not tensile.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary goal.

- If your primary focus is maximum durability and wear resistance: Alumina's hardness and compressive strength make it идеаль for rollers, bearings, and nozzles that handle abrasive materials.

- If your primary focus is high-temperature chemical purity: Its corrosion resistance, thermal stability, and gas-tight nature are perfect for furnace tubes and chemical processing reactors.

- If your primary focus is high-voltage electrical insulation: Its high dielectric strength and ability to withstand heat make it the superior choice for insulators in harsh environments.

- If your primary focus is structural stiffness: Alumina's high Young's Modulus is excellent, but you must design around its inherent brittleness and avoid impact loads.

Choose alumina when your objective is to defeat a combination of heat, corrosion, and wear in a single, robust solution.

Summary Table:

| Property | Advantage | Key Applications |

|---|---|---|

| Mechanical Hardness | High wear resistance (12.2-13.5 GPa) | Abrasive particle handling, nozzles, rollers |

| Chemical Resistance | Inert to acids, alkalis, and corrosive agents | Chemical processing, laboratory purity maintenance |

| Thermal Stability | Withstands extreme temperatures without degradation | Furnace tubes, thermocouple sheaths, high-temp manufacturing |

| Electrical Insulation | High dielectric strength (14-15 x10^6 V/m) | High-voltage and high-temperature electronic components |

| Gas-Tight Integrity | Non-porous for controlled atmospheres and vacuums | Semiconductor manufacturing, advanced material research |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable alumina ceramic tubes and custom furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing durability and performance in high-wear, corrosive, and high-temperature environments. Contact us today to discuss how we can optimize your processes and deliver tailored solutions for your specific challenges!

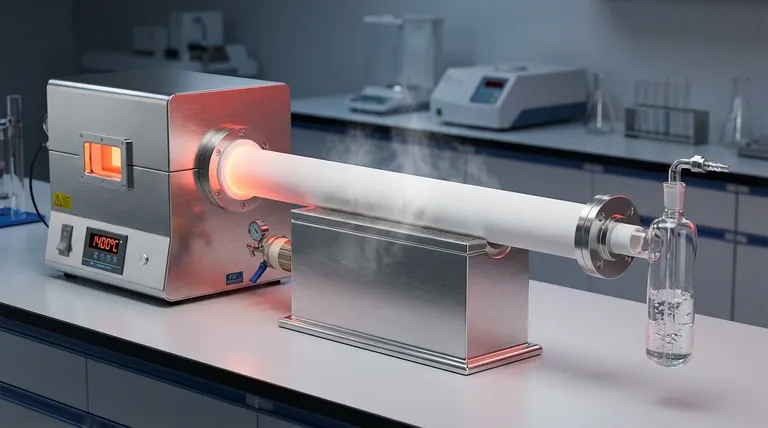

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment