At its core, the Plasma-Enhanced Chemical Vapor Deposition (PECVD) process involves five distinct steps. It begins with introducing reactant gases into a vacuum chamber, followed by applying an electric field to generate a plasma. Reactive species from this plasma then travel to the substrate surface, undergo chemical reactions to form a solid film, and finally, gaseous by-products are pumped away.

PECVD is not just a sequence of steps; it is a strategic solution to a fundamental problem in materials science. By using an energy-rich plasma instead of high heat, it enables the creation of high-quality thin films at low temperatures, making it possible to coat materials that would be damaged by traditional deposition methods.

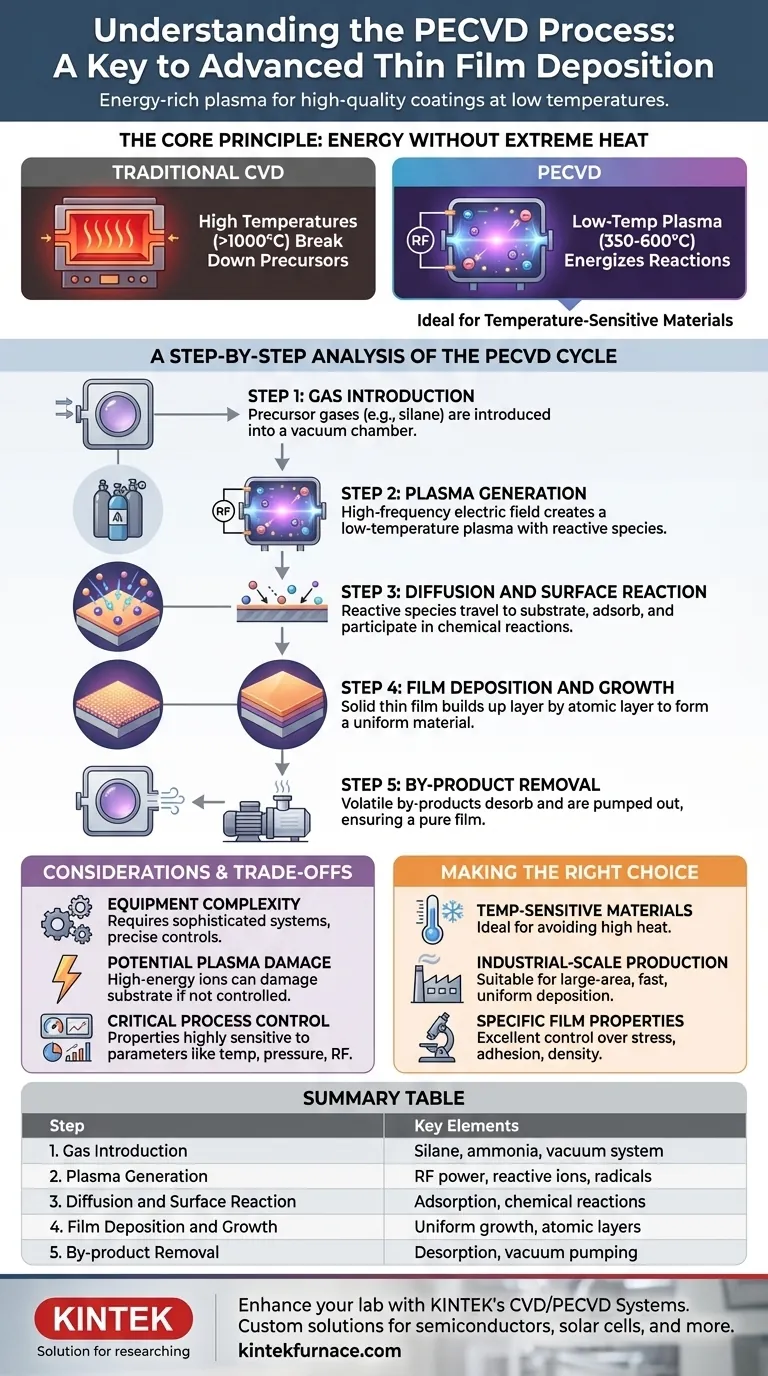

The Core Principle: Energy Without Extreme Heat

In traditional Chemical Vapor Deposition (CVD), extremely high temperatures are required to provide the energy needed to break down precursor gases and initiate chemical reactions on a substrate.

PECVD fundamentally changes this energy dynamic. Instead of relying solely on thermal energy, it introduces energy through an electric field, typically at a radio frequency (RF). This field ignites the low-pressure gas into a plasma, an ionized state of matter containing a mix of electrons, ions, and highly reactive neutral species.

This plasma becomes the engine of the deposition process. The reactive species it contains have enough energy to react and form a film at significantly lower substrate temperatures, often in the 350-600°C range, compared to the 1000°C or more required by some thermal CVD processes.

A Step-by-Step Analysis of the PECVD Cycle

Each step in the PECVD process is carefully controlled to ensure the final film meets precise specifications for thickness, composition, and quality.

Step 1: Gas Introduction

After a substrate is placed inside the reaction chamber and a vacuum is established, one or more precursor gases are introduced. These gases contain the atoms required for the final film (e.g., silane for silicon films, or silane and ammonia for silicon nitride films).

Step 2: Plasma Generation

A high-frequency electric field is applied across the electrodes in the chamber. This field energizes the gas molecules, stripping electrons and creating a glowing, low-temperature plasma filled with chemically reactive ions and radicals.

Step 3: Diffusion and Surface Reaction

The highly reactive species generated in the plasma diffuse—or travel—through the vacuum and bombard the substrate surface. Once there, they adsorb (stick to the surface) and participate in a series of chemical reactions.

Step 4: Film Deposition and Growth

The products of these surface reactions are engineered to be a non-volatile solid material. This material builds up on the substrate, layer by atomic layer, forming a uniform and solid thin film.

Step 5: By-product Removal

The chemical reactions also create volatile by-products that must be removed. These gaseous waste products desorb from the surface and are continuously pumped out of the chamber by the vacuum system, ensuring a pure and uncontaminated film.

Understanding the Trade-offs and Considerations

While powerful, PECVD is not a universal solution. Understanding its limitations is key to using it effectively.

Equipment Complexity

PECVD systems are more complex than some other deposition methods. They require a sophisticated vacuum chamber, precise gas flow controllers, and a stable RF power source and matching network, which can represent a significant capital investment.

Potential for Plasma Damage

The high-energy ions that make the process so effective can also cause damage to the substrate or the growing film if not properly controlled. Optimizing plasma power and gas pressure is critical to balance deposition rate with film quality and minimize ion-induced defects.

Process Control is Critical

The final properties of the deposited film—such as stress, density, and chemical composition—are highly sensitive to process parameters. Small variations in temperature, pressure, gas flow rates, or RF power can significantly alter the outcome, requiring meticulous process development and control.

Making the Right Choice for Your Goal

Deciding if PECVD is the right tool depends entirely on your specific material and performance requirements.

- If your primary focus is coating temperature-sensitive materials: PECVD is an ideal choice because its plasma-based energy source avoids the high heat of traditional CVD.

- If your primary focus is industrial-scale production: The ability of PECVD to handle large-area substrates and achieve fast, uniform deposition makes it highly suitable for manufacturing solar cells, displays, and semiconductors.

- If your primary focus is achieving specific film properties: PECVD offers excellent control over film stress, adhesion, and density through precise tuning of its plasma and process parameters.

Ultimately, PECVD provides a powerful and versatile method for engineering advanced surfaces when thermal constraints and film quality are paramount.

Summary Table:

| Step | Description | Key Elements |

|---|---|---|

| 1. Gas Introduction | Precursor gases are introduced into a vacuum chamber. | Silane, ammonia, vacuum system |

| 2. Plasma Generation | Electric field creates a low-temperature plasma. | RF power, reactive ions, radicals |

| 3. Diffusion and Surface Reaction | Reactive species travel and adsorb on the substrate. | Adsorption, chemical reactions |

| 4. Film Deposition and Growth | Solid thin film forms layer by layer on the substrate. | Uniform growth, atomic layers |

| 5. By-product Removal | Volatile by-products are pumped out of the chamber. | Desorption, vacuum pumping |

Ready to enhance your lab's capabilities with advanced PECVD solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace solutions like our CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs for semiconductors, solar cells, and more—ensuring superior film quality and efficiency. Contact us today to discuss how we can support your PECVD process goals!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency