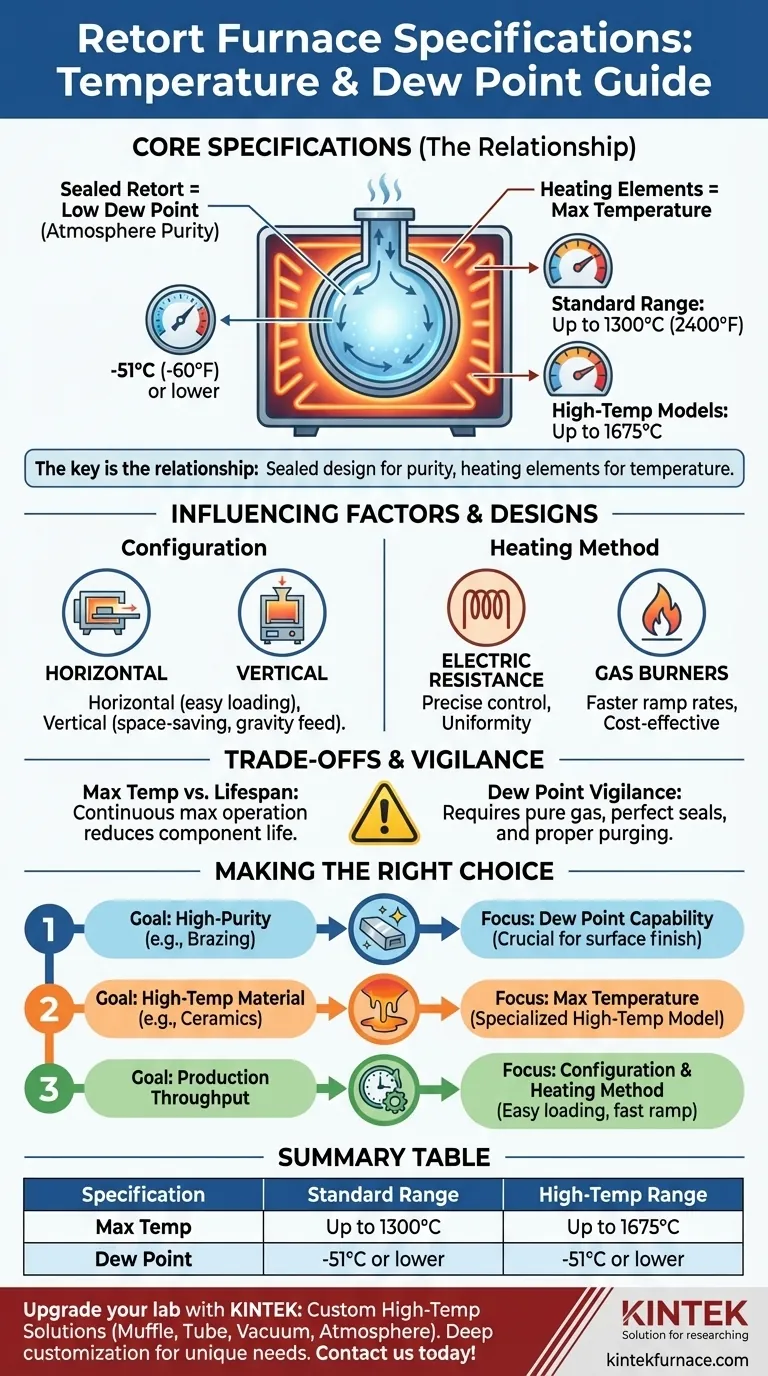

At a minimum, a standard retort furnace can achieve maximum temperatures of 1300°C (2400°F) and maintain a very low dew point of -51°C (-60°F) or better. However, the term "retort furnace" covers a range of designs, with specialized high-temperature models capable of reaching up to 1675°C, demonstrating that the exact specification depends heavily on the unit's construction and intended purpose.

The key takeaway is not a single set of numbers, but an understanding of the relationship between them. The sealed retort design is what enables the critically low dew point for atmosphere purity, while the maximum temperature is determined by the furnace's heating elements and construction materials.

Deconstructing the Core Specifications

A retort furnace's value comes from its ability to precisely control both temperature and atmosphere. Understanding these two key specifications is essential to matching the equipment to your process.

The Operating Temperature Range

The maximum temperature of a retort furnace is not a single standard. It falls into a spectrum defined by its construction.

Standard models typically operate up to 1300°C (2400°F). This range is sufficient for a wide variety of heat-treating applications like brazing, annealing, and sintering many common materials.

High-temperature models can push this limit significantly higher, reaching up to 1675°C. These furnaces use more robust heating elements and retort materials to handle the extreme thermal stress.

The Critical Role of Dew Point

The dew point specification is arguably the most important feature of a retort furnace. It measures the amount of water vapor in the process atmosphere.

A dew point of -51°C (-60°F) or lower signifies an extremely dry, high-purity inert atmosphere. This is crucial for preventing oxidation on the surface of parts during high-temperature processing.

Achieving this low dew point is the primary function of the sealed retort vessel, which isolates the workload from outside air and moisture.

Factors That Influence Performance

The headline specifications for temperature and dew point are influenced by the fundamental design of the furnace.

Furnace Configuration

Retort furnaces are commonly built in two main configurations: horizontal and vertical.

A horizontal retort is the most common design, allowing for easy loading and unloading of parts on trays. A vertical retort is often used for applications with limited floor space or for processes that benefit from gravity, such as feeding powders.

While the configuration does not inherently limit the maximum temperature, it dictates how material is handled and the overall process workflow.

Heating Method

The furnace can be heated using two primary methods: electric resistance heaters or gas burners.

Electric heating generally provides more precise temperature control and uniformity, which is critical for sensitive processes.

Gas heating can offer faster ramp rates and may be more cost-effective in some operational contexts, but it can be more challenging to maintain precise atmospheric conditions.

Understanding the Trade-offs

Selecting a furnace based on its maximum specifications alone can be misleading. It's crucial to understand the practical limitations and operational costs.

High Temperature vs. Component Lifespan

Consistently operating a furnace at its absolute maximum rated temperature will drastically reduce the lifespan of the heating elements, insulation, and the retort itself. A furnace rated for 1300°C will have a much longer operational life if it is typically run at 1200°C.

Achieving Low Dew Point Requires Vigilance

A low dew point is not automatic. It depends on several factors: the purity of the incoming process gas (like argon or nitrogen), the integrity of all seals, and proper purging procedures to remove all oxygen and moisture before the cycle begins. Even a small leak can compromise the entire atmosphere.

Making the Right Choice for Your Process

Use the core specifications to guide your selection based on the primary goal of your thermal process.

- If your primary focus is high-purity processing (e.g., bright annealing, brazing): The dew point capability is your most critical specification, as it directly impacts surface finish and prevents oxidation.

- If your primary focus is high-temperature material processing (e.g., sintering advanced ceramics): The maximum operating temperature is your key metric, and you will likely need a specialized, high-temperature model.

- If your primary focus is production throughput: The furnace configuration (horizontal for easy loading) and heating method (gas for faster ramp-up) become central to your decision.

Understanding these core principles empowers you to select a retort furnace that precisely matches your technical and operational requirements.

Summary Table:

| Specification | Standard Range | High-Temperature Range |

|---|---|---|

| Maximum Temperature | Up to 1300°C (2400°F) | Up to 1675°C |

| Dew Point | -51°C (-60°F) or lower | -51°C (-60°F) or lower |

Upgrade your lab with precision and reliability! KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for high-purity processing and temperature control. Contact us today to discuss how we can enhance your thermal processes!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments