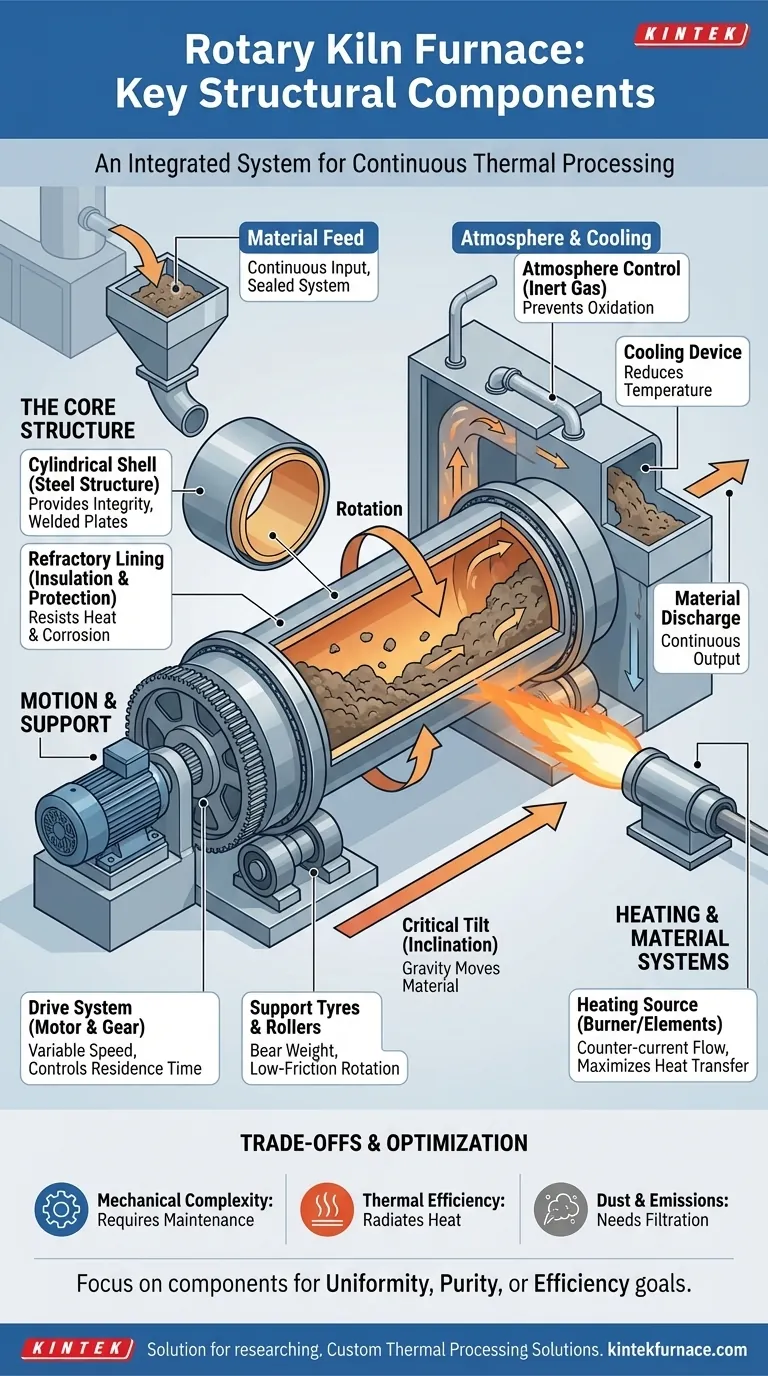

At its core, a rotary kiln furnace is an integrated system designed for the continuous thermal processing of materials. Its key structural components are the cylindrical shell, the internal refractory lining that protects it, the drive system that provides rotation, the support structure that holds it at an incline, and the heating system that provides the necessary energy.

A rotary kiln is more than just a hot, rotating tube. It is a dynamic processing machine where each component—from the shell's angle of inclination to the type of refractory lining—is engineered to work in concert, ensuring material is continuously mixed, heated uniformly, and transported from input to output.

The Core Structure: The Rotating Cylinder

The most recognizable feature of a rotary kiln is its massive cylindrical body. This structure is not a simple container but a carefully engineered component responsible for holding and transporting the material.

The Shell (or Retort)

The shell is the external steel body of the furnace. It provides the primary structural integrity for the entire system.

These shells can be enormous, sometimes reaching lengths of over 200 meters, and are constructed from welded steel plates to withstand the immense mechanical stresses of rotation and weight.

The Refractory Lining

Inside the steel shell is a critical layer of refractory material. This lining serves two primary functions: insulating the shell from extreme internal temperatures and protecting it from chemical corrosion or abrasion from the process material.

The choice of refractory—whether bricks, castable cement, or other moldable substances—depends entirely on the maximum temperature and the chemical nature of the material being processed.

Enabling Motion and Support

The kiln's rotation and incline are what make it a continuous-process machine. These functions are managed by a robust system of mechanical components.

The Drive System

The drive system provides the rotational force. This typically consists of a large motor connected to a gear assembly (a "drive gear" or "girth gear") that encircles the kiln's shell.

Modern systems feature variable speed control, allowing operators to precisely adjust the rotation speed. This control is crucial for managing how long the material stays in the kiln (residence time) and how well it is mixed.

The Support Tyres and Rollers

Due to its immense weight, the kiln cannot support itself. It rests on massive steel rings, known as tyres or riding rings, which are fitted around the shell.

These tyres rotate on a series of heavy-duty rollers (or "trunnions"), which bear the full load of the kiln and allow it to turn with minimal friction.

The Critical Tilt (Inclination)

Rotary kilns are always mounted at a slight angle to the horizontal. This inclination is the mechanism that moves material through the furnace.

As the kiln rotates, gravity pulls the material slowly from the higher feed end down to the lower discharge end. The precise angle of this tilt is a key operational parameter for controlling the speed of material flow.

The Heart of the Process: The Heating and Material Systems

The ultimate purpose of the kiln is to apply heat. This is achieved through a dedicated heating system, while other components manage the material and internal environment.

The Heating Source

Heat is typically generated by a powerful burner located at the lower (discharge) end of the kiln, firing gas or other fuels into the chamber. In other designs, electric heating elements may be used.

The hot gases flow up the kiln, typically in the opposite direction of the material flow (counter-current flow), to maximize heat transfer efficiency.

Material Feed and Discharge

Specialized systems are required to continuously introduce raw material into the feed end and remove the processed product from the discharge end. These systems are designed to maintain a seal, preventing heat loss or unwanted air from entering the kiln.

Atmosphere and Cooling Control

For processes requiring high purity, such as in lithium battery material production, an atmosphere control system is used. This involves feeding inert gases like nitrogen or argon into the kiln to prevent oxidation or other unwanted reactions.

After discharge, the hot material must be cooled. This is handled by a separate cooling device, which can be either water-cooled or air-cooled, to bring the product to a safe temperature.

Understanding the Trade-offs

While highly effective, the design of a rotary kiln presents inherent challenges that are critical to understand for proper operation and maintenance.

Mechanical Complexity

The sheer number of heavy, moving parts—including the drive gear, support rollers, and bearings—makes a rotary kiln mechanically complex. This requires a rigorous preventative maintenance schedule to ensure reliability and avoid costly downtime.

Thermal Inefficiency

Due to their large surface area, kiln shells radiate a significant amount of heat into the surrounding environment. Without excellent insulation and process control, they can be less energy-efficient than some batch furnace designs.

Dust and Emissions

The tumbling action that makes rotary kilns excellent mixers can also generate a great deal of dust, especially with fine powders. This necessitates sophisticated air filtration and dust collection systems to meet environmental regulations and prevent product loss.

Making the Right Choice for Your Goal

Understanding these components allows you to focus on the elements most critical to your specific processing objective.

- If your primary focus is process uniformity: The controlled rotation speed and the precise inclination angle are your most important parameters, as they dictate mixing intensity and residence time.

- If your primary focus is material purity: The choice of refractory lining and the effectiveness of the atmosphere control system are paramount to preventing contamination and unwanted chemical reactions.

- If your primary focus is operational efficiency: The reliability of the drive system and the energy consumption of the heating source will be your main areas of concern for minimizing maintenance and cost.

By viewing the rotary kiln as a system of interconnected parts, you can better diagnose issues, optimize performance, and achieve your desired product quality.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Cylindrical Shell | Provides structural integrity and houses materials | Made of welded steel, withstands mechanical stress |

| Refractory Lining | Insulates and protects from heat and corrosion | Customizable based on temperature and material type |

| Drive System | Enables rotation for material mixing and transport | Variable speed control for precise residence time |

| Support Tyres and Rollers | Supports kiln weight and allows rotation | Heavy-duty steel rings and rollers for minimal friction |

| Heating System | Applies heat for thermal processing | Uses burners or electric elements, often counter-current flow |

| Material Feed/Discharge | Manages input and output of materials | Maintains seals to prevent heat loss and contamination |

| Atmosphere Control | Regulates internal environment for purity | Uses inert gases to prevent oxidation in sensitive processes |

Ready to optimize your thermal processing with a custom rotary kiln solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're focused on process uniformity, material purity, or operational efficiency, our solutions ensure reliable performance and enhanced productivity. Contact us today to discuss how we can help you achieve superior results in your laboratory!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes