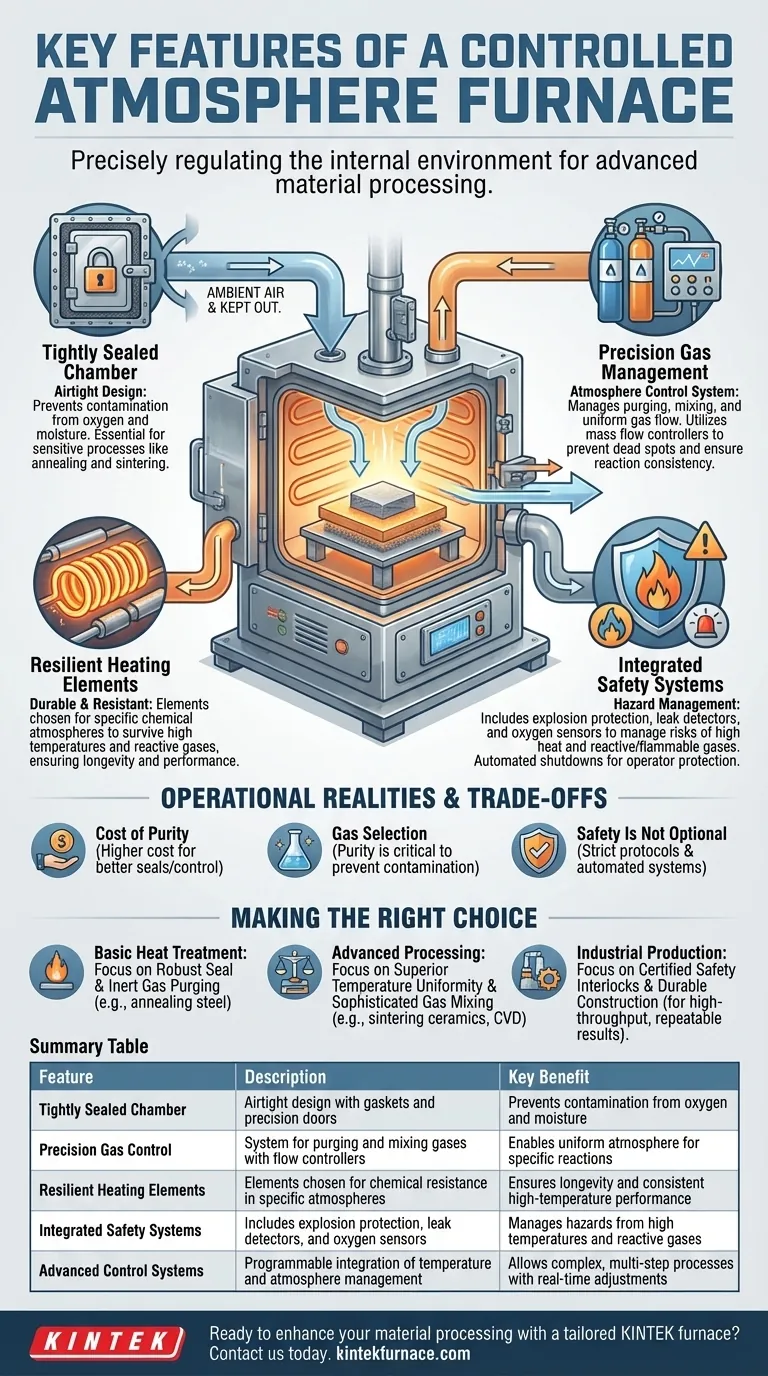

At its core, a controlled atmosphere furnace is a high-temperature chamber engineered to replace the natural air inside with a specific, highly regulated gas environment. Its key features are a tightly sealed chamber to prevent contamination, a precision gas control system for managing the internal atmosphere, durable heating elements designed for specific chemical environments, and integrated safety systems to manage the potential hazards of high temperatures and reactive gases.

The purpose of a controlled atmosphere furnace is not just to get hot, but to act as a precise chemical reactor. Its features work in unison to eliminate unwanted variables like oxygen, enabling specific material transformations that would be impossible in open air.

The Core Principle: Creating an Isolated Environment

A furnace's primary job is to create a perfect, isolated world for your material. This begins with removing the outside world entirely.

The Imperative of a Tightly Sealed Chamber

The single most critical feature is the furnace's ability to seal completely. Any leak allows oxygen and moisture from the ambient air to infiltrate the chamber.

This contamination can ruin sensitive processes like annealing or sintering by causing unwanted oxidation. High-quality furnaces use robust gaskets and precision-machined doors to ensure an airtight environment.

Precision Gas Management Systems

Once sealed, the ambient air must be purged and replaced. This is handled by a gas inlet and outlet system.

A simple system might just flush the chamber with an inert gas like argon or nitrogen. More advanced systems use mass flow controllers to precisely mix gases and ensure uniform atmosphere flow, preventing dead spots where reactions could fail.

Achieving and Maintaining Process Conditions

With the environment isolated, the furnace must then execute the specific temperature and atmospheric profile required by the process.

Resilient Heating Elements

Heating elements must not only reach the target temperature but also survive the chemical atmosphere inside.

A standard heating element might quickly degrade in a carbon-rich or reducing atmosphere. Therefore, elements are chosen based on their resistance to the specific gases being used, ensuring longevity and process consistency.

Advanced Control Systems

Modern furnaces integrate temperature and atmosphere management into a single, programmable system. Thermocouples provide real-time temperature feedback to a PID controller, which precisely adjusts power to the heating elements.

Simultaneously, the atmosphere control system can be programmed to change gas flow rates or compositions at different stages of the heating and cooling cycle, enabling complex, multi-step processes.

Understanding the Trade-offs and Operational Realities

While powerful, these furnaces present unique operational challenges. Understanding them is key to successful and safe operation.

The Cost of Purity

A better seal and more precise gas control directly translate to higher equipment costs. For basic applications, a simple flush system may suffice. For advanced materials research, a high-vacuum-capable furnace with mass flow controllers is non-negotiable.

Gas Selection and Management

The furnace is only one part of the equation. The purity of the source gases is critical. Using low-purity gas can introduce contaminants, defeating the purpose of the controlled environment.

Safety Is Not Optional

These furnaces operate at extreme temperatures and often use hazardous gases. Flammable gases like hydrogen require explosion protection devices and leak detectors. Asphyxiant gases like nitrogen and argon require oxygen sensors in the lab space.

Automated safety systems are a key feature, designed to monitor for abnormalities and trigger alarms or automatic shutdowns to protect both the operator and the equipment.

Making the Right Choice for Your Goal

The ideal furnace depends entirely on the process you need to run. Your application dictates the necessary features.

- If your primary focus is basic heat treatment (like annealing steel): Prioritize a furnace with a robust seal and a reliable inert gas purging system to prevent surface oxidation.

- If your primary focus is advanced material processing (like sintering ceramics or CVD): You need superior temperature uniformity and a sophisticated gas mixing and flow control system.

- If your primary focus is process safety and industrial production: Emphasize certified safety interlocks, automated process control, and durable construction for high-throughput, repeatable results.

Ultimately, selecting the right furnace means matching its environmental control capabilities to the precise chemical requirements of your material process.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Tightly Sealed Chamber | Airtight design with gaskets and precision doors | Prevents contamination from oxygen and moisture |

| Precision Gas Control | System for purging and mixing gases with flow controllers | Enables uniform atmosphere for specific reactions |

| Resilient Heating Elements | Elements chosen for chemical resistance in specific atmospheres | Ensures longevity and consistent high-temperature performance |

| Integrated Safety Systems | Includes explosion protection, leak detectors, and oxygen sensors | Manages hazards from high temperatures and reactive gases |

| Advanced Control Systems | Programmable integration of temperature and atmosphere management | Allows complex, multi-step processes with real-time adjustments |

Ready to enhance your material processing with a tailored controlled atmosphere furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our furnaces can optimize your lab's efficiency and safety!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing