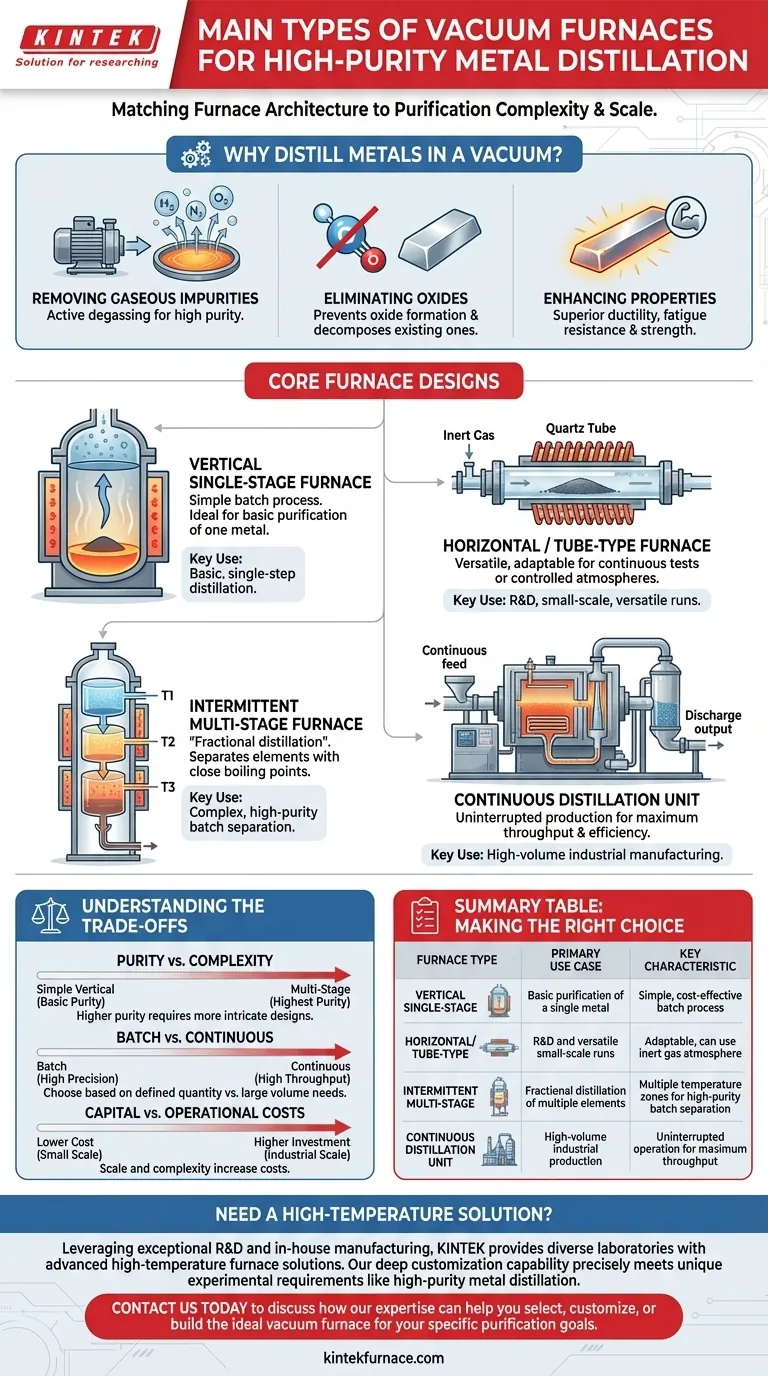

The primary types of vacuum furnaces for metal distillation are the vertical single-stage, horizontal tube-type, intermittent multi-stage, and continuous distillation units. Each design is engineered to solve a specific challenge, from simple batch purification to complex, industrial-scale fractional separation of multiple elements.

The choice of a vacuum distillation furnace is dictated entirely by two factors: the complexity of the purification task and the required production scale. The furnace architecture directly corresponds to the level of separation needed and the desired operational throughput.

The Principle: Why Distill Metals in a Vacuum?

Before examining specific furnace types, it's crucial to understand why a vacuum environment is so effective for metal purification. The vacuum is not just an empty space; it is an active tool for refining metals to exceptional purity levels.

Removing Gaseous Impurities

The vacuum environment actively draws out trapped gases like hydrogen, nitrogen, and oxygen from the molten metal. This degassing process is fundamental to producing high-purity metals.

Eliminating Oxides

By removing oxygen, a vacuum prevents the formation of unwanted oxides. It can also cause existing, less-stable oxides to decompose, further cleaning the metal and improving its final quality.

Enhancing Material Properties

The resulting purified metal exhibits superior mechanical properties, such as improved ductility, fatigue resistance, and overall strength, compared to metals processed using conventional methods.

Core Furnace Designs for Metal Distillation

The design of a vacuum furnace directly enables a specific type of purification. The main variations center on the number of temperature zones and the method of material handling (batch versus continuous).

Vertical Single-Stage Furnace

This is the most fundamental design, featuring a single heating and condensation zone. It is ideal for simple purification tasks where the goal is to separate a primary metal from impurities with significantly different boiling points.

Its straightforward operation makes it a workhorse for basic, single-step distillation in a batch process.

Horizontal or Tube-Type Furnace

This design often uses a quartz tube as the main chamber. The horizontal orientation can help mitigate the effects of gravity on the separation process.

These furnaces offer versatility and are often adapted for continuous production tests or for operation under a controlled inert gas atmosphere to prevent re-contamination.

Intermittent Multi-Stage Furnace

For more complex separations, this furnace is the definitive choice. It is engineered with multiple condensation zones, each maintained at a different, precisely controlled temperature.

This "fractional distillation" approach allows various impurities and the primary metal to condense separately along the temperature gradient. It enables the separation of elements with closer boiling points in a single, highly effective batch operation.

Continuous Distillation Units

Designed for industrial-scale operations, these units are built for uninterrupted production. They feature dedicated feeding systems to introduce raw material and discharge systems to remove purified metal and waste products without breaking the vacuum.

This design maximizes throughput and efficiency, making it the standard for high-volume manufacturing of high-purity metals.

Understanding the Trade-offs

Selecting a furnace involves balancing complexity, cost, and purification capability. There is no single "best" type; the optimal choice depends entirely on the specific application and its constraints.

Purity vs. Complexity

A simple vertical furnace is effective for basic purification but cannot perform fractional separation. Achieving the highest levels of purity for complex alloys requires the more intricate and difficult-to-operate multi-stage furnace.

Batch vs. Continuous Processing

Batch systems, like the intermittent multi-stage furnace, offer high precision and are excellent for complex separations of a defined quantity. Continuous systems prioritize throughput and efficiency for producing large volumes of a single, purified metal.

Capital and Operational Costs

As a rule, increased complexity and scale directly correlate with higher costs. A continuous industrial unit represents a significant capital investment compared to a simple, lab-scale vertical furnace.

Making the Right Choice for Your Goal

Your specific purification goal is the ultimate guide to selecting the appropriate furnace technology.

- If your primary focus is basic purification of a single metal from simple impurities: The vertical single-stage furnace provides a reliable and cost-effective solution.

- If your primary focus is separating multiple elements with different boiling points in a single batch: The intermittent multi-stage furnace is specifically designed for this type of fractional distillation.

- If your primary focus is high-volume, uninterrupted industrial production: The continuous distillation unit is the only design that meets the demands of large-scale manufacturing.

- If your primary focus is research, development, or small-scale runs requiring high versatility: The horizontal tube-type furnace offers an adaptable platform for various processes.

By matching the furnace architecture to the specific metallurgical challenge, you gain precise control over the final purity and properties of your material.

Summary Table:

| Furnace Type | Primary Use Case | Key Characteristic |

|---|---|---|

| Vertical Single-Stage | Basic purification of a single metal | Simple, cost-effective batch process |

| Horizontal/Tube-Type | R&D and versatile small-scale runs | Adaptable, can use inert gas atmosphere |

| Intermittent Multi-Stage | Fractional distillation of multiple elements | Multiple temperature zones for high-purity batch separation |

| Continuous Distillation Unit | High-volume industrial production | Uninterrupted operation for maximum throughput |

Need a High-Temperature Solution for Your Metal Purification Process?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements like high-purity metal distillation.

Contact us today to discuss how our expertise can help you select, customize, or build the ideal vacuum furnace for your specific purification goals.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the purpose of performing medium vacuum annealing on working ampoules? Ensure Pure High-Temp Diffusion

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What processing conditions does a vacuum furnace provide for TiCp/Fe microspheres? Sintering at 900 °C

- What is the role of sintering or vacuum induction furnaces in battery regeneration? Optimize Cathode Recovery